Method and system for monitoring sub-synchronous oscillation (SSO) and torsional vibration of shaft system of steam turbine generator unit

A turbo-generator set and sub-synchronous oscillation technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the accuracy limitation of the model simulation method, and the small amplitude current and voltage fluctuation of the generator cannot be accurately measured. Problems detected and unable to satisfy torsional vibration monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

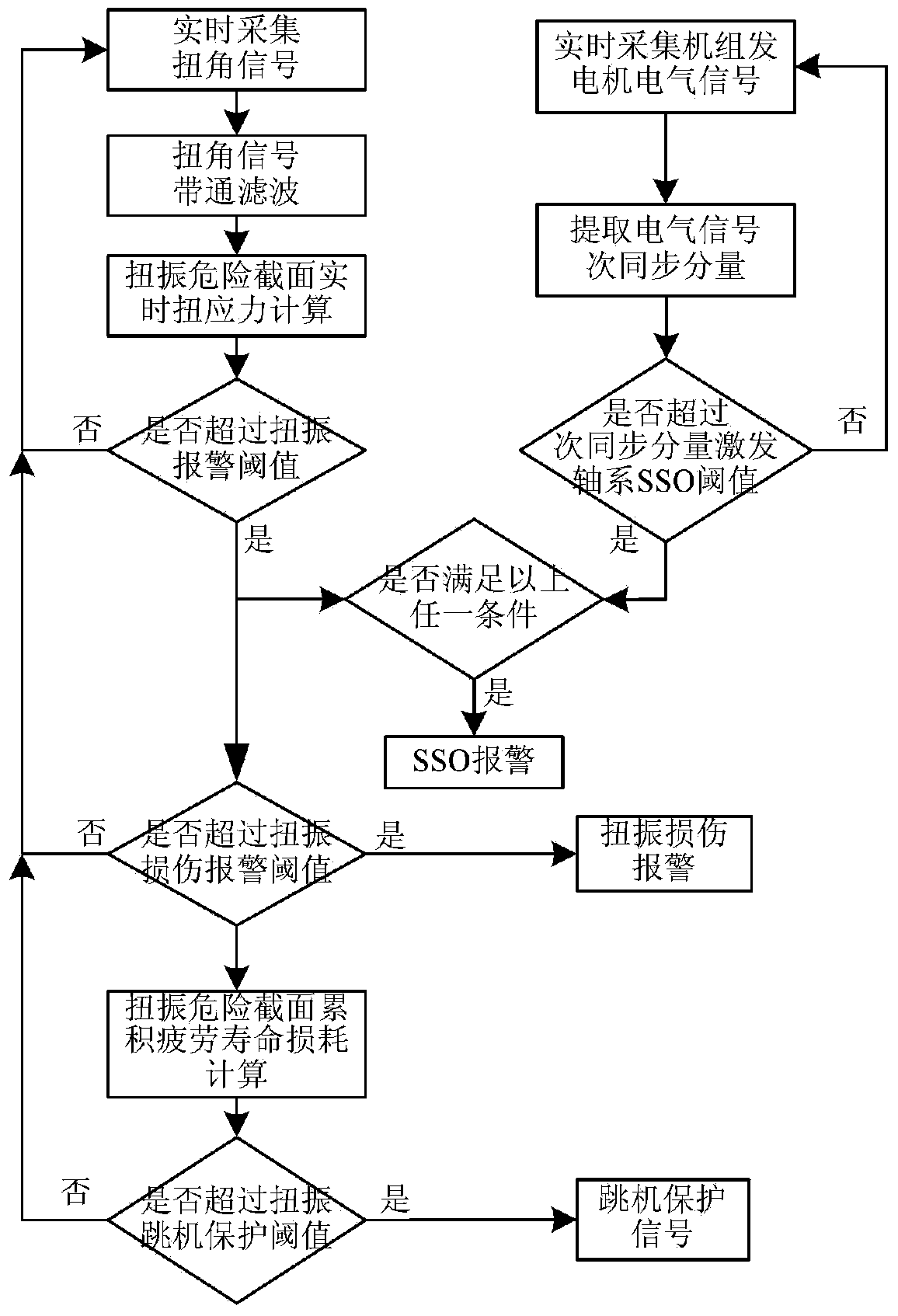

[0064] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. The present invention proposes a method for monitoring the torsional vibration of the shafting subsynchronous oscillation of the turbogenerator set, such as figure 1 shown, including:

[0065] Step A: Monitor the signal on the mechanical side of the shafting of the turbogenerator set,

[0066] A1: Real-time collection of shafting head and tail torsion angle signals of the unit;

