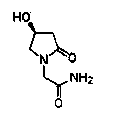

Synthetic method of oxiracetam

A synthetic method and intermediate technology, applied in the field of oxiracetam synthesis, can solve the problems of low condensation yield, many by-products, difficult industrialization, etc., and achieve the effect of cheap raw materials, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

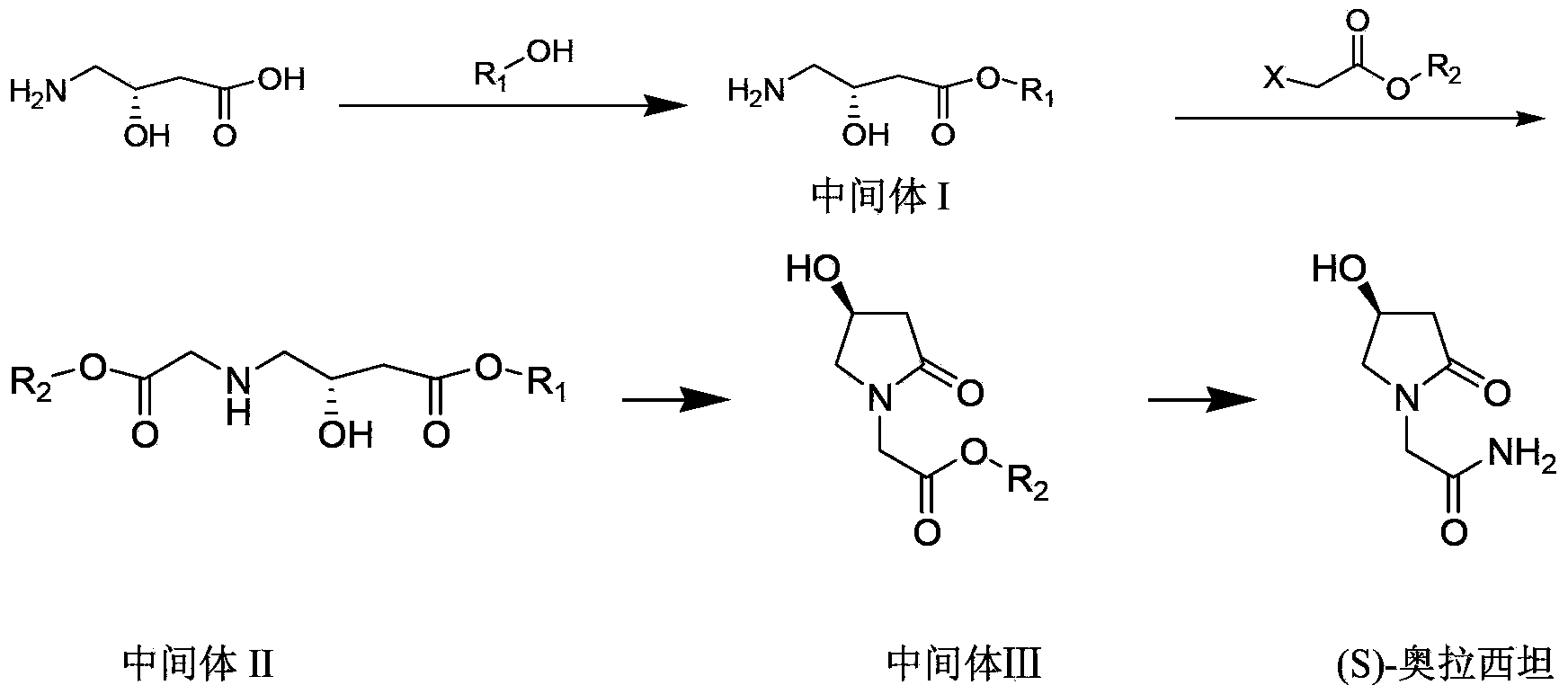

Method used

Image

Examples

Embodiment 1

[0055] A kind of synthetic method of (S)-oxiracetam, it carries out as follows,

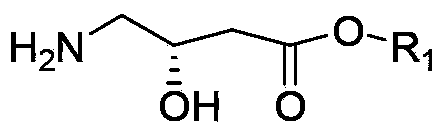

[0056] (l) Preparation of Intermediate I:

[0057] Take 50g of the raw material S-4-amino-3-hydroxybutyric acid, put it into a single-neck bottle, add 50ml of methanol, stir, cool in an ice-water bath, slowly add 150ml of concentrated hydrochloric acid, keep the temperature not exceeding 40°C, and the solid will first have a During the dissolution process, it precipitates again, and when the dripping speed is completed, the solid dissolves again, and finally forms a light yellow clear liquid. Stirring was continued for 3 hours, and the raw materials were basically completely reacted by pointing the board. The reaction was stopped, and the solvent was directly concentrated to remove a light yellow oil, which was solidified at a low temperature to obtain intermediate I. After nuclear magnetic detection, the intermediate I is: 1H-NMR (300MHz, D2O): δ2.76-2.67 (AB system, m, 2H,), 3.31-3.23 (AB syst...

Embodiment 2

[0070] 1, a kind of synthetic method of (S)-oxiracetam, follow the steps:

[0071] (1) Stir S-4-amino-3-hydroxybutyric acid and ethanol accounting for 18 times its weight, and react esterification reaction at 60 ° C for about 5 hours. The raw materials basically react completely, stop the reaction, and directly concentrate to remove the solvent. Solidify at low temperature to obtain intermediate I; at the same time, methanol, n-propanol, isopropanol, n-butanol, tert-butanol, cyclohexanol or cyclopentanol are used to prepare intermediate I as the above solvent, and finally tested by NMR , the prepared intermediate I is: 1H-NMR (300MHz, D2O): δ1.30 (m, 3H), 2.76-2.67 (AB system, m, 2H,), 3.31-3.23 (AB system, m, 2H), 4.12(m, 2H), 4.40(m, 1H), 4.70(bs, 3H).

[0072] (2) The intermediate I obtained from step (1) is stirred and cooled in ethanol that is 15 times by weight of S-4-amino-3-hydroxybutyric acid, and is added dropwise with n-butyl bromoacetate for condensation reaction ...

Embodiment 3--12

[0075] Embodiment 3--12: Compared with Embodiment 2, it is a further optimized embodiment of the present invention, according to the steps and parameters in Table 1 below, and the others are the same as Embodiment 1.

[0076] Table 1

[0077]

[0078]

[0079]

[0080] Through nuclear magnetic detection, the intermediate prepared in embodiment 3-12 and levoxiracetam are as shown in table 2:

[0081]

[0082]

[0083]

[0084]

[0085]

[0086]

[0087] The purity of the levoxiracetam obtained in the above examples 3-12 is measured by HPLC at 99.5-99.9%, and the calculated yield is 35-45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com