Compositions for paint

A composition and coating technology, applied in the field of paint paste, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation process of the granular kaolin clay used in the present invention may also include one or more comminuting steps, such as grinding or milling. Light comminution of the coarse kaolin is used to provide its proper stratification. The comminution can be performed by using plastic (eg nylon) beads or granules, sand or ceramic grinding or grinding aids. Coarse kaolin can be refined to remove impurities and improve physical properties using known procedures. Kaolin clay can be processed by known particle size fractionation procedures such as sieving and centrifugation (or both are used) to obtain 50 value or size distribution of particles.

[0078] The particle size distribution of the inorganic particulate material will be one suitable for use in coatings. Suitable particle sizes are as described below for primary and effector pigments.

[0079] In one embodiment, the inorganic particulate material used in the microfibrillating step may have a particle si...

Embodiment 1

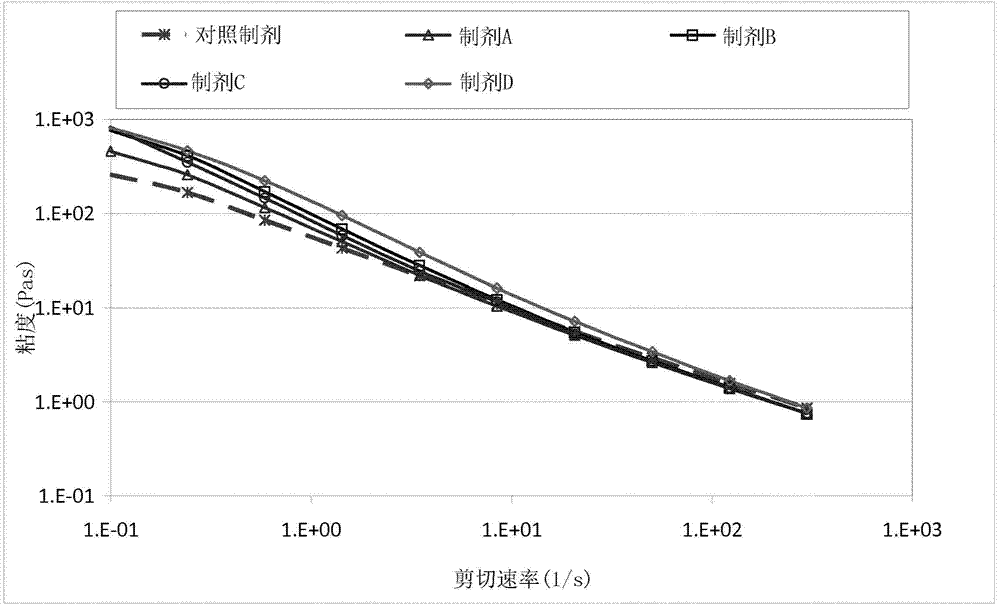

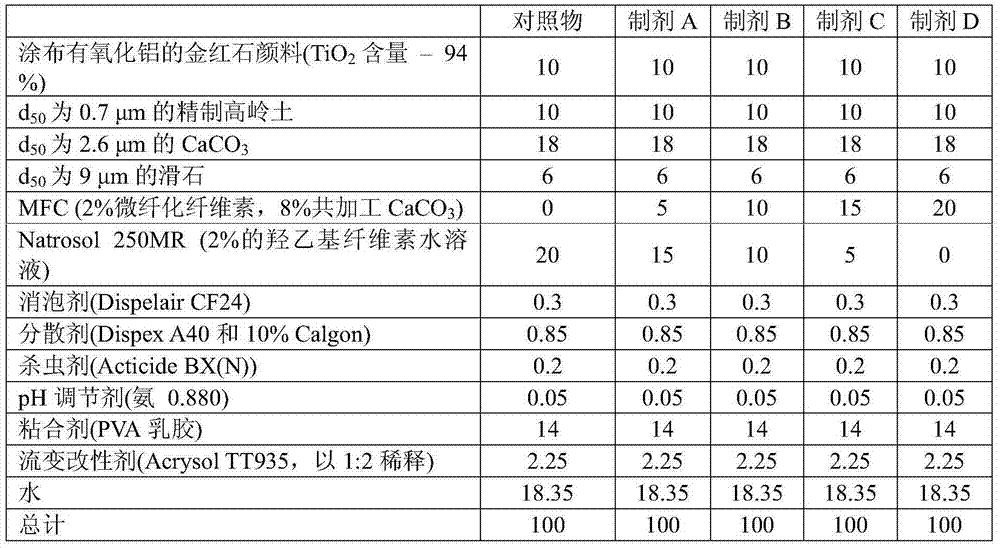

[0167] A series of coating formulations were mixed under high shear in which microfibrillated cellulose was used to progressively replace the standard hydroxyethyl cellulose component. The details of the formulations are shown in Table 1. Microfibrillated cellulose (MFC) samples were prepared by adding d 50 Ground calcium carbonate of 1.4 μm was co-ground with Botnia northern bleached kraft pulp in an agitated media mill at a specific energy of 2500 kWh / metric ton of pulp. The MFC used in the paint formulation was supplied as an aqueous slurry comprising 2% by weight microfibrillated cellulose and 8% by weight ground calcium carbonate.

