Rare earth-magnesium-nickel system heterogeneous hydrogen storage alloys used for nickel-hydrogen batteries and preparing method thereof

A nickel-metal hydride battery and hydrogen storage alloy technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems affecting the price of final products and high prices, and achieve the goal of improving self-discharge and low-temperature performance, increasing discharge capacity and cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

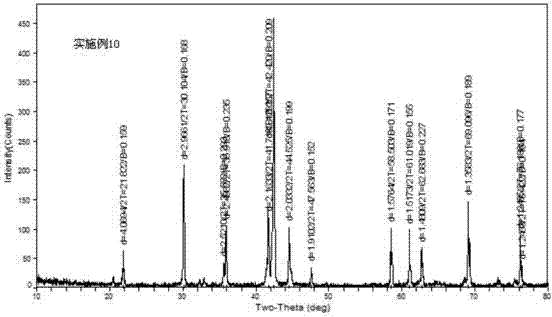

[0021] According to the structural formula La 0.40 Ce 0.05 SM 0.05 Mg 0.45 Ni 4.30 al 0.20 co 0.40 mn 0.30 Ag 0.15 Weigh the metal raw materials La, Ce, Sm, Mg, Ni, Al, Co, Mn, Ag, put them in the crucible of the induction melting furnace, vacuumize (0.1Pa) and fill it with argon gas. The pressure is 0.1MPa, smelting at 1400K for 20 hours to obtain a metal smelting solution; pour the metal smelting solution into a water-cooled ingot mold and cool to obtain an alloy ingot. Place the alloy ingot in a horizontal heat treatment furnace, vacuumize (0.1Pa) and fill it with protective gas argon, the pressure in the furnace is 0.05MPa, anneal at 1000K for 48 hours, and jet crush to obtain rare earth-magnesium for nickel-metal hydride batteries - Nickel-based multiphase superlattice hydrogen storage alloy. XRD test showed that AB 5 Phase accounted for 10.0%, A 2 B 7 phase accounts for 90.0%, and no other phase exists.

Embodiment 3

[0023] According to the structural formula La 0.45 Ce 0.10 SM 0.10 Mg 0.40 Ni 4.00 al 0.20 co 0.50 mn 0.40 Ge 0.02 Weigh the metal raw materials La, Ce, Sm, Mg, Ni, Al, Co, Mn, Ge, put them all in the crucible of the induction melting furnace, vacuumize (0.1Pa) and fill with argon gas, the furnace The pressure is 0.5 MPa, smelting at 1800K for 6 hours to obtain a metal smelting solution; pour the metal smelting solution into a water-cooled ingot mold and cool to obtain an alloy ingot. The alloy ingot is placed in a horizontal heat treatment furnace, vacuumed (0.1Pa), filled with protective gas argon, the pressure in the furnace is 1MPa, annealed at 1500K for 10h, and jet crushed to obtain rare earth-magnesium- Nickel-based multiphase superlattice hydrogen storage alloy. XRD test showed that AB 5 Phase accounted for 18.5%, A 2 B 7 Phase accounted for 79.8%, the rest with AB 3 、A 5 B 19 , The B-side free phase exists in the form of an impurity phase.

Embodiment 4

[0025] According to the structural formula La 0.50 Ce 0.10 SM 0.10 Mg 0.35 Ni 3.70 Al 0.40 co 0.50 mn 0.40 Sr 0.05 Weigh the metal raw materials La, Ce, Sm, Mg, Ni, Al, Co, Mn, Sr in the molar ratio, put them all in the crucible of the induction melting furnace, vacuumize (0.1Pa) and fill it with argon gas, the furnace The pressure is 0.001MPa, smelting at 2000K for 2 hours to obtain a metal smelting solution; pour the metal smelting solution into a water-cooled ingot mold and cool to obtain an alloy ingot. Place the alloy ingot in a horizontal heat treatment furnace, vacuumize (0.1Pa) and fill it with protective gas argon, the pressure in the furnace is 0.005MPa, anneal at 1800K for 5h, and jet crush to obtain rare earth-magnesium for nickel-metal hydride batteries - Nickel-based multiphase superlattice hydrogen storage alloy. XRD test showed that AB 5 Phase accounted for 27.0%, A 2 B 7 Phase accounted for 71.8%, the rest with AB 3 、A 5 B 19 , The B-side free p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com