A kind of preparation method of layered titanium-aluminum composite plate

A composite plate and composite slab technology, which is applied in the field of preparation of layered titanium-aluminum composite plates, can solve the problems of limited performance and application fields, insufficient bonding strength, etc., and achieve the effects of reducing costs, improving production efficiency, and avoiding interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

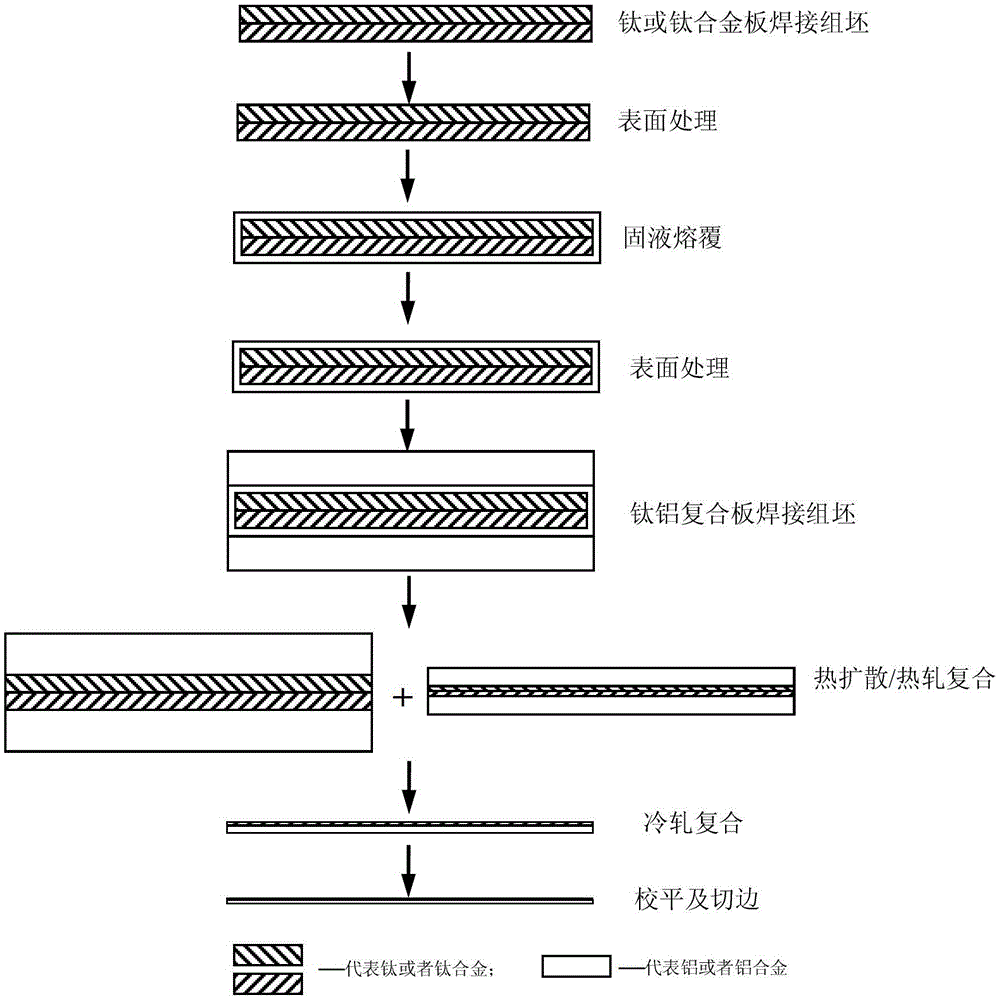

[0027] according to figure 1 According to the flow chart, the preparation process of the layered TA1 titanium / 2024 aluminum composite plate with a thickness of 1.5mm is as follows:

[0028] (1) TA1 titanium plate welding assembly: two TA1 titanium alloy plates with a thickness of 1mm and a size of 870×870mm are closely attached, and their edges are welded together;

[0029] (2) Surface treatment: Clean and shot blast the outer surface of the welded TA1 titanium slab to remove the oxide layer;

[0030] (3) Solid-liquid cladding: immerse the surface-treated TA1 titanium slab into molten 2024 aluminum at a temperature of 650-700°C for 10-20 minutes, so that the surface of the TA1 titanium plate is clad with a thickness of 0.5mm The 2024 aluminum alloy layer was obtained to obtain a TA1 titanium / 2024 aluminum composite plate blank.

[0031] (4) Surface treatment: The upper and lower surfaces of the TA1 titanium / 2024 aluminum composite plate blank after solid-liquid cladding are ...

Embodiment 2

[0037] according to figure 1 According to the flow chart, the preparation process of the layered TA1 titanium / 2024 aluminum composite plate with a thickness of 1.5mm is as follows:

[0038] For the layered TA1 titanium / 2024 aluminum composite plate described in the specific embodiment 1, it is also possible to use another kind of specification and thickness material to prepare:

[0039] (1) TA1 titanium plate welding assembly: make two TA1 titanium plates with a thickness of 2mm and a size of 870×870mm fit closely, and weld their edges together;

[0040] (2) Surface treatment: Clean and shot blast the surface of the welded TA1 titanium slab to remove the oxide layer;

[0041] (3) Solid-liquid cladding: immerse the surface-treated TA1 titanium slab in molten 2024 aluminum at a temperature of 650-700°C for 20-30 minutes, so that the surface of the TA1 titanium plate is clad with a layer of 1mm thick 2024 aluminum alloy layer to obtain TA1 titanium / 2024 aluminum composite plate...

Embodiment 3

[0048] according to figure 1 According to the flow chart, the preparation process of the layered TA1 titanium / 1050 aluminum composite plate with a thickness of 1.5mm is as follows:

[0049] (1) TA1 titanium plate welding assembly: make two TA1 titanium plates with a thickness of 1mm and a size of 870×870mm fit closely, and weld their edges together;

[0050] (2) Surface treatment: Clean and shot blast the outer surface of the welded TA1 titanium slab to remove the oxide layer;

[0051] (3) Solid-liquid cladding: immerse the surface-treated TA1 titanium alloy plate in molten 1050 aluminum liquid at a temperature of 700-750°C for 10-20 minutes, so that the surface of the TA1 titanium plate is clad with a layer of 0.5mm thick 1050 aluminum layer to obtain TA1 titanium / 1050 aluminum composite plate blank;

[0052] (4) Surface treatment: The upper and lower surfaces of the solid-liquid cladding TA1 titanium / 1050 aluminum composite plate blank are cleaned, shot blasted and polishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com