Lignin modified phenolic resin, foam thereof, preparation method of resin, and preparation method of foam

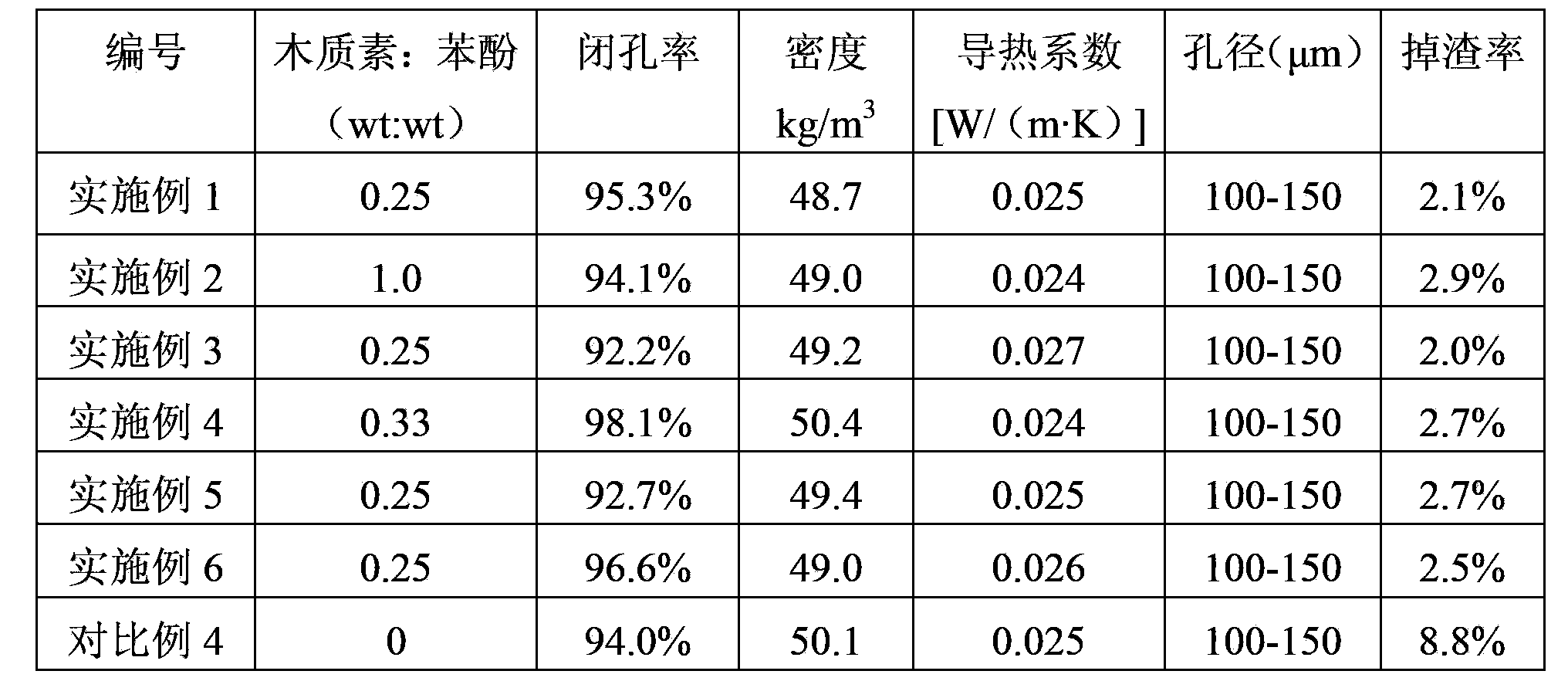

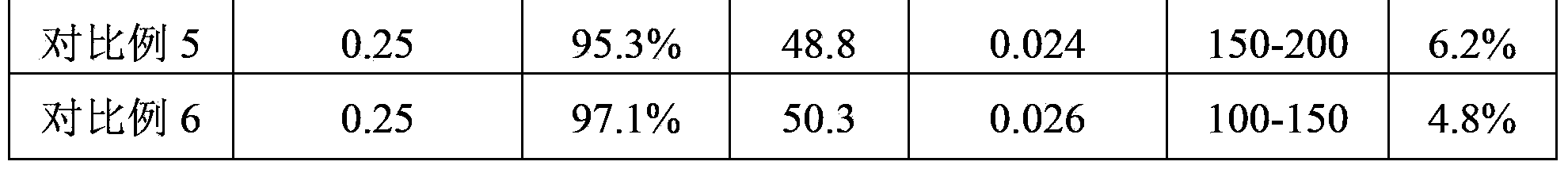

A phenolic resin foam and phenolic resin technology are applied in the fields of lignin-modified phenolic resin, foam and its preparation, which can solve the problems of long gel time, increased production cost, reduced thermal insulation performance, and reduced foam strength, and achieves good thermal insulation performance. , The effect of high curing activity and low slag removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1. Preparation of phenolized lignin

[0060] Take 100g of lignin, add it into a high-temperature and high-pressure reactor, then add 100g of phenol, stir, then add 3g of phosphoric acid, stir, close the reactor, and replace the air in the reactor with nitrogen. Raise the temperature to 250°C for 2 hours (reaction pressure about 4MPa). After the reaction is completed, pass condensed water to cool down the reactor, then open the exhaust valve to release the pressure, and open the reactor to obtain a phenol solution of phenolized lignin (Mn=617).

[0061] 2. Preparation of Lignin Modified Phenolic Resin

[0062] Add 15.0 g (0.1594 mol) of phenol to 10.0 g of lignin phenolization products (containing 0.0531 mol of phenol), mix well, heat up to 50 ° C, adjust its pH value to 9 with 50 wt % NaOH aqueous solution; then add 34.50 g (that is, 0.4251mol formaldehyde) formaldehyde aqueous solution with a concentration of 37wt%; react the reaction system at a constant temperature...

Embodiment 2

[0067] One, the preparation of phenolized lignin: same as embodiment 1.

[0068] 2. Preparation of Lignin Modified Phenolic Resin

