Machining method for high-voltage capacitive dry-type bushing

A dry-type bushing and high-voltage capacitor technology, applied in the direction of circuits, electrical components, insulators, etc., can solve the problems of high production cost, bushing failure, and many layers of capacitor electrodes, and achieve small structural size and radial field strength. The effect of uniform and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

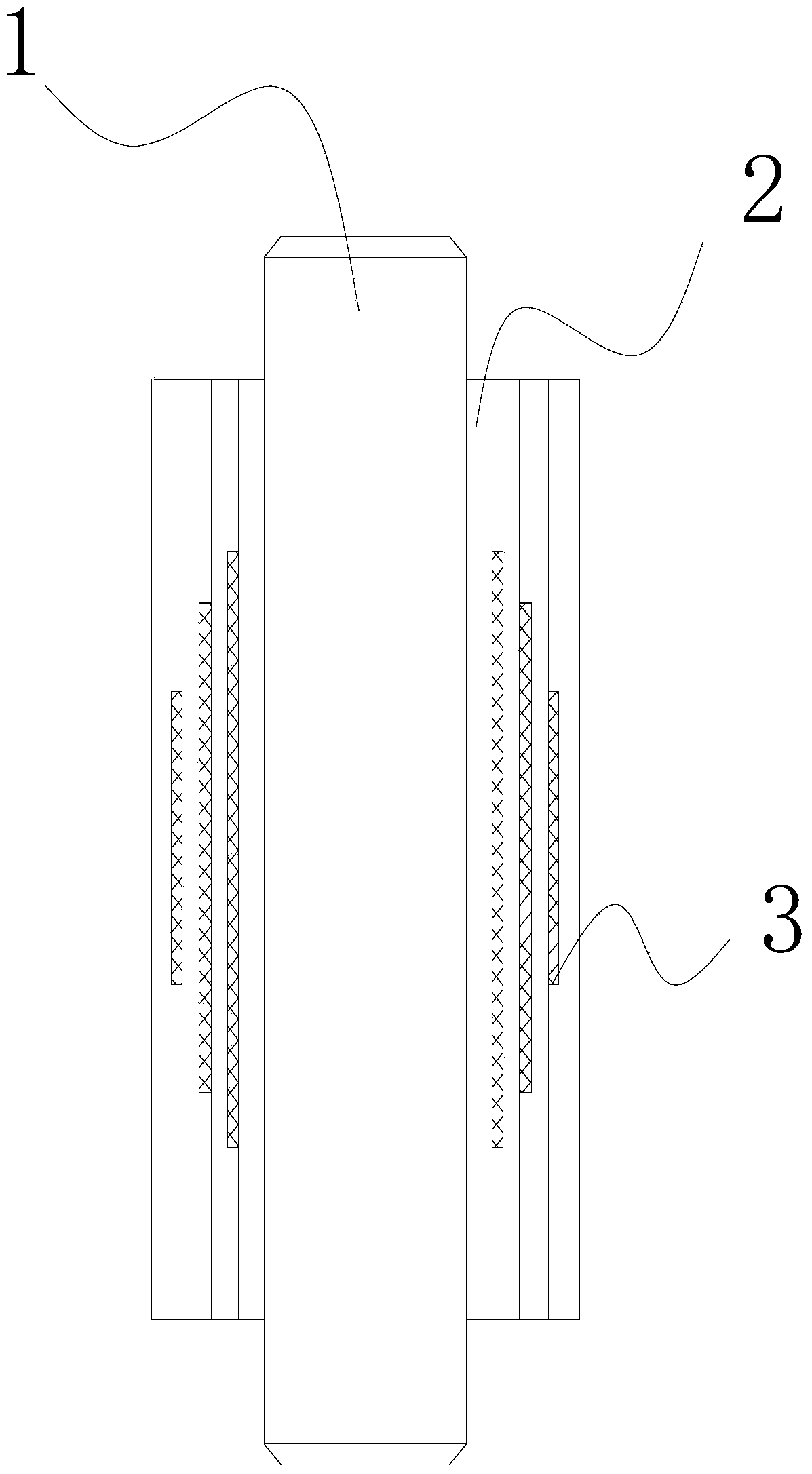

[0034] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0035] The processing method of the high-voltage capacitive dry bushing comprises the following steps:

[0036] 1] core rolling

[0037] 1.1] Determine the diameter of the conductive rod according to the current-carrying method and sandblast the surface of the conductive rod and coat the coupling agent; for example: determine the conductive rod with a current carrying capacity of 1250 amperes, its diameter is 65mm, and the current-carrying method is direct current-carrying. The compressed air sandblasting process is used to perform sandblasting on the surface of the conductive rod. The sand can be 80-100 mesh sand grains made of corundum. After the sandblasting is completed, it needs to be cleaned and dried. Coupling agent twice, the coupling agent can choose KH550, KH560, the performance of KH550 is to improve the bonding activity of epoxy resin and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com