Metal doped mesoporous silicon-based molecular sieve nanosphere and preparation method thereof

A technology of metal doping and molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of easy industrial production, safe operation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

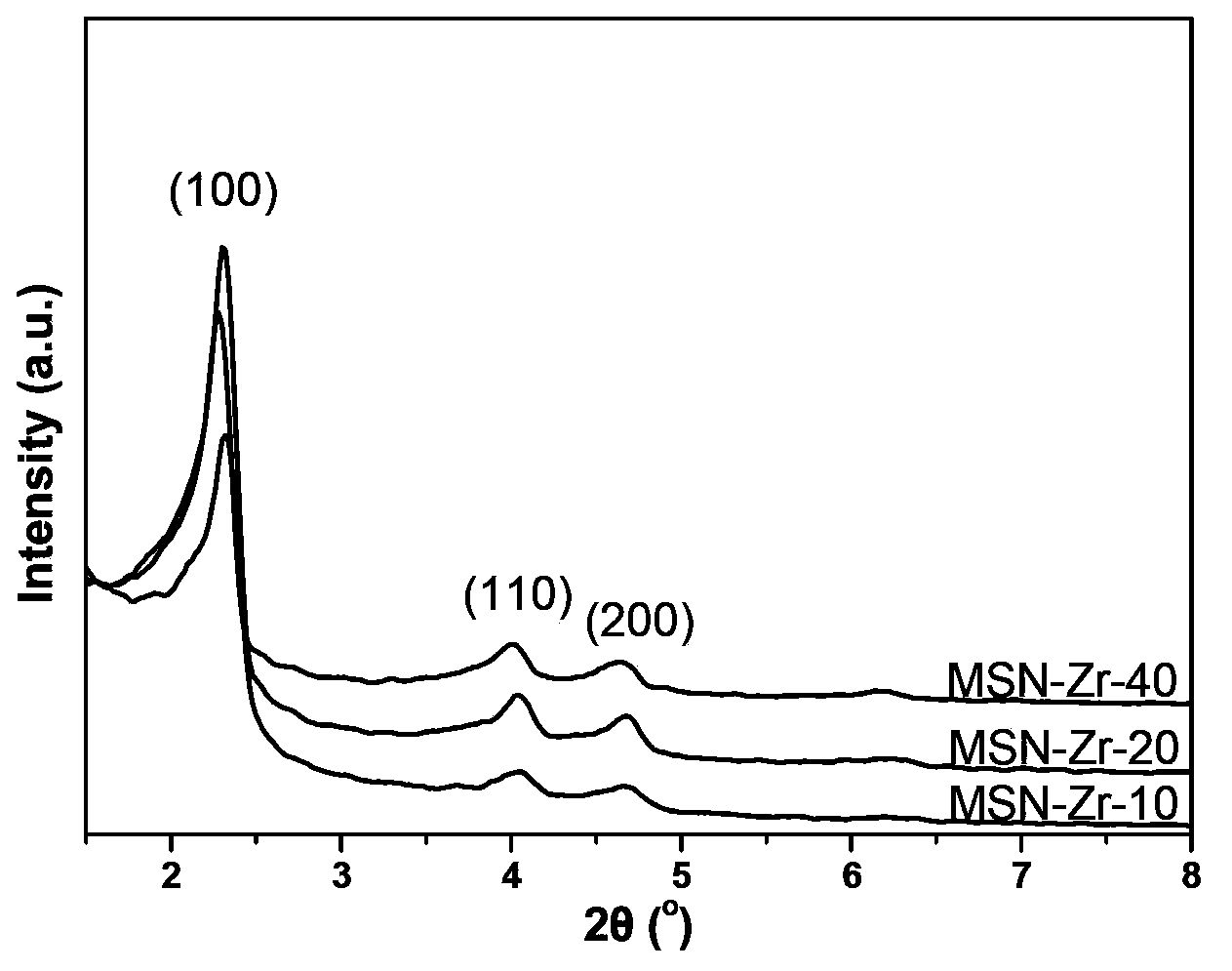

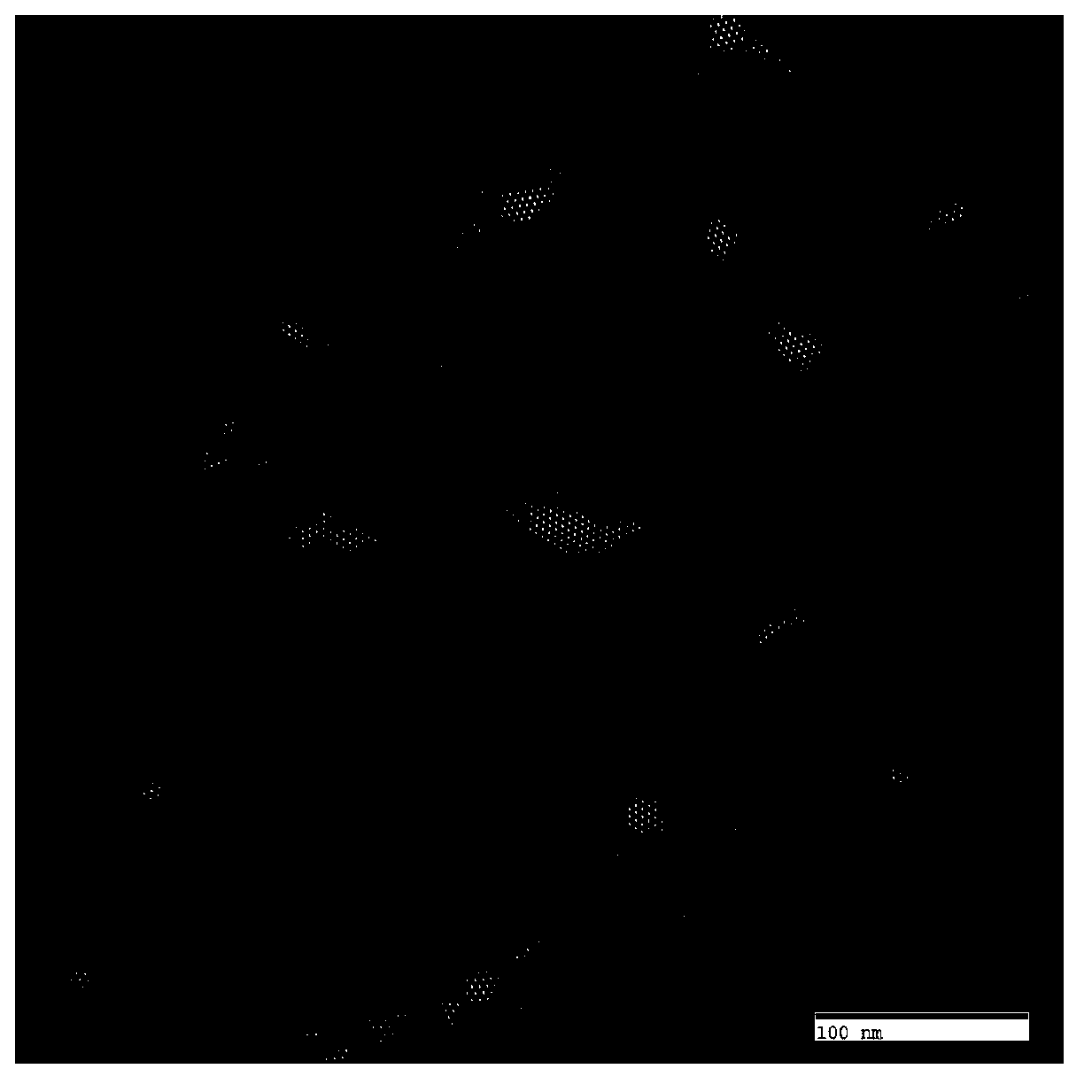

[0024] Example 1 Synthesis of zirconium-doped mesoporous silicon-based molecular sieve nanospheres

[0025]Ethyl orthosilicate is used as the silicon source, and zirconium n-propoxide is used as the zirconium source. Dilute 12g of concentrated ammonia water (25wt%) to 300g (pH=11.4) with deionized water, add 0.58g of CTAB, stir and dissolve in a 50°C water bath. Prepare ethanol solution A of ethyl orthosilicate with different concentrations and ethanol mixed solution B of ethyl orthosilicate and zirconium n-propoxide: the concentration of (Si) in A is 0.2mol L -1 , the concentration of (Si) in B is 1.0mol·L -1 (At the same time, B prepared three groups respectively, so that Zr / Si=0.025, 0.05, 0.1). Quickly add 5mL of solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add 5mL of solution B dropwise, continue stirring for 1 hour, stop stirring, and stand in a water bath at 50°C for 20 hours. The reaction mixture was separated...

Embodiment 2

[0026] Example 2 Effect of different molar ratios of CTAB on the synthesis of zirconium-doped mesoporous silicon-based molecular sieve nanospheres

