Integrated supporting system and tunnel boring machine with same

A support system and slewing system technology, applied in tunnels, tunnel linings, bolt installation, etc., can solve the problems of not being able to meet the requirements of tunnel construction support lining, high manufacturing and maintenance costs, and large space occupation, and achieve simple structure and Compactness, reduced manufacturing and maintenance costs, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

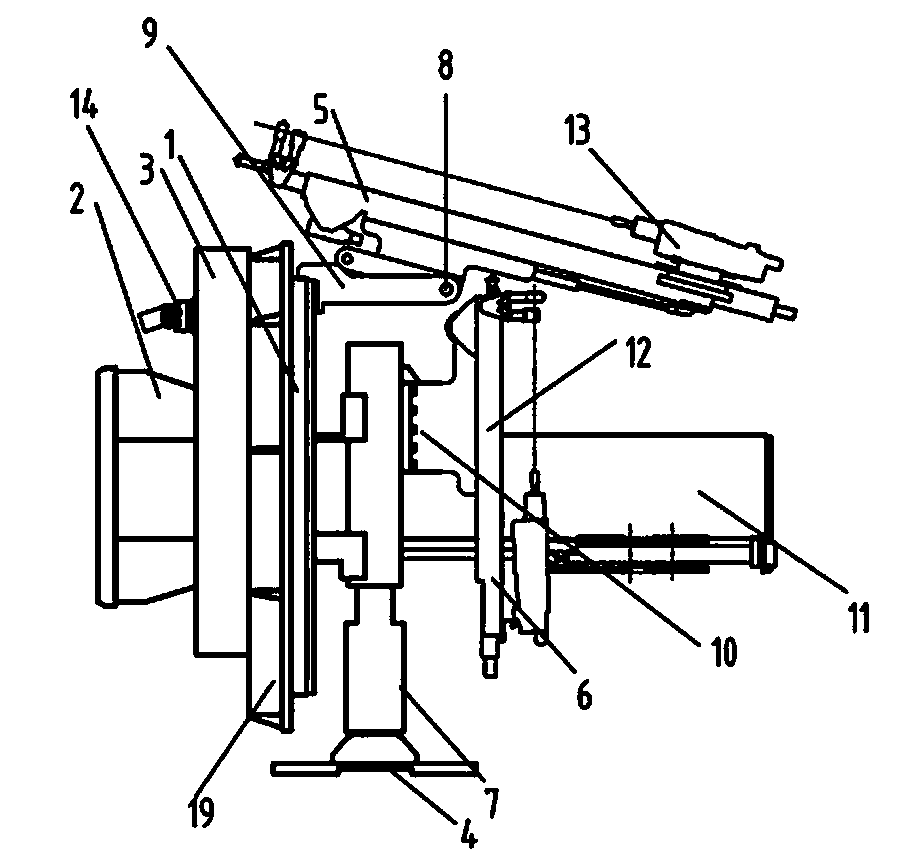

[0025] Such as figure 1 As shown, the integrated support system for tunnel boring machine (TBM) of the present invention includes: a segment / invert block assembly system 1, an advanced drilling / reinforcement system 5, a bolter system 6, a total rotary system 3, and a total translation support System 2.

