Device and method for measuring gas film gap of dynamic pressure motor on basis of simultaneous phase shifting interferometry

A synchronous phase-shifting, dynamic pressure motor technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of reducing the stability of the indication value, the repeatability of the measurement, the reduction of the measurement accuracy, the change of the reflectivity, etc. Accurate measurement, high resolution, and the effect of large measuring working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

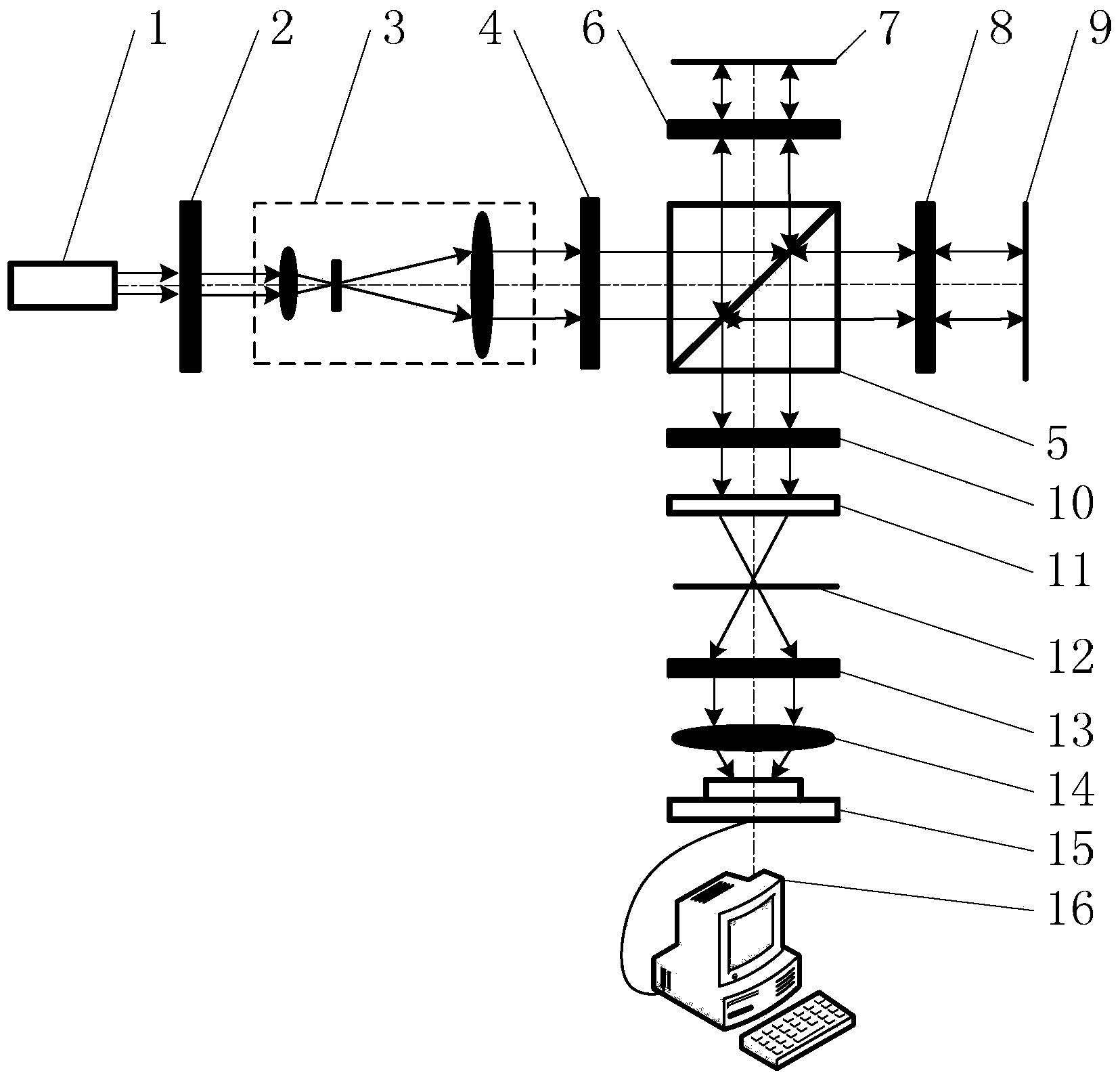

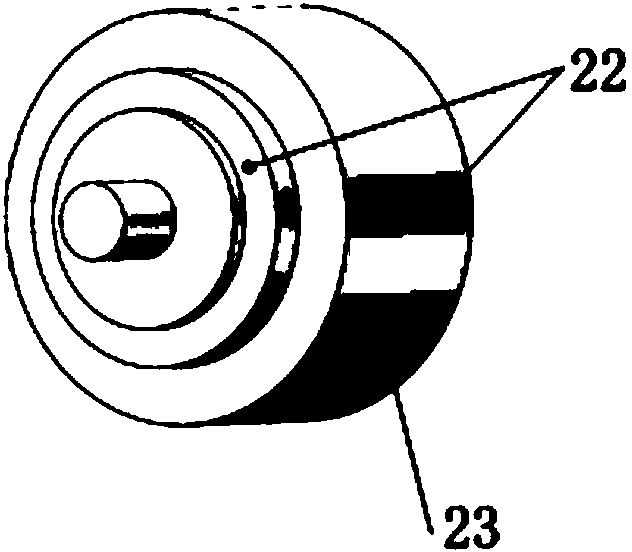

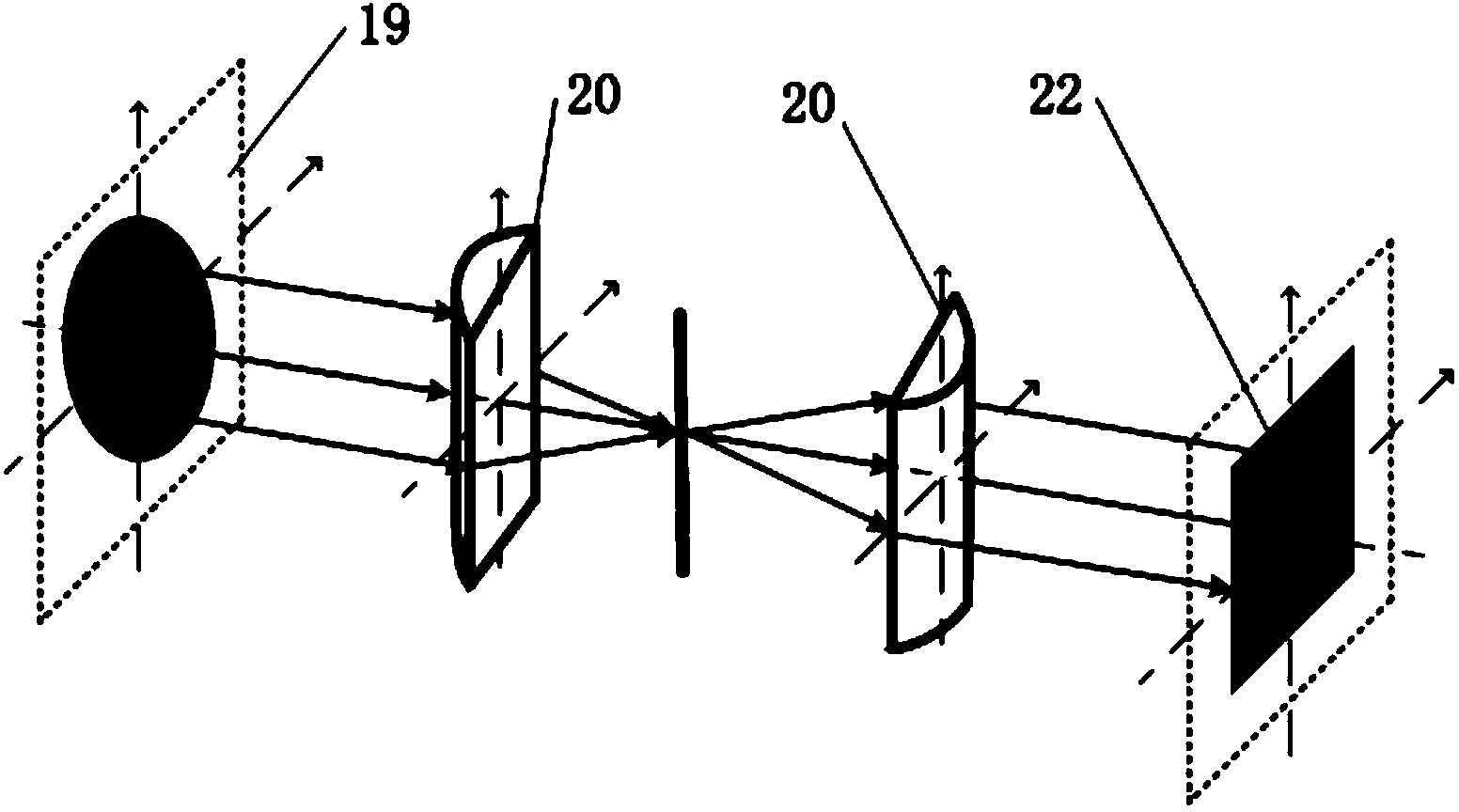

specific Embodiment approach 1

[0038]Specific Embodiment 1: It will be described in conjunction with the accompanying drawings. The dynamic pressure motor air film gap measurement device based on synchronous phase-shifting interference in this embodiment is composed of a laser 1, a linear polarizer 2 and a collimating beam expander 3. The light source part, 1 / 2 wave plate 4, polarizing beamsplitter prism 5, first 1 / 4 wave plate 6, plane reflector 7 together with the second 1 / 4 wave plate 8, and the surface to be measured 9 form a Teman Green interference device, and the reference for merging again The light and the measurement light pass through the third 1 / 4 wave plate 10 and the Longji grating 11 to achieve equal light intensity splitting, and the separated light is selected by the diaphragm 12 to select the required four-way light through the four-quadrant polarizer 13 to achieve phase shifting, and finally The interferogram is collected by the first lens 14, the CCD 15 and the computer 16, and the image...

specific Embodiment approach 2

[0039] Specific Embodiment 2: It will be described in conjunction with the accompanying drawings. The measurement method of this embodiment can realize high-precision measurement of the motor air film thickness by using the above-mentioned synchronous phase-shifting interferometry device. The specific implementation process is: first, the laser 1, the line The polarizer 2 and the collimator beam expander 3 form the light source part to produce linearly polarized light with a large spot. The linearly polarized light is converted into a linearly polarized light that is 45° different from the original vibration direction through the 1 / 2 wave plate 4, and is split by polarization. The prism 5 is divided into two beams of light whose polarization directions are perpendicular to each other and equal light intensity; secondly, the first beam of light passes through the first 1 / 4 wave plate 6 and the plane reflector 7, and the second beam of light passes through the second 1 / 4 wave plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com