Technology of extracting triacontanol from natural beeswax by microwave and solid superalkali catalysis

A solid super alkali and natural beeswax technology, applied in the chemical industry, can solve the problems of long time consumption, pollution of alkaline wastewater, organic matter discharge, etc., and achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

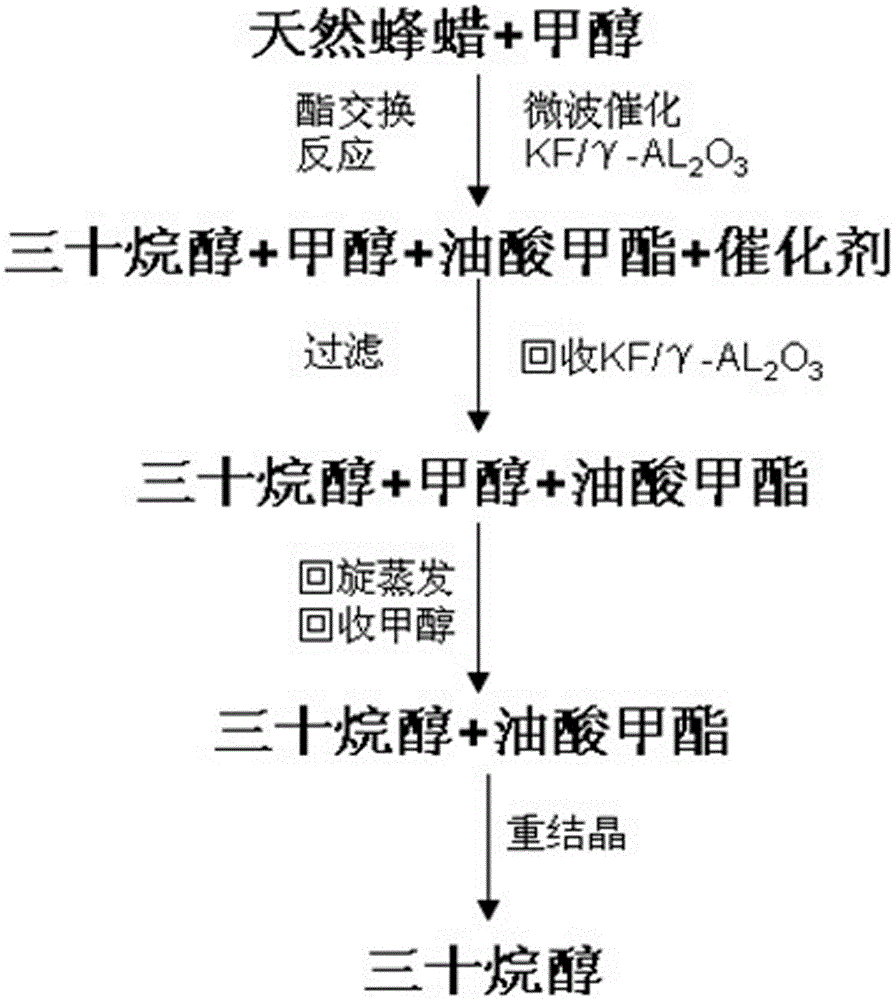

[0024] refer to figure 1 , the microwave of the present invention, solid superalkali catalyzed method extract the technology of triacontanol from natural beeswax, comprise the steps:

[0025] 1. Measure 25ml of methanol into a 100ml quartz round bottom flask, mix 0.5g of beeswax with 0.15g of catalyst KF / γ-Al 2 o 3 Add them together, and heat under reflux for 10 minutes under the condition of 200 to 300W microwave power.

[0026] 2. After the reaction, the mixed solution containing triacontanol, methyl oleate, methanol and catalyst is taken out from the round bottom flask, and the solid super base is recovered by filtration.

[0027] 3. The filtered mixture was distilled under reduced pressure with a rotary evaporator to recover methanol, and the set temperature was 50°C.

[0028] 4. The residue after recovering methanol is purified by recrystallization method with ethyl acetate as solvent, the yield is 50-60%, and the content of triacontanol is determined by gas chromatogr...

Embodiment 2

[0030] With reference to Example 1, the enlarged test of the process of extracting triacontanol from natural beeswax by microwave and solid super base catalysis method of the present invention comprises the following steps:

[0031] 1. Measure 12.5 liters of methanol in a microwave reactor container of 30 liters, mix 0.25 kg of beeswax with 0.075 kg of catalyst KF / γ-Al 2 o 3 Add them together, and heat under reflux for 30min under the condition of 6 to 9kw microwave power.

[0032] 2. After the reaction, the mixed solution containing triacontanol, methyl oleate, methanol and catalyst is discharged from the microwave reactor container, and the solid superbase is recovered by filtration.

[0033] 3. The filtered mixture is distilled under reduced pressure with a 50-liter concentrator to recover methanol, the vacuum pressure is controlled at 0.06 to 0.08Mp, and the temperature is controlled below 50°C.

[0034] 4. The residue after recovering methanol is purified by recrystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com