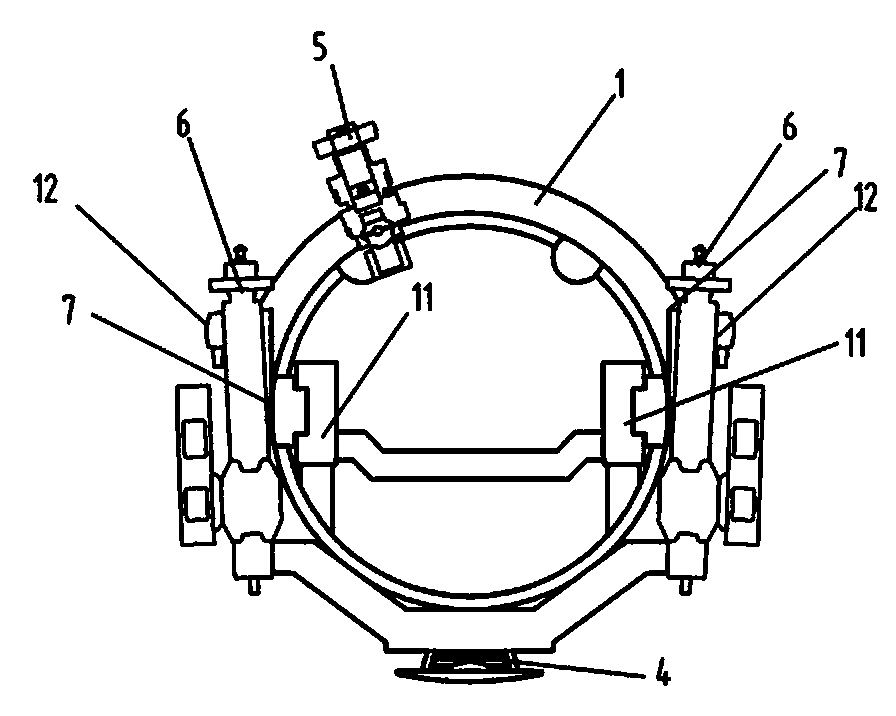

[0026] Among them, the segment / invert block assembly system 1 mainly includes: a segment clamping device 4, a lifting mechanism 7, and the like.

[0027] The advance drilling / reinforcement system 5 mainly includes: a set of easily detachable advance drilling rig 13, the advance drilling rig system mounting support 9 and its hydraulic and electrical control system.

[0028] The rock bolt system 6 mainly includes: two sets of easily detachable rock bolt 12, the rock bolt system mounting support 10 and its hydraulic and electrical control system.

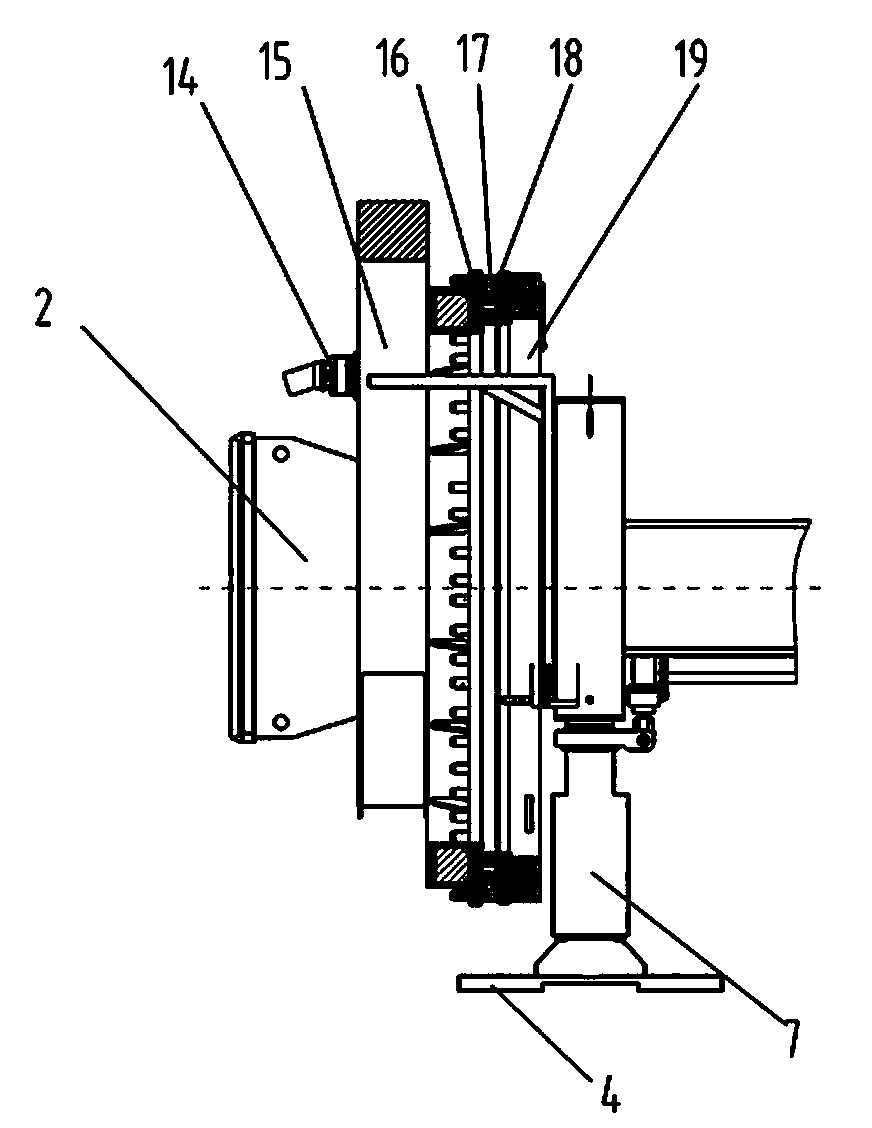

[0029] The slewing system 3 mainly includes: a moving support 15, a rotating support 19, 2 hydraulic motors and a reducer 14, a pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com