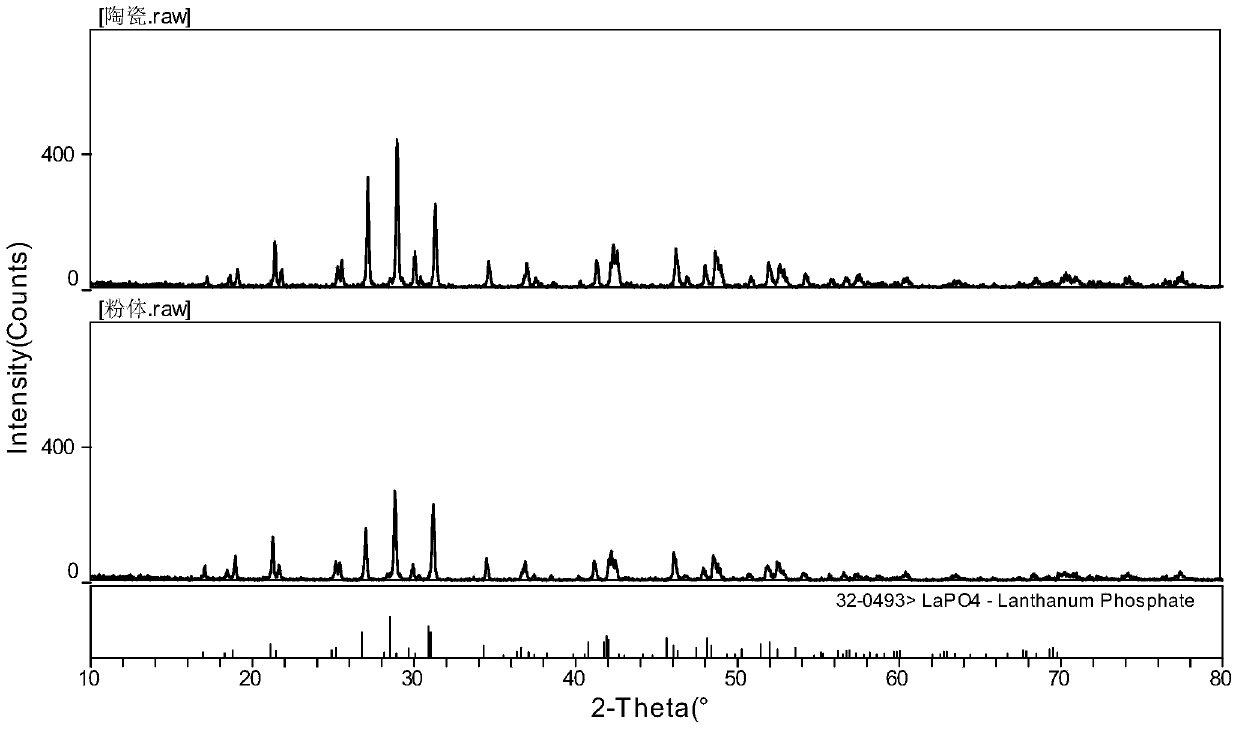

Preparation method of lanthanum phosphate ceramic fluorescent material

A fluorescent material, the technology of lanthanum phosphate, applied in the field of preparation of lanthanum phosphate ceramic fluorescent material, can solve the problems of long holding time, instability, high preparation temperature, etc., and achieve the effects of reducing holding time, bright output and transmission, and lowering sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the present invention.

[0026] A method for preparing a lanthanum phosphate ceramic fluorescent material, characterized in that it comprises the following steps:

[0027] Step 1, preparation of precursor:

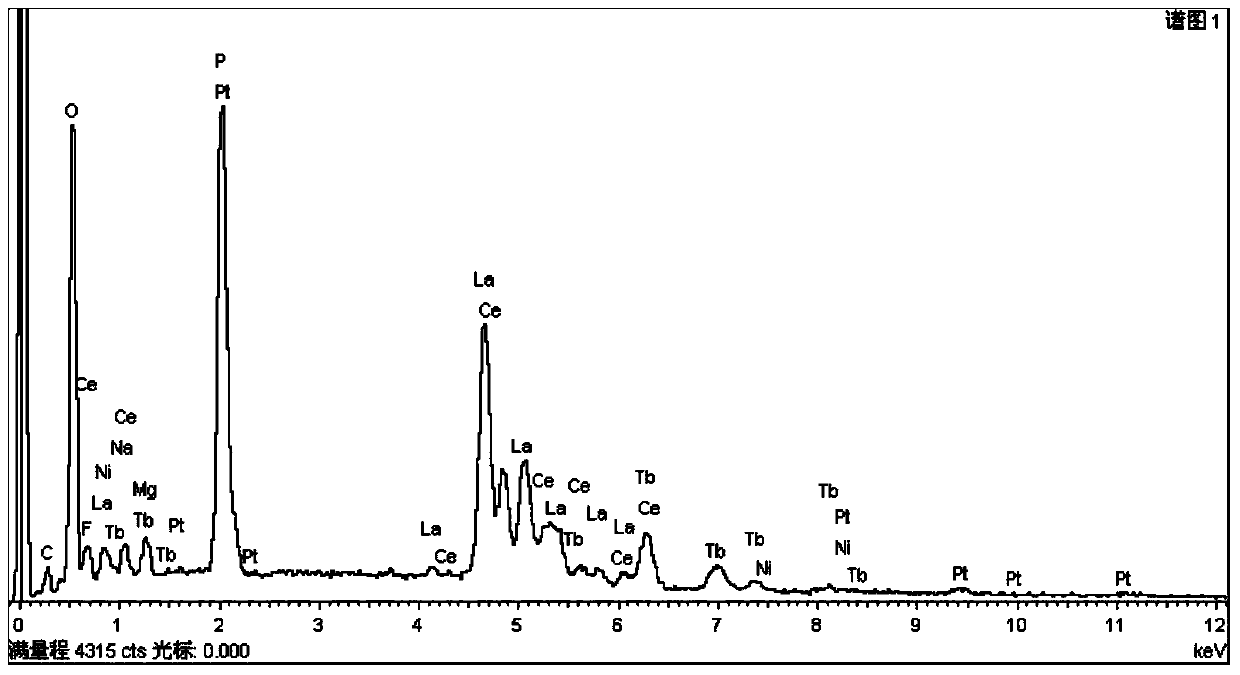

[0028] Take La 2 o 3 , CeO 2 , Tb 4 o 7 with (NH 4 ) 2 HPO 4 Four medicines, the molar ratio is 0.5-0.9:0.4-0.05:0.3-0.05:1-2. La 2 o 3 Mix it with concentrated nitric acid at a molar ratio of 1:10 to 40, and mix CeO 2 Mix with concentrated nitric acid at a molar ratio of 1:5-20, and mix Tb 4 o 7 Mix it with concentrated nitric acid at a molar ratio of 1:20-70, and add 5%-30% solution volume of hydrogen peroxide to the above three liquids to completely dissolve it. Then, the three solutions were pressed by La 2 o 3 , CeO 2 , Tb 4 o 7 mixed in order. The pH value of the above mixed solution is adjusted between 1 and 4 with ammonia water. Take (NH 4 ) 2 HPO 4 Solid, make it disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com