Control circuit of step-down dcdc converter

A control circuit, logic control circuit technology, applied to the direction of conversion equipment without intermediate conversion to AC, can solve the problems of reducing the current change rate, increasing the volume, output voltage overshoot or large drop, etc., to increase the switching frequency , to avoid adverse effects, to avoid the effect of audio noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

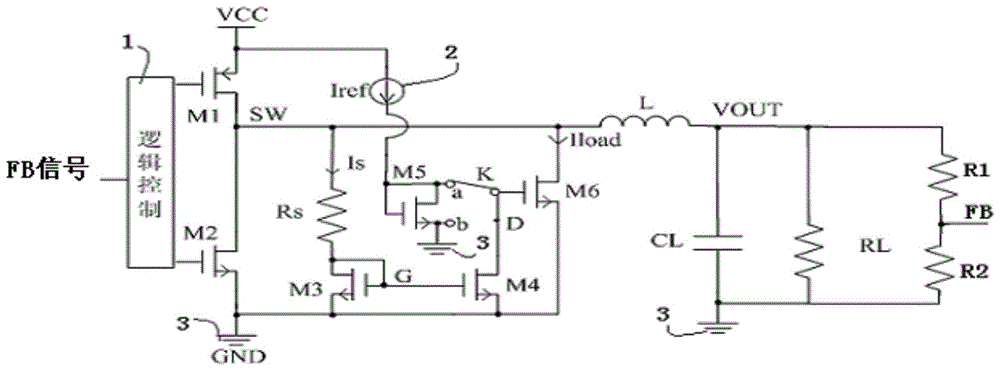

[0017] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0018] figure 1 It is a structural schematic diagram of the control circuit of the step-down DC-DC converter implementing the present invention. like figure 1 As shown, the control circuit of the step-down DCDC converter includes a first PMOS transistor M1 and a second NMOS transistor M2, the gate of the first PMOS transistor M1 and the gate of the second NMOS transistor M2 are respectively connected with logic control The circuit 1 is connected, the drain of the first PMOS transistor M1 and the drain of the second NMOS transistor M2 are connected to each other to form the first node, that is, the switch node SW, and the source of the second NMOS transistor M2 is connected to the ground terminal 3 The source of the first PMOS transistor M1 is connected to the input voltage terminal VCC; the switch node SW is connected to the output voltage terminal VOUT through an inductor, betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com