A far-infrared electric heating film

An infrared electric and hot film technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of wasting electric energy, low heat conversion efficiency, uneven temperature distribution, etc., and achieve good ductility, low solid content, Effect of Uniformity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

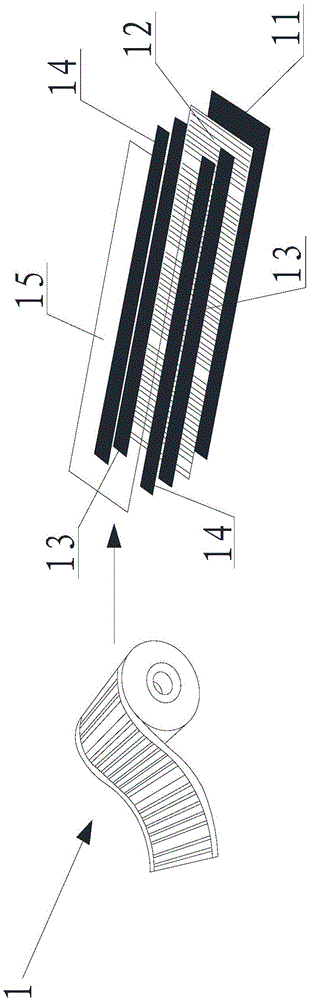

Image

Examples

Embodiment 1

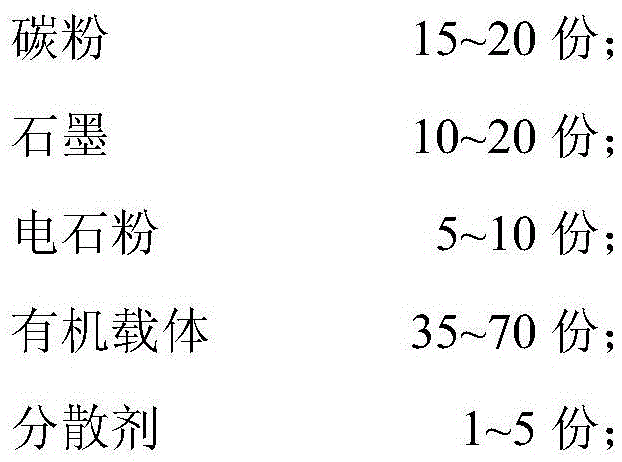

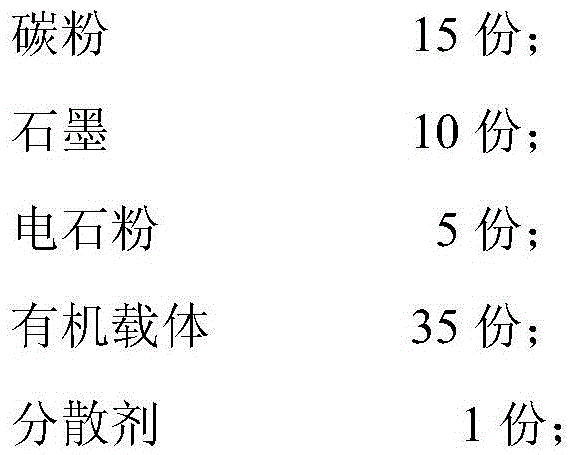

[0018] This embodiment provides a kind of exothermic carbon paste, its raw material formula includes the following components by weight:

[0019]

[0020] Wherein, the organic vehicle includes epoxy resin, polyurethane, acrylic resin and ethylene glycol oxalate, and their mass ratio is 10:8:15:40.

[0021] The production method of the heating carbon slurry is as follows: After fully mixing the above-mentioned raw material components, filter it with a 300-mesh filter cloth under a hydraulic environment, then fully grind it, and finally stir it to fully mix it. The carbon paste prepared by using this process formula and method has been well improved in terms of fineness and uniformity, and there will be no curling of the polyester film caused by excessive local temperature, which is conducive to improving the performance of the electric heating film. life. In addition, the carbon paste has PTC characteristics (that is, positive temperature coefficient characteristics). As it...

Embodiment 2

[0023] This embodiment provides a heating carbon slurry, which is roughly the same as the heating carbon slurry in Example 1, except that its raw material formula is:

[0024]

[0025] Wherein, the organic vehicle includes epoxy resin, polyurethane, acrylic resin and ethylene glycol oxalate, and their mass ratio is 20:15:20:60. In this embodiment, adding ethylene glycol butyl ether acetate (a coalescence aid) can promote the polymerization of the polymer material in the organic vehicle.

Embodiment 3

[0027] This embodiment provides a heating carbon slurry, which is roughly the same as the heating carbon slurry in Example 1, except that its raw material formula is:

[0028]

[0029] Wherein, the organic carrier includes epoxy resin, polyurethane, acrylic resin and ethylene glycol oxalate, and their mass ratio is 20:12:18:70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com