Crude benzene hydrorefining catalyst and preparation method thereof

A technology for hydrorefining and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. The problems of complex composition and reduced benzene recovery rate can achieve the effect of enhancing anti-poisoning performance, improving the use of a smaller temperature range and improving the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

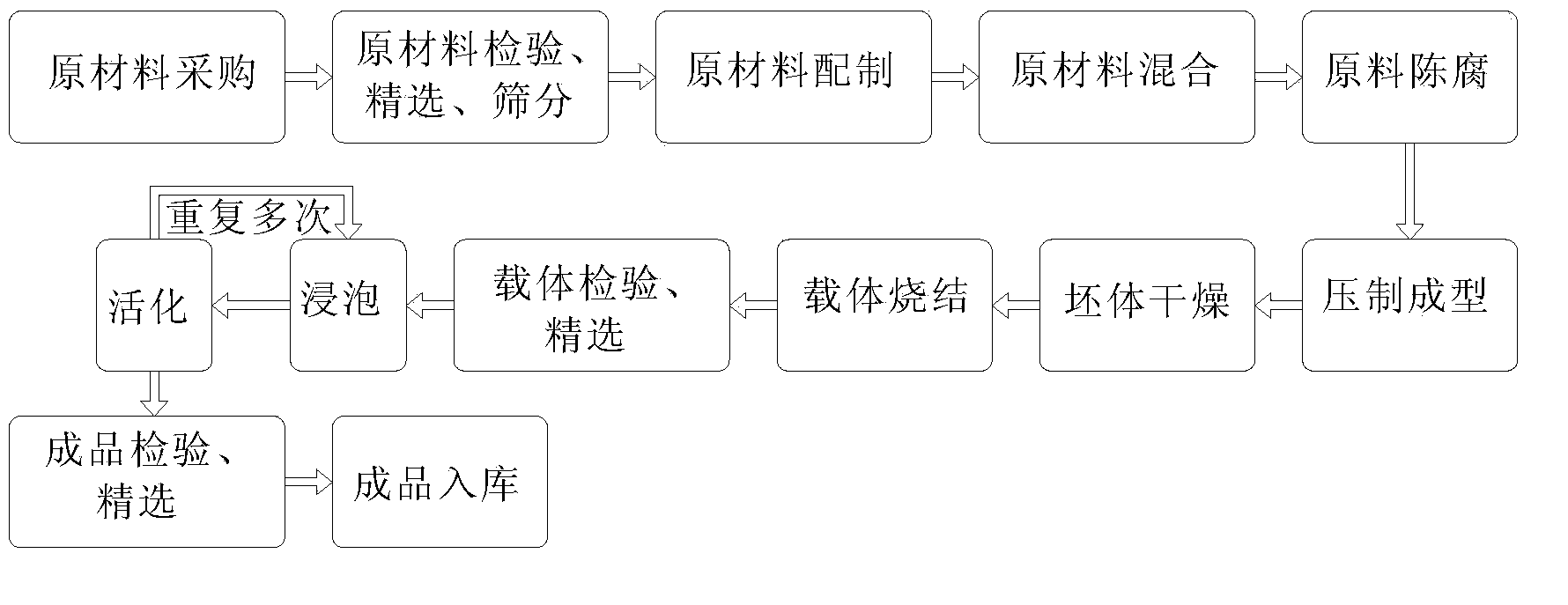

Method used

Image

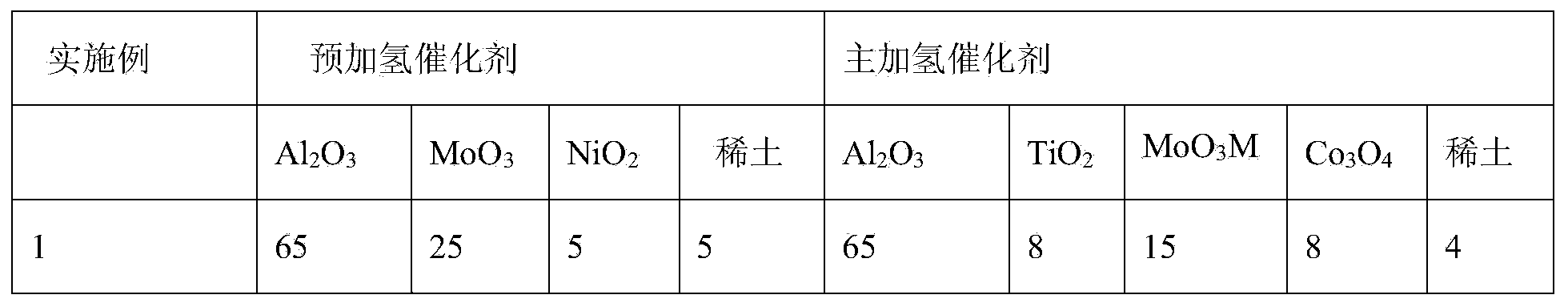

Examples

Embodiment

[0029] (1) Aluminum oxide, titanium oxide, and rare earth raw materials are screened and classified through vibrating screens to remove large particles;

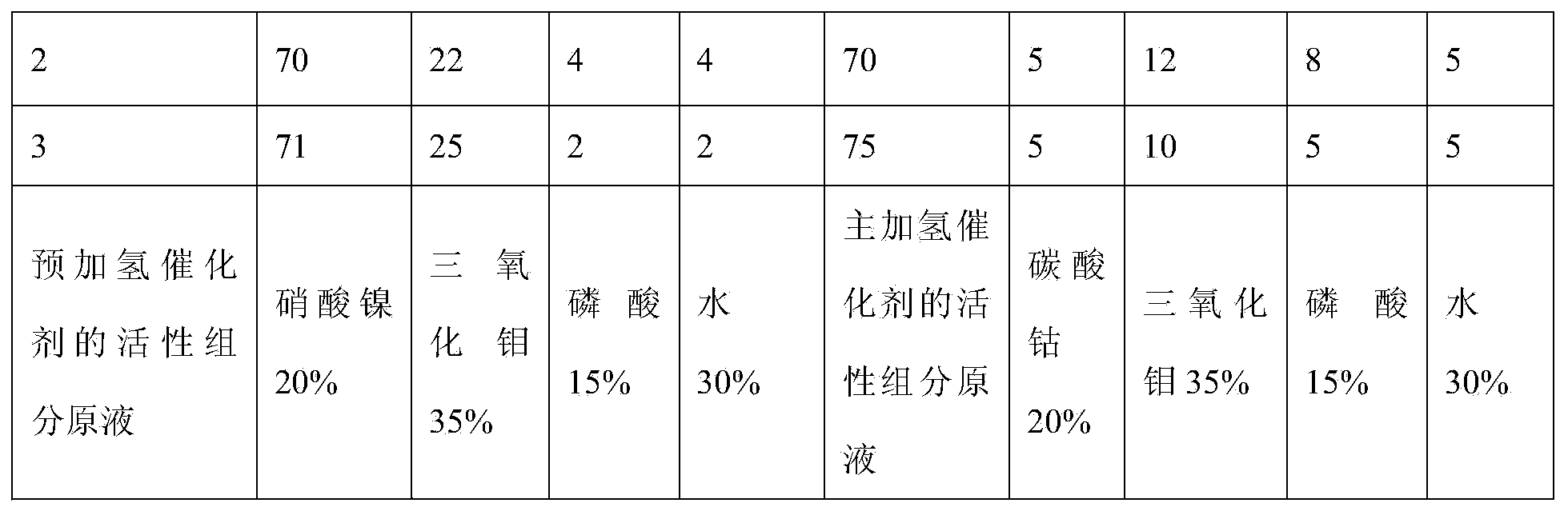

[0030] (2) After preparing the raw materials according to the formula ratio, adding the alumina and rare earth in the prehydrogenation catalyst to the nitric acid solution with a concentration of 10% to 20% by mass, the alumina and rare earth in the prehydrogenation catalyst are at a mass percent concentration The proportion in the nitric acid solution of 10-20% is 1-500g / ml; the aluminum oxide, titanium oxide and rare earth in the main hydrogenation catalyst are added to the nitric acid solution with a mass percentage concentration of 10-20%, and the main hydrogenation catalyst The ratio of aluminum oxide and rare earth in the nitric acid solution with a concentration of 10-20% by mass is 1-500g / ml; 15 to 20 hours to make its performance stable before use;

[0031] (3) In step (2), the old pre- and main hydrogenation catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com