Method for solution hardening of a cold deformed workpiece of a passive alloy, and a member solution hardened by the method

A cold deformation and alloy technology, applied in metal material coating process, solid diffusion coating, coating and other directions, to achieve the effect of less time execution and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0081] Lock and key washers of cold deformed austenitic stainless steel (AISI316) are hardened by two methods of the prior art.

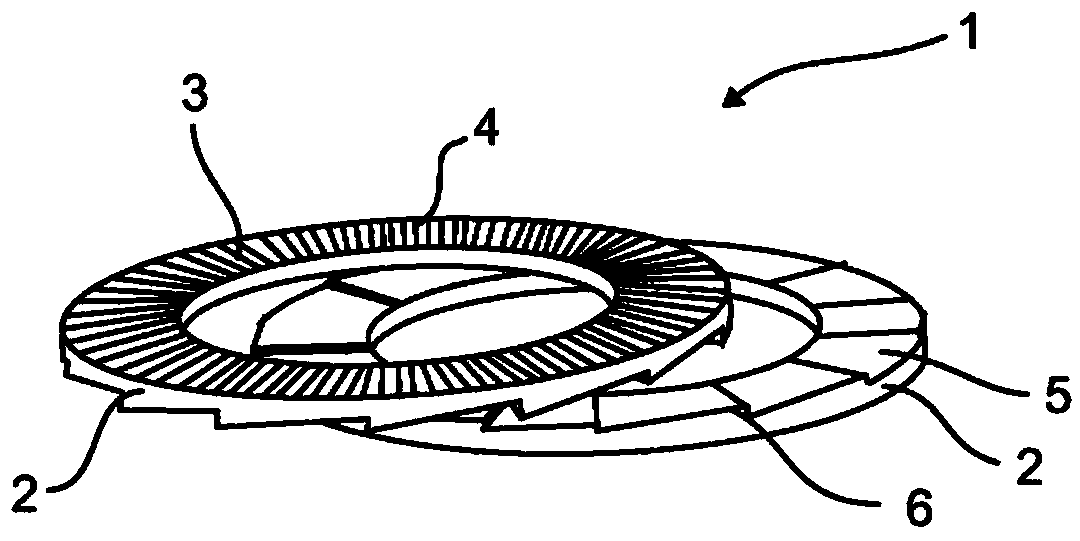

[0082] Two identical key washers of cold-formed austenitic stainless steel (AISI316L) were hardened. FIG. 2 shows a key washer set 1 of said key washer 2 and its use. Each washer 2 has a first side 3 with radial teeth 4 and an opposite cam side 5 with a cam 6 . During use of the key lock washer set 1 , the washer 2 is placed facing each other with the cam side 5 as shown. The two lock and key washers are solution hardened using nitrogen and carbon at a temperature of 440°C. One gasket was hardened using the method disclosed in PA2011 70208, ie in a high temperature process followed by a low temperature process, and the other gasket was directly case hardened using the same low temperature process, ie prior art. The gasket was analyzed using an optical microscope. image 3 and Figure 4 Shown on the left is a gasket surface hardened only using a...

example 2

[0085] Cold deformed austenitic stainless steel (AISI 316) was hardened by methods of the prior art as well as methods disclosed in PA2011 70208.

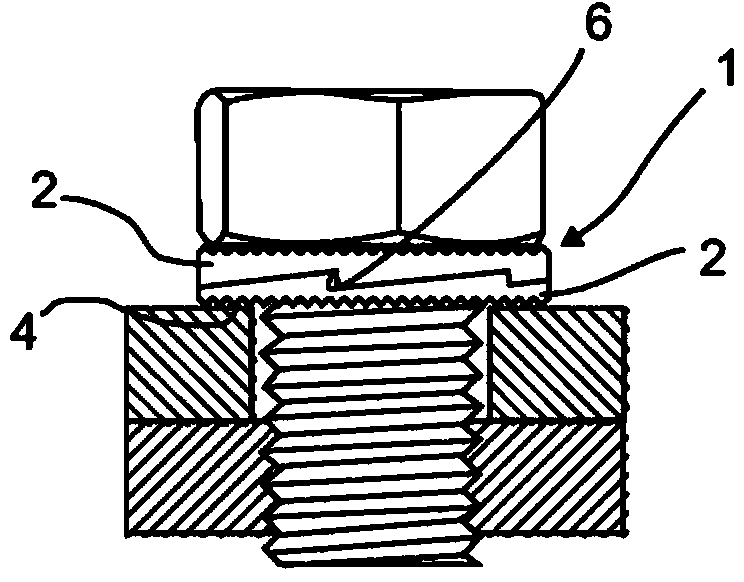

[0086] Two identical parts (back ferrules) of cold deformed austenitic stainless steel (AISI316) were solution hardened using nitrogen and carbon at a temperature of 440°C. One part was hardened using the method disclosed in PA2011 70208, ie in a high temperature process followed by a low temperature process, and the other part was directly case hardened using the same low temperature process. Figure 5 On the left is shown a microstructural analysis using an optical microscope of a part that was case hardened using only the nitrocarburizing process using a gas containing nitrogen and carbon at a temperature of 440°C 12 hours at atmospheric pressure. The outer surface in the nitrogen-containing region exhibits partial sensitization with significant CrN precipitates appearing on the outermost surface. Figure 5 On the right is sho...

example 3

[0088] Cold deformed austenitic stainless steel (AISI 304) plates were hardened by methods of the prior art as well as methods disclosed in PA2011 70208.

[0089]Two identical cold-rolled (deformed) austenitic stainless steel (AISI 304) plates were solution hardened using nitrogen and carbon at a temperature of 440°C. One part was hardened using the method disclosed in PA2011 70208, ie in a high temperature process followed by a low temperature process, and the other part was directly case hardened using the same low temperature process. Figure 6 Shown on the left is a part surface-hardened only using the nitrocarburizing process using a gas containing nitrogen and carbon at a temperature of 440°C for 20 hours and subsequently exposed to The corrosion test was carried out in 14% sodium hypochlorite solution for 70 minutes. Figure 6 On the right a part hardened with the method disclosed in PA2011 70208 is shown. The part is exposed to a nitrogen-containing atmosphere at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com