[0027] Ethyl orthosilicate is used as the silicon source, and zirconium n-propoxide is used as the zirconium source. Dilute 12g of concentrated ammonia water (25wt%) to 300g (pH=11.4) with deionized water, add 0.50g, 0.58g, 0.70g of CTAB respectively, stir and dissolve in a 50°C water bath. Prepare ethanol solution A of ethyl orthosilicate with different concentrations and ethanol mixed solution B of ethyl orthosilicate and zirconium n-propoxide: the concentration of (Si) in A is 0.2mol L -1 , the concentration of (Si) in B is 1.0mol·L -1 ; Zr / Si=0.05 in B. Quickly add 5mL of solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add 5mL of solution B dropwise, continue stirring for 1 hour, stop stirring, and stand in a water bath at 50°C for 20 hours. The reaction mixture was cent...

Embodiment 3

[0028] Example 3 Different templates are used to synthesize titanium-doped mesoporous silicon-based molecular sieve nanospheres

[0029] Ethyl orthosilicate is used as the silicon source, and titanium tetrachloride is used as the titanium source. Dilute 12g of concentrated ammonia water (25wt%) to 300g (pH=11.4) with deionized water, add 0.42g of DTAC, 0.58g of CTAB, and 0.55g of STAC, and stir to dissolve in a 50°C water bath. Prepare ethanol solutions A of different concentrations of ethyl orthosilicate and ethanol mixed solution B of ethyl orthosilicate and titanium tetrachloride: the concentration of (Si) in A is 0.2mol L -1 , the concentration of (Si) in B is 1.0mol·L -1 ; Ti / Si=0.05 in B. Quickly add 5mL of solution A to the above mixture under stirring, seal the reactor, stir for 5 hours, open the reactor, add 5mL of solution B dropwise, continue stirring for 1 hour, stop stirring, and stand in a water bath at 50°C for 20 hours. The reaction mixture was separated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com