A self-crosslinking type one-component polyurethane waterproof coating

A waterproof coating and self-crosslinking technology, which is applied in the field of architectural coatings, can solve the problems of poor water resistance of water-based coatings, and achieve excellent mechanical properties, water resistance, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

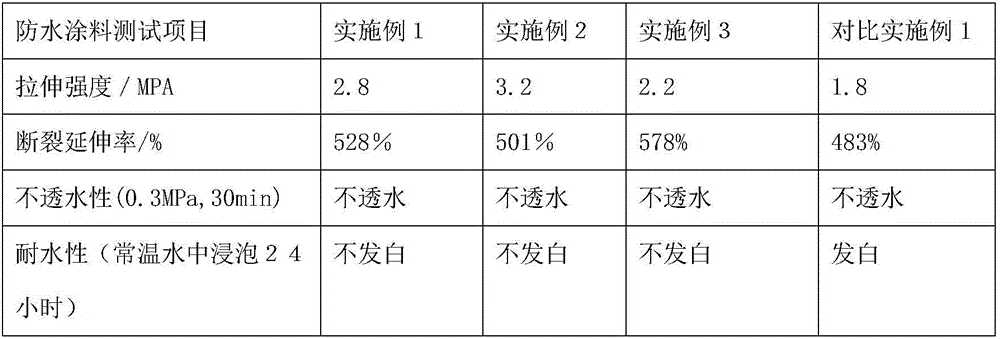

Examples

Embodiment 1

[0018] 1000 grams of polyoxypropylene ether glycol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105~115℃, and the vacuum degree of dehydration for 1-4 hours under the condition of -0.08~0.1MPa, add 290 grams of toluene diisocyanate, 40 grams of 1,4-butanediol, 50 grams of dimethylolpropionic acid, 20 grams of homemade diethanolamine diacetone propionamide and 1 gram of dibutyltin dilaurate, continue to stir, at 80°C Incubate and react for 8 hours after cooling down; add 100 grams of acetone and emulsify under water under high-speed stirring conditions when the temperature is below 50°C; add 30 grams of isophorone diamine and continue stirring for 1 to 2 hours; increase the temperature to 60°C, The solvent is removed for 2 hours under the condition of vacuum degree of -0.08~0.1MPa; 6g adipic acid hydrazide is added at normal temperature, stirred for 1 hour until uniform, and the waterproof coating of the present invention is obt...

Embodiment 2

[0020] 1000 grams of polyoxypropylene ether glycol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105~115℃, and the vacuum degree of dehydration for 1-4 hours under the condition of -0.08~0.1MPa, add 417 grams of diphenylmethane diisocyanate, 40 grams of 1,4-butanediol, 50 grams of dimethylolpropionic acid, 20 grams of homemade diethanolamine diacetone propionamide and 1 gram of dibutyltin dilaurate, continue to stir, Incubate the reaction at 80°C for 8 hours; after cooling down to below 50°C, add 100 grams of acetone and emulsify under water under high-speed stirring conditions; add 30 grams of isophorone diamine and continue to stir for 1 to 2 hours; increase the temperature to 60 ℃, the solvent is removed for 2 hours under the condition of vacuum degree of -0.08~0.1MPa; 6g adipic acid hydrazide is added at normal temperature, stirred for 1 hour until uniform, and the waterproof coating of the present invention is obtained afte...

Embodiment 3

[0022] 1000 grams of polyoxypropylene ether glycol, 400 grams of polyoxypropylene ether triol, 100 grams of plasticizer, control the temperature at 105~115℃, and the vacuum degree of dehydration for 1-4 hours under the condition of -0.08~0.1MPa, add 370 grams of isophorone diisocyanate, 40 grams of 1,4-butanediol, 50 grams of acetone and dimethylolpropionic acid, 20 grams of homemade diethanolamine diacetone propionamide and 1 gram of dibutyl tin dilaurate, continue Stir, keep the temperature at 80℃ for 8 hours; after cooling down to below 50℃, add 100 grams of acetone and emulsify under water under high-speed stirring; add 30 grams of isophorone diamine and continue stirring for 1 to 2 hours; To 60°C, the solvent is removed for 2 hours under the condition of a vacuum degree of -0.08~0.1MPa; 6g adipic acid hydrazide is added at normal temperature, and the mixture is stirred for 1 hour until uniform, and the waterproof coating of the present invention is obtained after dischargin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com