Cobalt/graphene composite nano wave-absorbing material and preparation method thereof

A composite technology of nano-absorbing materials and graphene, which is applied in the field of absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

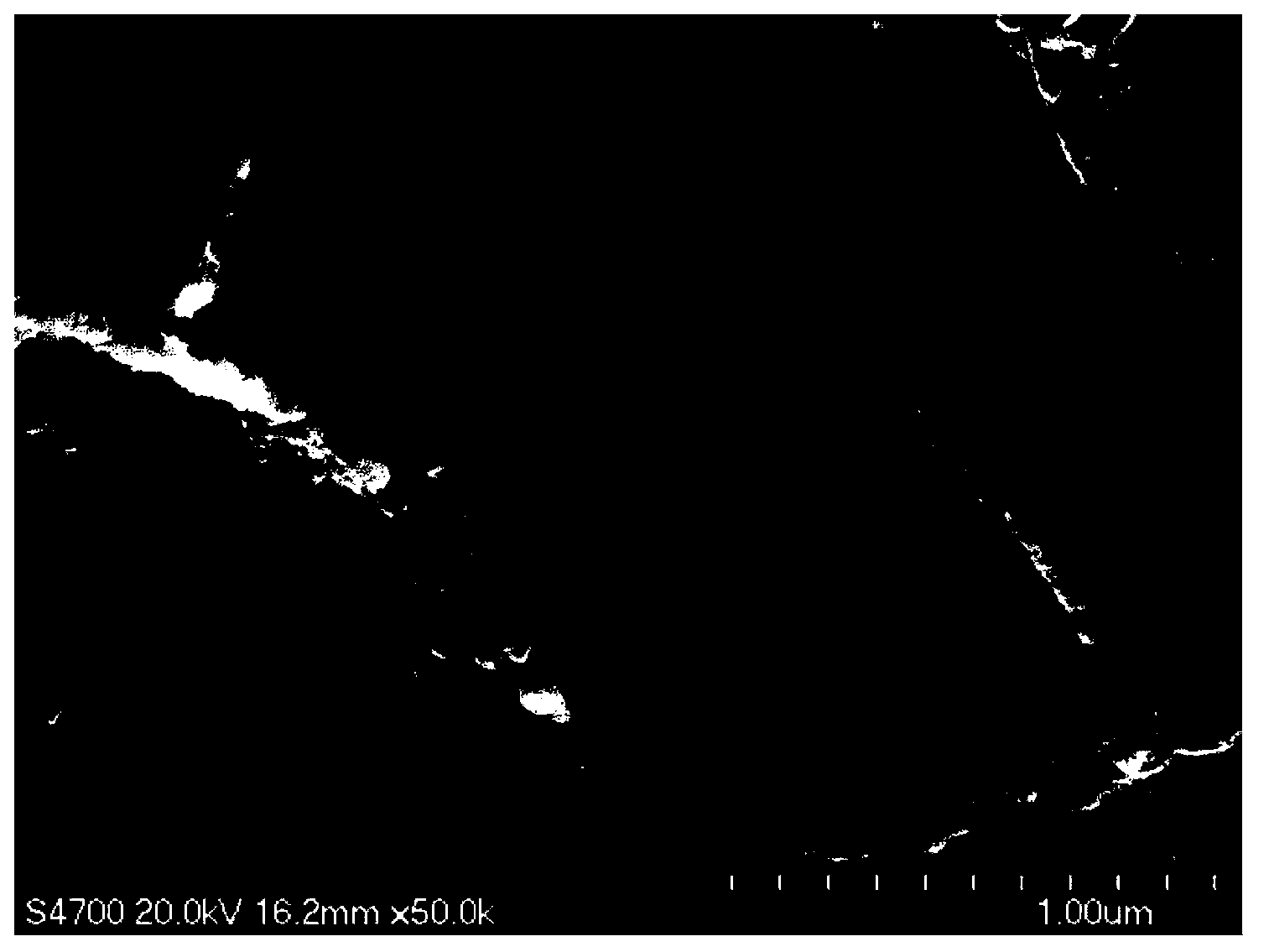

Image

Examples

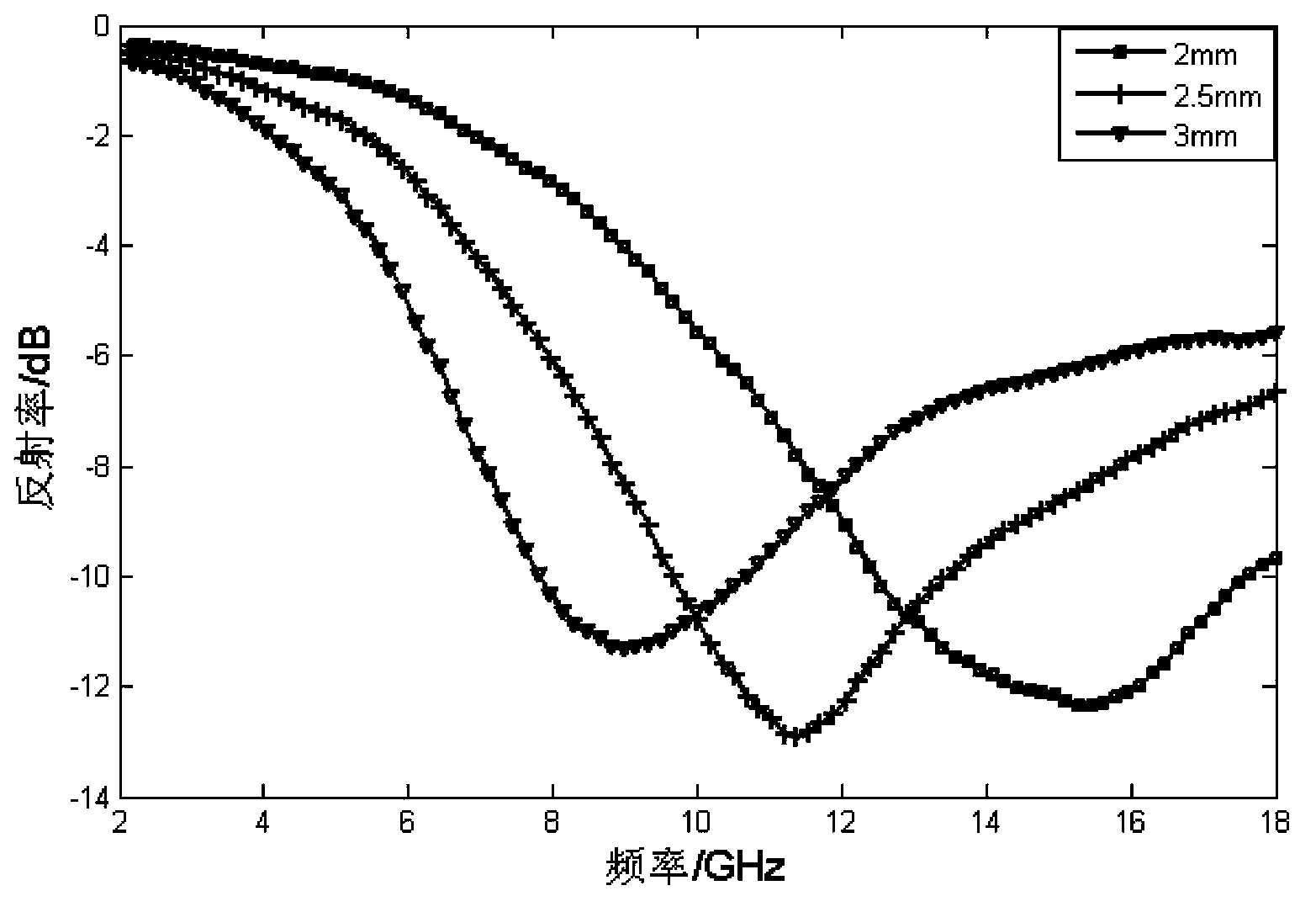

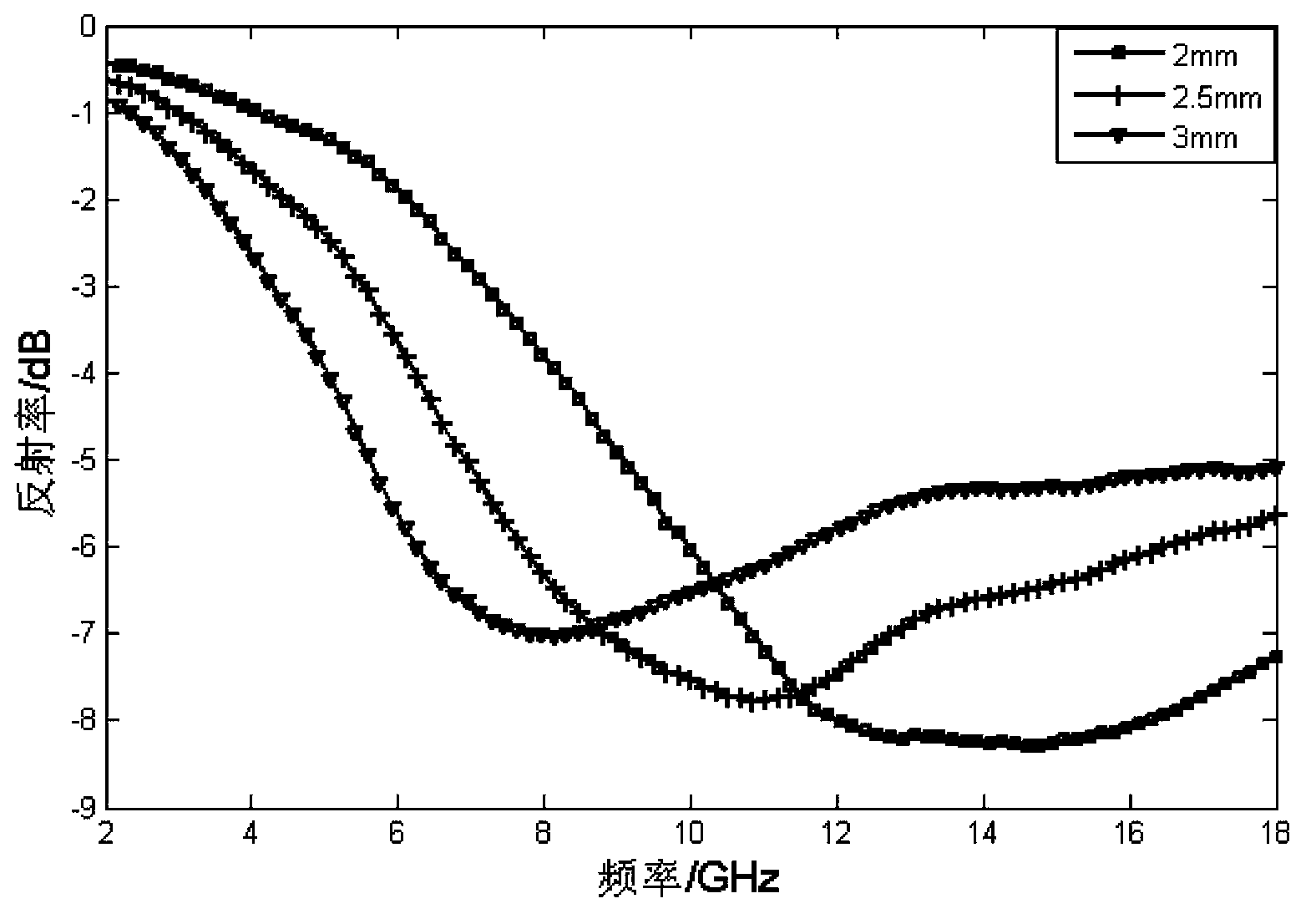

Embodiment 1

[0036] Step 1: Preparation of Graphene Oxide

[0037] Take 3g of graphite and put it into a three-necked flask, add 360ml of 98% concentrated sulfuric acid and 40ml of 85% concentrated phosphoric acid, and stir at room temperature for 24 hours. Transfer the three-neck flask to an ice-water bath, and after the temperature drops to 4°C, slowly add 18g of potassium permanganate to control the temperature below 20°C. After stirring evenly, the temperature was raised to 50° C. for 12 hours to stop the reaction. After the product is cooled, pour it into 400ml of ice, and add 3ml of hydrogen peroxide with a mass fraction of 30%. After the product is cooled, it is centrifuged and washed with 10% hydrochloric acid and water respectively to obtain