Optical fiber device and manufacturing method and application thereof

A technology of fiber optic devices and fiber lasers, which is applied to laser components, laser cooling devices, and the structure/shape of active media, etc., can solve the problems of limited thermal conductivity of copper, long-term and other problems, and achieve low inner cavity pressure and high safety , the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

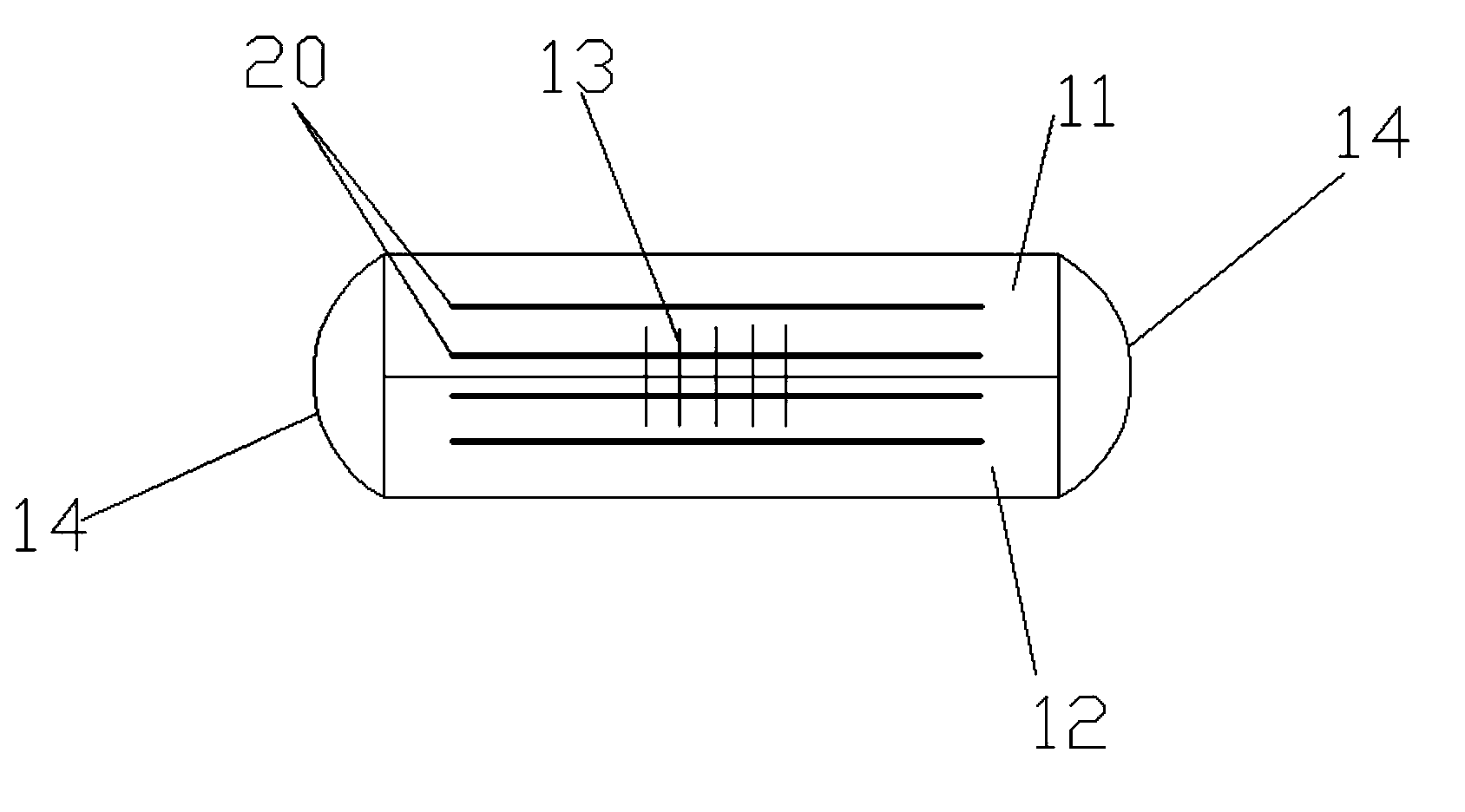