[0168] figure 1 The rheological curves (viscosity-shear rate function) of the formulations used are shown. Use of microfibrillated cellulose prepared by the method described herein in place of hydroxyethyl cellulose rheology modifier maintains near constant coating viscosity at high shear rates and significantly increases viscosity at low s...

Embodiment 2

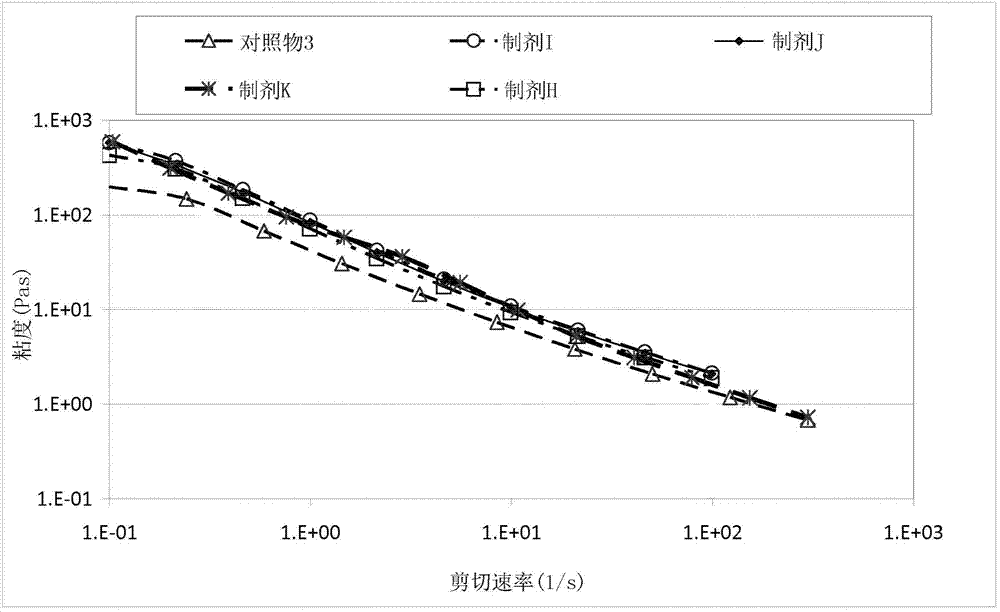

[0175] Mix a second series of paint formulations under high shear, this time using coarse calcium carbonate (d 50 6.5 μm) to replace part of the talc, wherein microfibrillated cellulose is used to progressively replace the standard hydroxyethyl cellulose component. The details of the formulations are shown in Table 3 and the properties of the coating films are shown in Tables 4a and 4b.

[0176] The cracking propensity of these coatings was assessed by making the drawdown film increase in thickness across its width and recording the film thickness in microns at which it first cracked after drying. The thicker the thickness at which cracking is observed, the lower the tendency of the coating to crack when in use.

[0177] Cracks are determined in the following way:

[0178] Materials and equipment:

[0179] -Substrate: Gypsum board

[0180] -Wedge coater (300μm~1500μm wet film thickness)

[0181] - Bar coater series (1500μm, 1750μm, 2000μm, 2250μm and 2500μm wet film thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com