Fluorescent material and preparation method and application thereof

A technology of fluorescent materials and raw materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unstable physical and chemical properties of sulfide phosphors, quality damage of white light LED products, poor thermal stability, etc., and achieve low cost and light output Strong strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a method for preparing a fluorescent material, comprising the following steps:

[0043] (1) Use nitride or oxide and carbonate powder containing M, Si, R, L as raw materials, weigh the corresponding raw materials according to the stoichiometric ratio, and add flux in the proportion of 5%-20% of the total mass of the raw materials , grinding and mixing to obtain a raw material mixture.

[0044] (2) the mixture of step (1) gained is transferred in high temperature furnace, roasting in reducing atmosphere, roasting temperature is 1300-1800 ℃, roasting time is 3-10 hour, and described reducing atmosphere is hydrogen-nitrogen gas mixture, or Carbon monoxide, or toner.

[0045] (3) The product obtained in step (2) is the crude product of the compound described in claim 1, and through ball milling, cleaning, drying, and powder selection, the final product of the compound described in claim 1 is obtained.

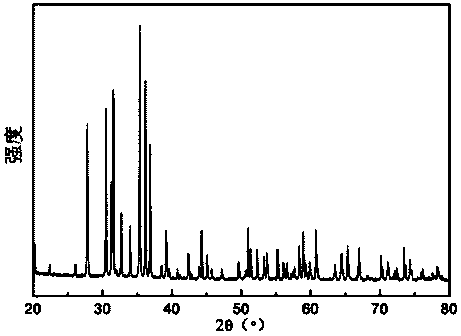

Embodiment 1~13

[0049] Under isolated air conditions, the use of Sr 3 N 2 (AR), Si 3 N 4(AR), Ti 3 N 4 (AR), Zr 3 N 4 (AR) and EuN (high purity) were used as raw materials, and the total mass of the raw materials was 50 g, wherein the molar ratios of the constituent elements of the aforementioned compounds in the raw materials were shown in Table 1. Re-incorporation of SrF 2 (AR) as a flux, the weight of the flux is 5% of the total weight of the raw materials, mixed evenly, transferred to a high-temperature furnace, in H 2 In a reducing atmosphere of a hydrogen-nitrogen mixed gas with a content of 4%, roast at 1500 ° C for 6 hours, take out the ball mill after natural cooling, wash with sodium hydroxide, and finally wash with deionized water, dry and select powder.

[0050] Table 1 Molar ratio of each constituent element in the raw materials of Examples 1-13

[0051]

Embodiment 14-20

[0061] Under isolated air conditions, the use of Ca 3 N 2 (AR), Si 3 N 4 (AR), Ti 3 N 4 (AR), Zr 3 N 4 (AR) and EuN (high purity) were used as raw materials, and the total mass of the raw materials was 50 g, wherein the molar ratios of the constituent elements of the aforementioned compounds in the raw materials were shown in Table 3. Re-incorporation of CaF 2 (AR) as a flux, its weight is 6% of the total weight of the raw materials, transferred to a high temperature furnace, in H 2 In a reducing atmosphere of a hydrogen-nitrogen mixed gas with a content of 4%, roast at 1650 ° C for 5 hours, take out the ball mill after natural cooling, wash with sodium hydroxide, and finally wash with deionized water, dry and select powder.

[0062] Table 3 The molar ratio of each constituent element in the raw materials of Examples 14-20

[0063]