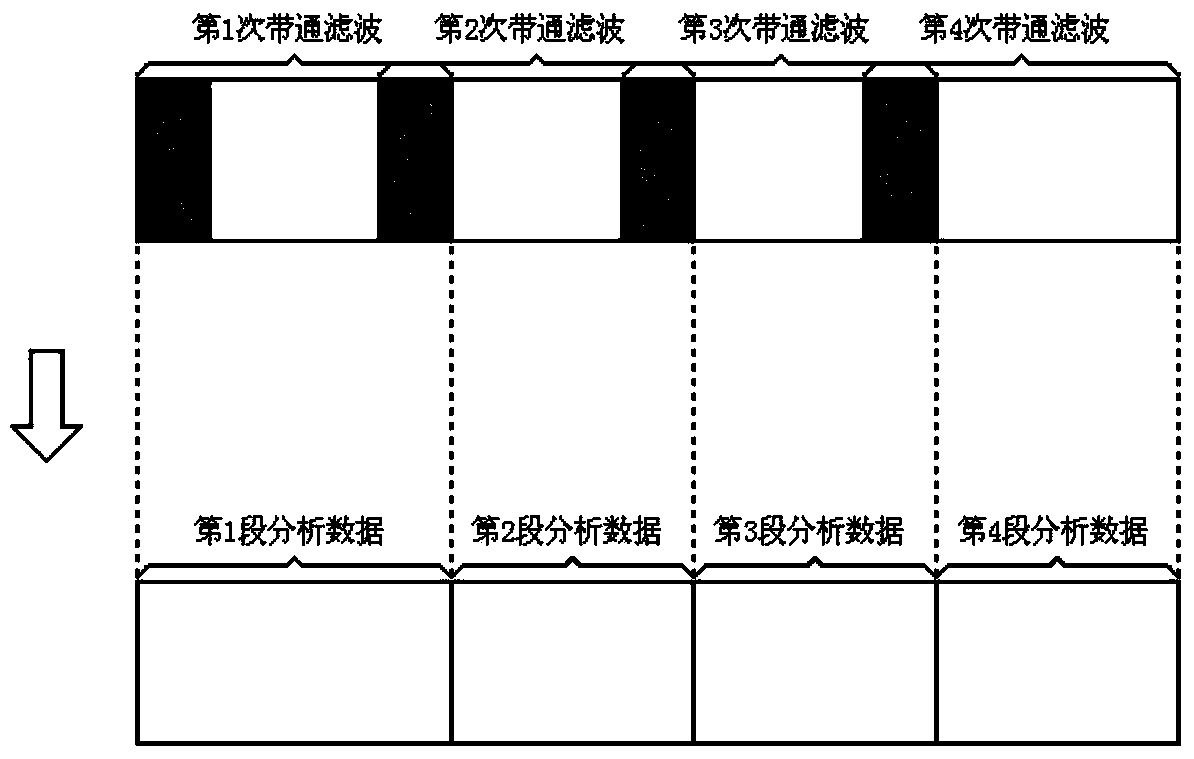

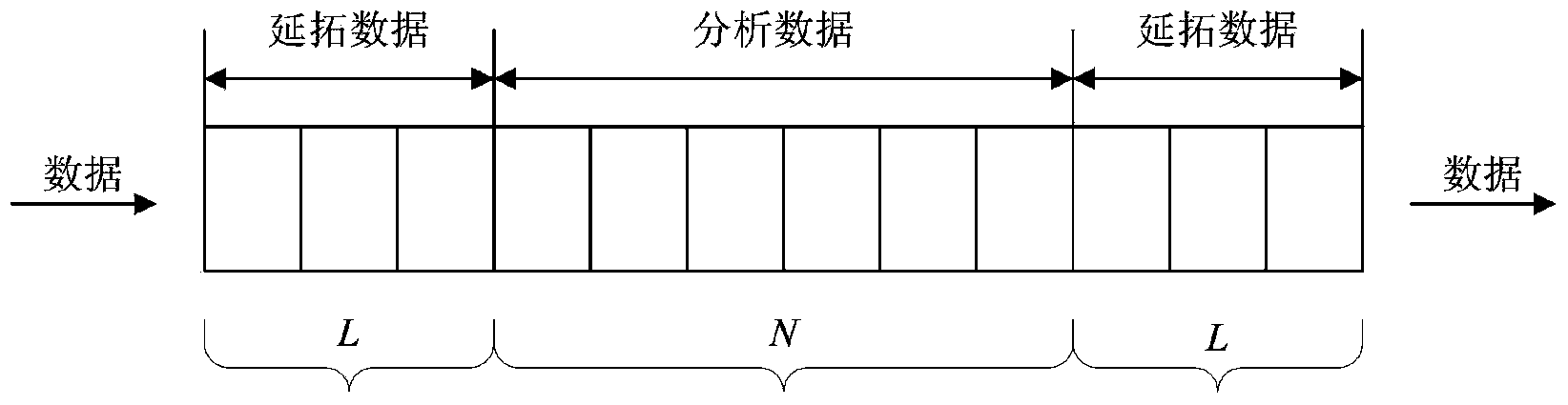

[0067] A2: Perform real-time band-pass filtering on the torsion angle signal, and perform multiple filtering on the same piece of data to solve the problem of band-pass filtering boundary distortion;

[0068] A3: Use the mode shape superposition method to calculate the real-time torsional stress change of each torsional vibration dangerous section of the shaft system by using the filtered one or more modal signals;

[0069] A4: Determine whether the real-time torsional stress of each to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com