Resist adhesion improver and method for producing copper wiring line

An adhesion and resist technology, which can be used in the manufacture of printed circuits, semiconductor/solid-state device manufacturing, and removal of conductive materials by chemical/electrolytic methods, which can solve problems such as not helping to improve the adhesion of resist films. , to achieve the effect of improving the adhesion and reducing the amount of side erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Hereinafter, the present invention will be described more specifically by way of examples, but the following description is mainly for illustration, and the present invention is not limited to these examples.

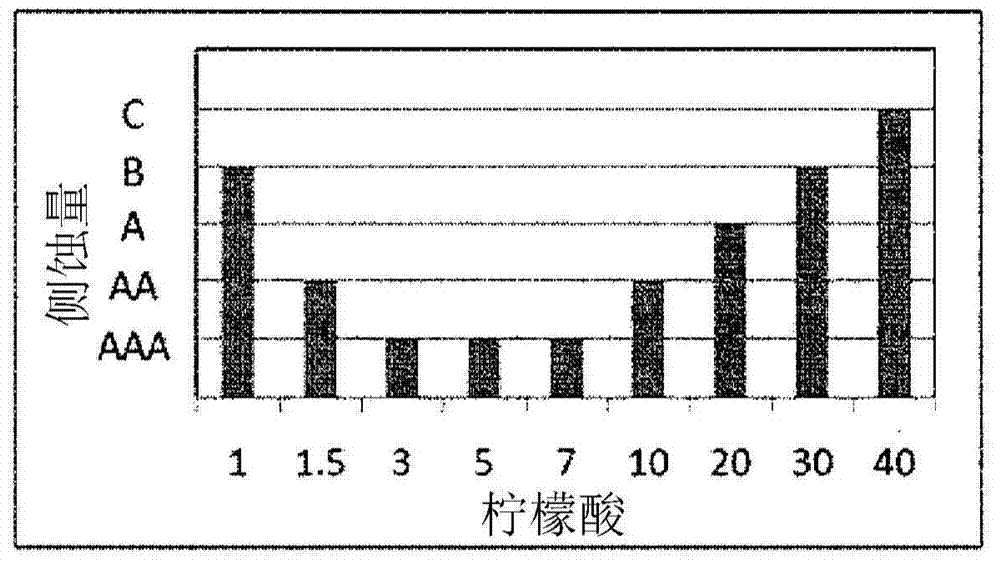

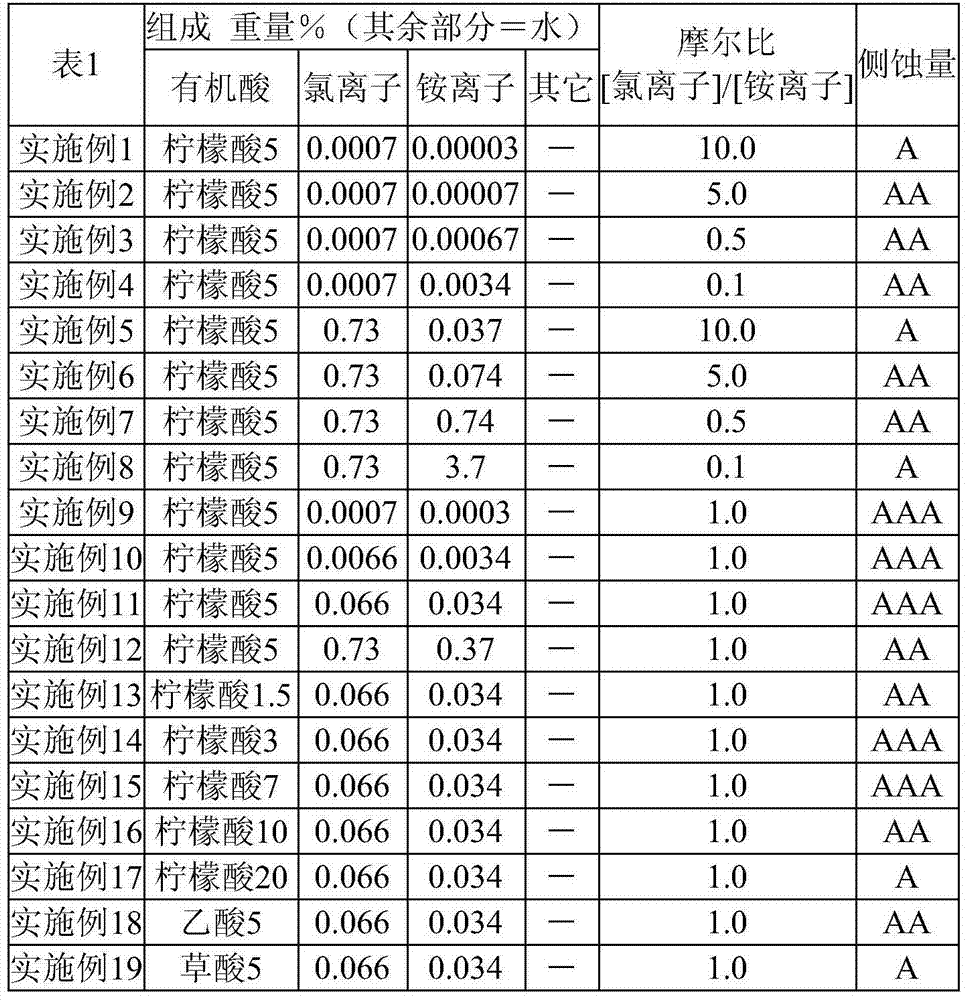

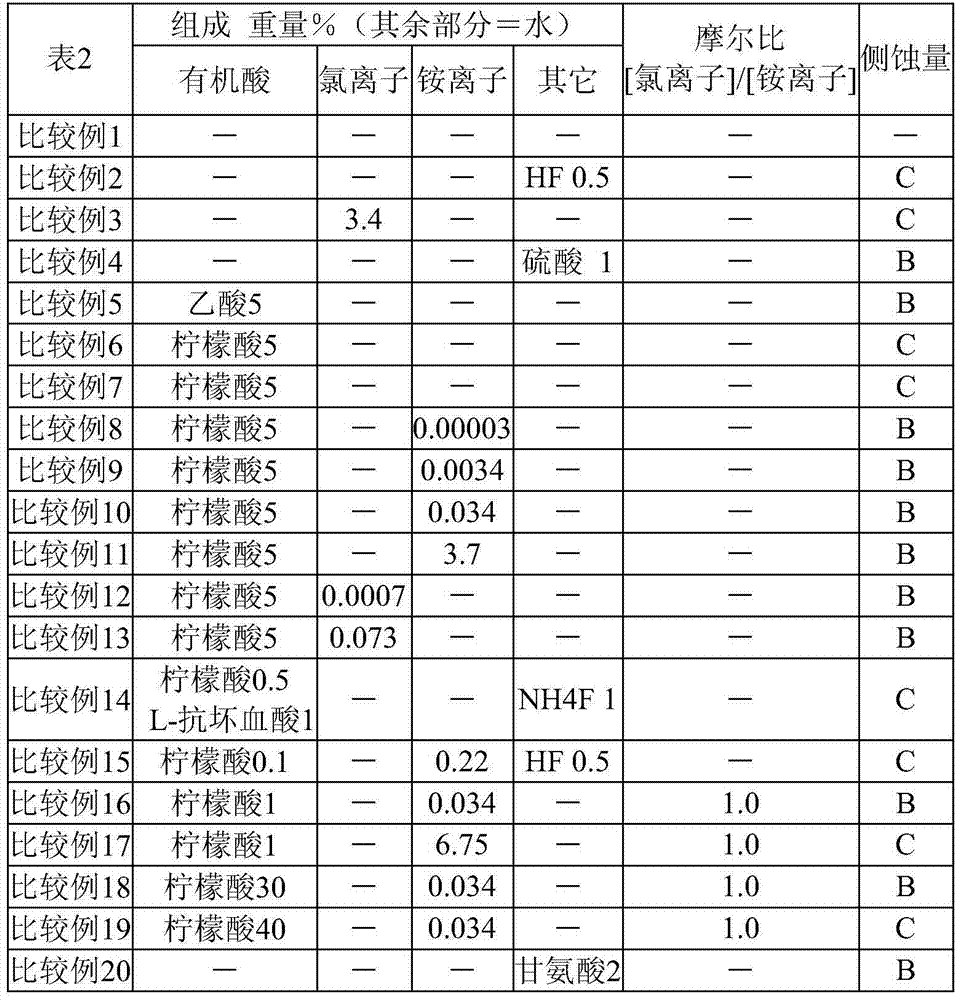

[0047] Table 1 shows the composition of each evaluation liquid used in Examples 1-19, and Table 2 shows the composition of each evaluation liquid used in Comparative Examples 1-20. In addition, the following evaluations were performed using these evaluation liquids, and the results are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com