[0069] Take 10.0g of lignin phenolization product (containing 0.0531mol of phenol) in a three-necked flask without adding phenol, raise the temperature to 50°C, adjust its pH value to 8 with 50wt% NaOH aqueous solution, and mix 8.62g (0.1062mol of formaldehyde ) formaldehyde solution with a concentration of 37wt% was added dropwise; the reaction system was reacted at a constant temperature of 50°C for 3h (including the time consumed by dropping formaldehyde), then raised to 80°C for a constant temperature of 3h, and then heated to 90°C for 1h; the reaction The temperature of the system dropped rapidly to below 60°C, and the reaction was terminated. Add p-toluenesulfonic acid to adjust the pH value to neutral; then dehydrate the product to obtain lignin-modified phenolic resin. Resin indicators such as resin solid content and gel time are shown i...

Embodiment 3

[0073] One, the preparation of phenolized lignin: same as embodiment 1.

[0074] 2. Preparation of Lignin Modified Phenolic Resin

[0075] Take 10.0g of lignin phenolization products (containing 0.0531mol of phenol) into a three-necked flask, add 15.0g (0.1594mol) of phenol, raise the temperature to 60°C, adjust its pH value to 9 with 50wt% KOH aqueous solution, drop by drop Add 34.50g (0.4251mol formaldehyde) formaldehyde aqueous solution with a concentration of 37wt%; react the reaction system at a constant temperature of 60°C for 2h (including the time consumed by dropping formaldehyde), then raise the temperature to 70°C for 5h, then raise the temperature to 90°C for reaction 0.2h. The temperature of the reaction system was rapidly lowered to below 60°C, and the reaction was terminated. Add p-toluenesulfonic acid to adjust the pH value to neutral; then dehydrate the product to obtain lignin-modified phenolic resin. Resin indicators such as resin solid content and gel ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com