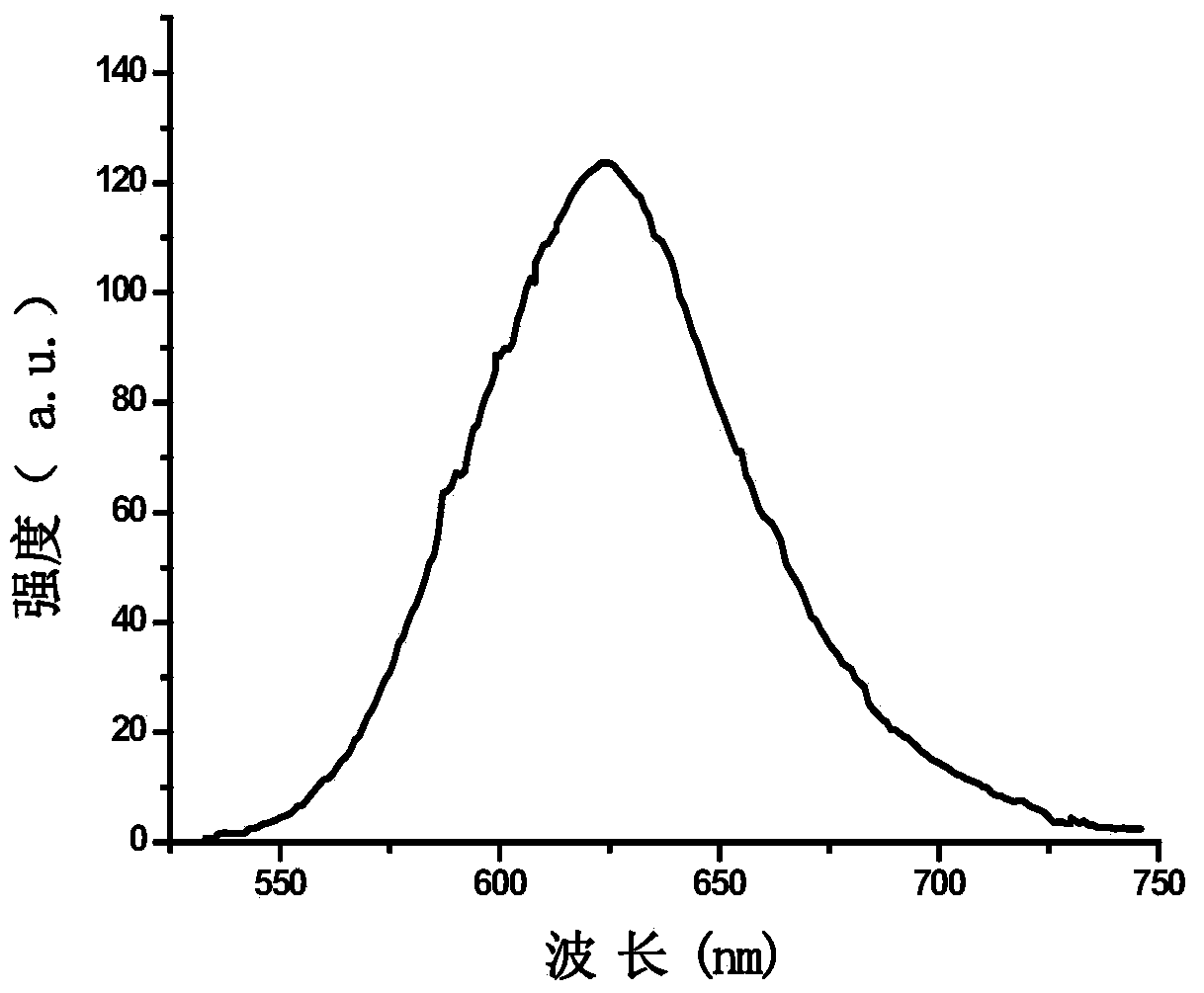

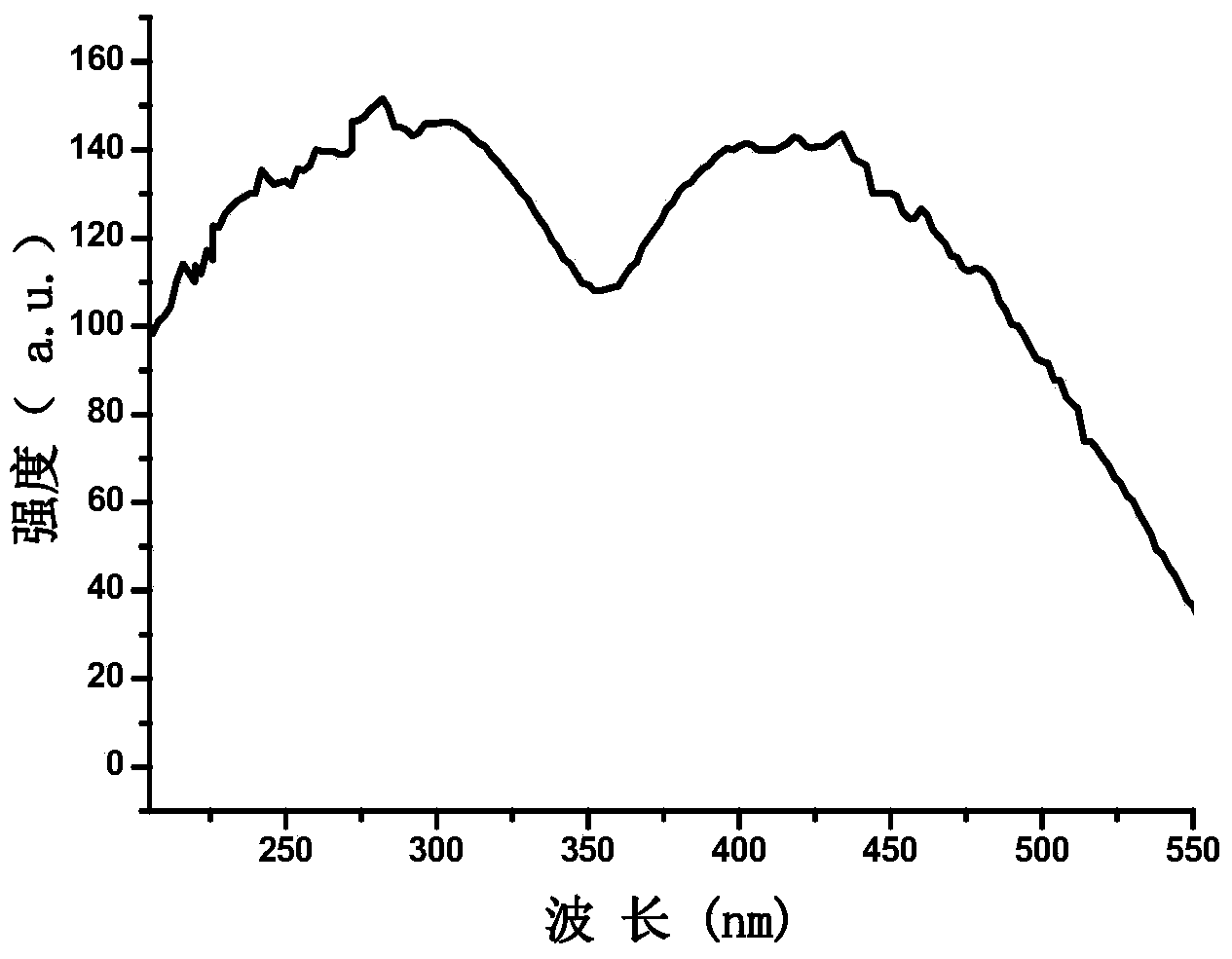

[0064] Table 4 shows the emission main peak wavelength (nm), relative luminescence intensity (%) and luminescence maintenance rate (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com