graphite oxide. Ultrasonic stripping of graphite oxide for 2 hours, high-speed centrifugation, taking the upper layer solution, drying and grinding to obtain graphene oxide powder.

[0038] Step 2: Reduction of Graphene Oxide

[0039] Take...

Embodiment 2

[0049] Step 1: Preparation of Graphene Oxide

[0050] Take 3g of graphite and put it into a three-necked flask, add 360ml of 98% concentrated sulfuric acid and 40ml of 85% concentrated phosphoric acid, and stir at room temperature for 24 hours. Transfer the three-neck flask to an ice-water bath, and after the temperature drops to 4°C, slowly add 18g of potassium permanganate to control the temperature below 20°C. After stirring evenly, the temperature was raised to 50° C. for 12 hours to stop the reaction. After the product is cooled, pour it into 400ml of ice, and add 3ml of hydrogen peroxide with a mass fraction of 30%. After the product is cooled, it is centrifuged and washed with hydrochloric acid and water with a volume ratio of 10%, respectively, and finally graphite oxide is obtained. Ultrasonic stripping of graphite oxide for 2 hours, high-speed centrifugation, taking the upper layer solution, drying and grinding to obtain graphene oxide powder.

[0051] Step 2: Red...

Embodiment 3

[0060] Step 1: Preparation of Graphene Oxide

[0061] Take 3g of graphite and put it into a three-necked flask, add 360ml of concentrated sulfuric acid with a concentration of 98%, and 40ml of concentrated phosphoric acid with a concentration of 85%, and stir at room temperature for 24 hours. The three-neck flask was transferred to an ice-water bath, and after the temperature dropped to 4°C, 18 g of potassium permanganate was slowly added to control the temperature to 20°C. After stirring evenly, the temperature was raised to 50° C. for 12 hours to stop the reaction. After the product is cooled, pour it into 400ml of ice, and add 3ml of hydrogen peroxide with a mass fraction of 30%. After the product is cooled, it is centrifuged and washed with 10% hydrochloric acid and water respectively to obtain graphite oxide. Ultrasonic stripping of graphite oxide for 2 hours, high-speed centrifugation, taking the upper layer solution, drying and grinding to obtain graphene oxide powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com