Mechanical rock-breaking experiment device and method

A technology of experimental device and experimental method, applied in the direction of material inspection products, soil material testing, etc., can solve the problems of low degree of automation, imperfect function of drill bit test equipment, etc., and achieve the effect of large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

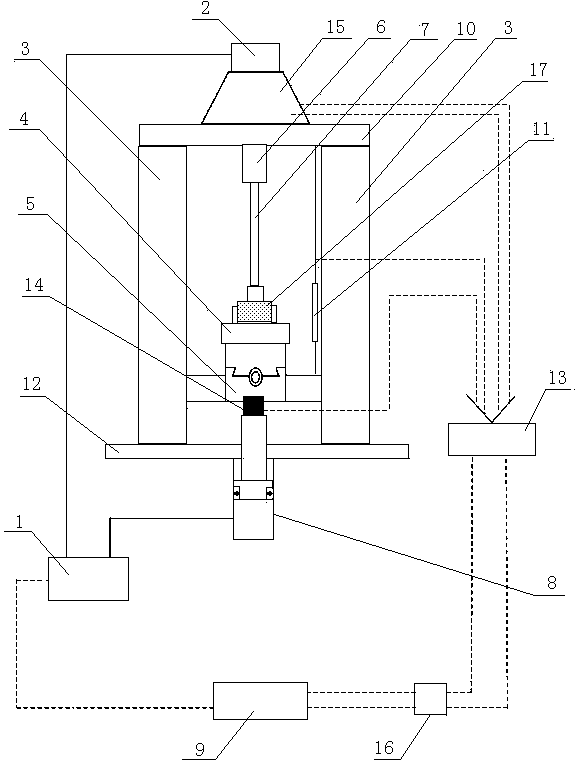

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, this mechanical rock-breaking experimental device includes a main frame, a hydraulic motor 2, a drill pipe 7, a centralizing sleeve 6, a hydraulic cylinder 8, a cross slide 5, a four-jaw chuck 4, a data acquisition system 13, a computer 16, a control Cabinet 9, the main frame is formed between the beam 10 and the base 12 through two columns 3, the two columns 3 have slideways, the lifting platform is arranged between the two columns 3 and is slidingly connected with the columns 3, and the cross slide 5 is arranged on the cylinder piston Above, the four-jaw chuck 4 is installed on the cross slide 5, the rock sample 17 is fixed on the four-jaw chuck 4, the cross slide 5 is connected to the motor, the displacement sensor 11 is set between the lifting table and the beam 10, and the hydraulic cylinder 8 is fixed Under the base 12, the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com