Thermal Field Structure of Polycrystalline Ingot Furnace for Large Size Silicon Ingot

A polycrystalline ingot, large-size technology, applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problems of unfavorable impurity removal, influence on the overall quality of the crystal, and small charging volume, so as to improve production Effects of productivity, reduction of crystal defects, and expansion of internal dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

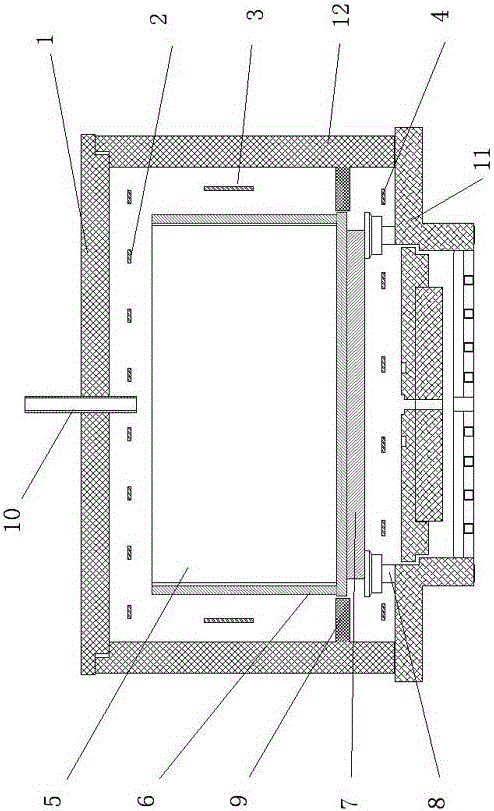

[0020] Refer to attached figure 1 , a heat field structure of a polycrystalline ingot casting furnace for large-sized silicon ingots, including a heat insulation cage surrounded by an upper insulation board 1, a lower insulation board 11 and a side insulation board 12. The size of the insulation cage is designed according to the size of the crucible. It can be made into a large-scale structure, so that the size of the thermal field can be enlarged, and a large crucible can be used to charge the material to increase the weight of the polysilicon material. The size of the side insulation board 12 inner wall of the large-size thermal insulation cage is 1340mm.

[0021] The upper insulation board 1 is provided with an air intake pipe 10 extending into the heat insulation cage. The upper air intake mode can improve the gas circulation in the furnace, facilitate the removal of impurities, and improve the crystal quality.

[0022] A directional solidification block 7 is arranged in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com