Self-crosslinked one-component polyurethane waterproofing coating

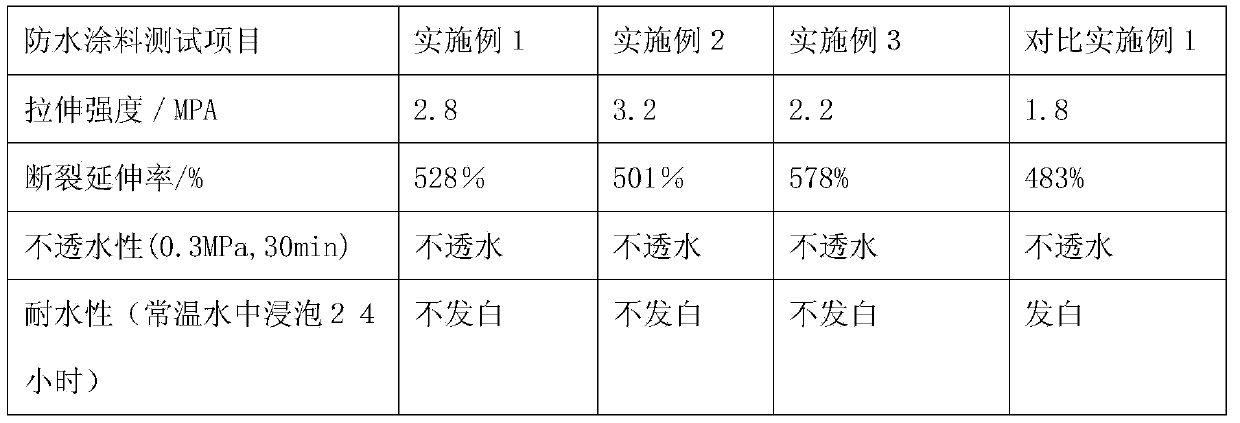

A waterproof coating and self-crosslinking technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor water resistance of water-based coatings, and achieve excellent mechanical properties, water resistance, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1000 grams of polyoxypropylene ether diol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105-115°C, and dehydrate for 1-4 hours under the condition of vacuum degree of -0.08-0.1MPa, add 290 grams of toluene diisocyanate, 40 grams of 1,4-butanediol, 50 grams of dimethylol propionic acid, 20 grams of self-made diethanolamine diacetone propionamide and 1 gram of dibutyltin dilaurate, continue to stir, at 80 ℃ Keep warm and react for 8 hours; after cooling down to below 50°C, add 100 grams of acetone and emulsify under high-speed stirring; add 30 grams of isophorone diamine and continue stirring for 1 to 2 hours; heat up to 60°C, The solvent is removed for 2 hours under the condition of vacuum degree of -0.08-0.1MPa; 6g of adipic hydrazide is added at room temperature, stirred for 1 hour until uniform, and the waterproof coating of the present invention is obtained after discharging.

Embodiment 2

[0020] 1000 grams of polyoxypropylene ether diol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105-115°C, and dehydrate for 1-4 hours under the condition of vacuum degree of -0.08-0.1MPa, add 417 grams of diphenylmethane diisocyanate, 40 grams of 1,4-butanediol, 50 grams of dimethylolpropionic acid, 20 grams of homemade diethanolamine diacetone propionamide and 1 gram of dibutyltin dilaurate, continue to stir, Insulate and react at 80°C for 8 hours; after cooling down to below 50°C, add 100 grams of acetone and emulsify with water under high-speed stirring; add 30 grams of isophorone diamine and continue stirring for 1 to 2 hours; heat up to 60 °C, desolventize for 2 hours under the condition of vacuum degree of -0.08 ~ 0.1MPa; add 6g of adipic dihydrazide at room temperature, stir for 1 hour until uniform, and discharge the material to obtain the waterproof coating of the present invention.

Embodiment 3

[0022] 1000 grams of polyoxypropylene ether diol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105-115°C, and dehydrate for 1-4 hours under the condition of vacuum degree of -0.08-0.1MPa, add 370 g of isophorone diisocyanate, 40 g of 1,4-butanediol, 50 g of acetone and dimethylolpropionic acid, 20 g of homemade diethanolamine diacetone propionamide and 1 g of dibutyltin dilaurate, continued Stir and keep warm at 80°C for 8 hours; after cooling down to below 50°C, add 100 grams of acetone and emulsify under water under high-speed stirring conditions; add 30 grams of isophorone diamine and continue stirring for 1 to 2 hours; heat up To 60°C, desolventize for 2 hours under the condition of vacuum degree of -0.08~0.1MPa; add 6g of adipic hydrazide at room temperature, stir for 1 hour until uniform, and discharge the material to obtain the waterproof coating of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com