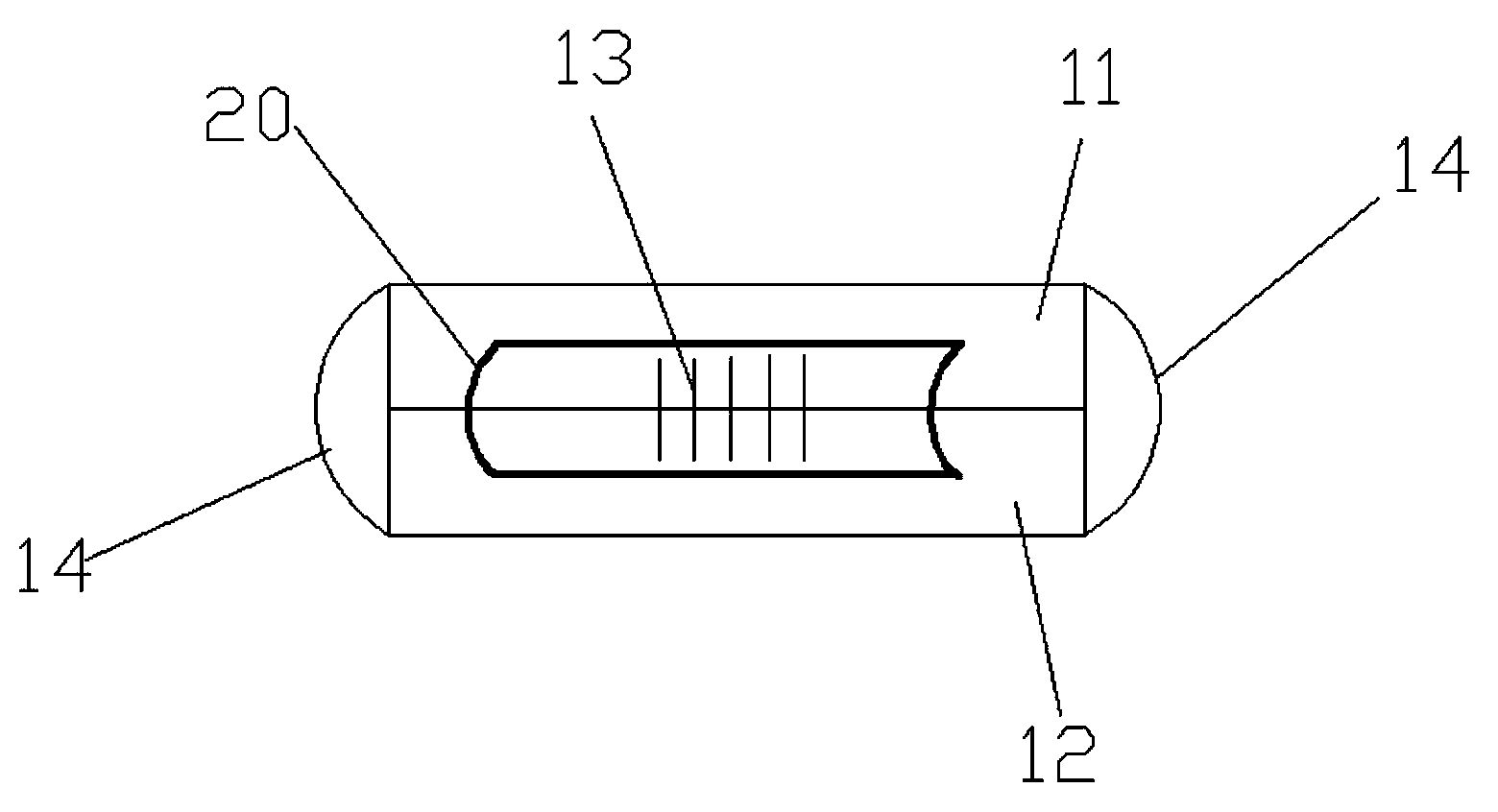

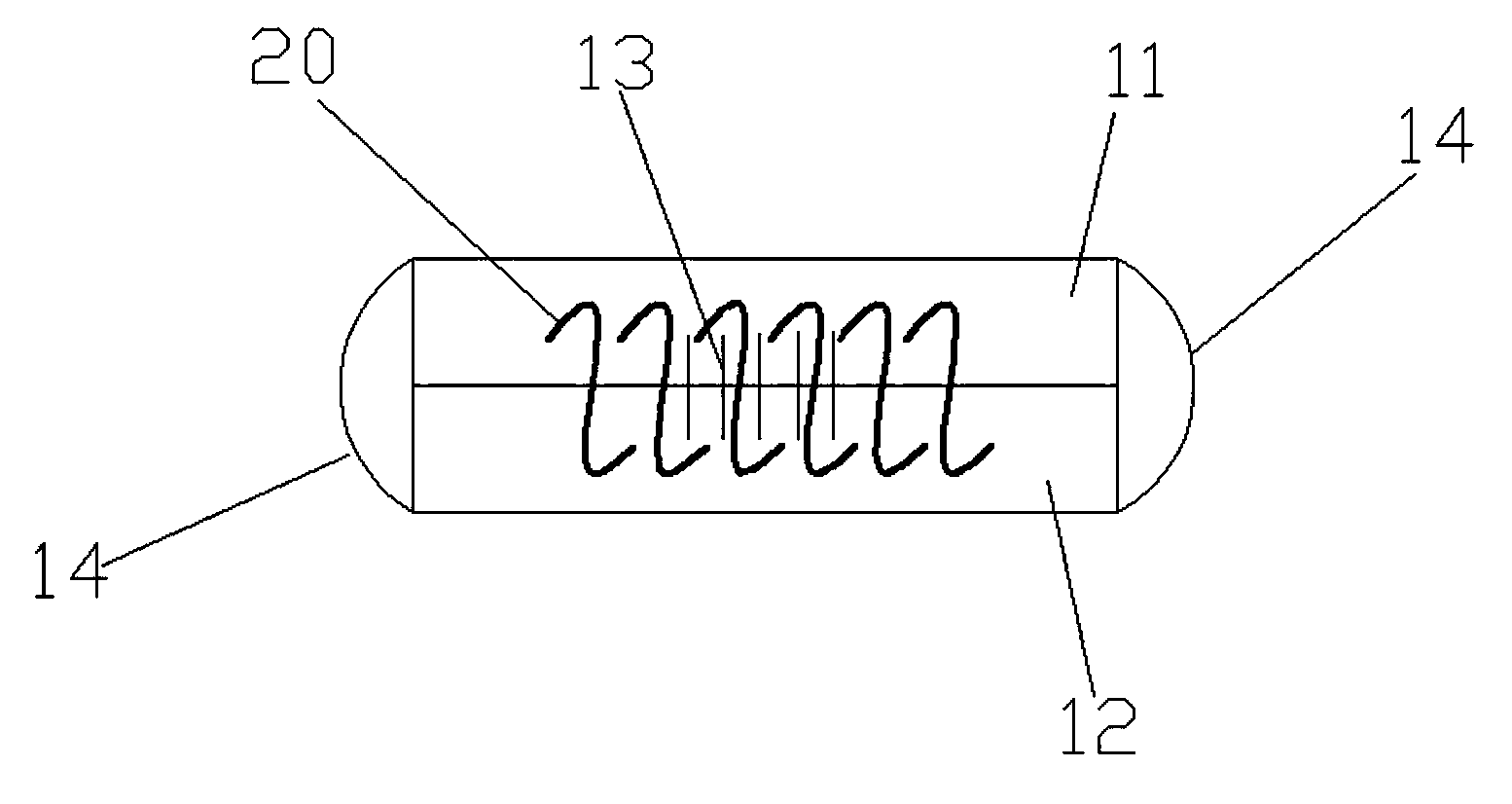

[0031] As shown in the figure, a fiber optic device is installed in a fiber laser. The fiber optic device is a fiber grating package, a saturable absorption mirror, and of course other devices. Such optical fiber devices all contain an inorganic thermal superconducting material 20 .

[0032] The fiber grating package includes an upper splint 11 , a lower splint 12 , a fiber grating 13 , a sealant 14 and a closed space of any shape. The enclosed space is filled with inorganic thermal superconducting material 20 . The fiber grating 13 is arranged on the joint surface of the upper splint 11 and the lower splint 12 . A closed space is provided inside the upper clamping plate 11 and the lower clamping plate 12, and the closed space can be in the shape of a strip, a hollow cylinder, a spiral, or other shapes. Both ends of the upper splint 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com