Peanut seed coating additive

An additive and seed technology, applied in the field of peanut seed coating additives, can solve the problems of low seed vigor, slow emergence, rotten seeds, etc., and achieve the effect of promoting seed germination speed and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A peanut seed coating additive, consisting of the following parts by weight: 15-20 Tianda 2116, 3-6 brassinolide, 4-7 gibberellin, 2-5 kinetin, 3-6 6-benzylaminopurine , 4~7 naphthalene acetic acid, 4~6 indole acetic acid, 3~5 salicylic acid, 2~4 triacontanol, 10~14 amino oligosaccharin, 2~3 methylcellulose.

[0011] Further, the application method of the peanut seed coating additive is: mixing it with the seed coating agent and then dressing the seeds, and the amount of the peanut seed coating additive is 52-84 g per 15-17 kg of peanut seeds.

[0012] Described seed coating agent is the seed coating agent used in the prior art.

Embodiment 2

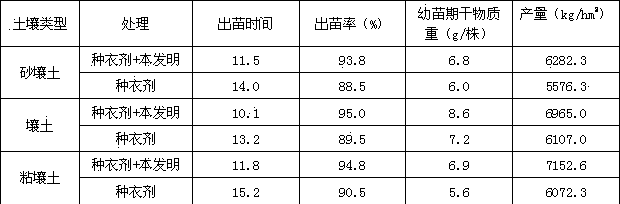

[0014] Dahuasheng Huayu No. 22 Field Test

[0015] Table 1 result shows, on sandy loam soil, the peanut seedling emergence time of the present invention+seeding agent (imidacloprid seed-coating agent) seed dressing shortens 2.5d respectively than simple seed-coating agent seed-dressing time, and the emergence rate improves 5.3 percentage points, and peanut seedling The weight of dry matter in the first stage increases by 13.3%, and the pod output in the mature stage improves by 12.7%; on loam, the emergence time of peanut seeds of the present invention+seeding agent seed dressing is shortened by 3.1d respectively than that of simple seed dressing agent seed dressing, and the emergence rate improves by 5.5% %, the weight of dry matter in peanut seedling stage increases by 19.4% respectively, and the pod output in mature stage improves by 14.0%; on clay loam, the emergence time of peanut seeds of the present invention+seeding agent seed dressing is shortened respectively than sim...

Embodiment 3

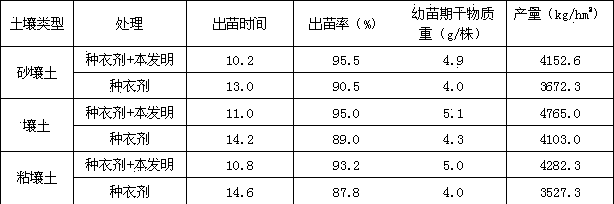

[0019] Field experiment of Xiaopeansheng Huayu No. 23

[0020] Table 2 result shows, on sandy loam soil, the peanut seed emergence time of the present invention+seeding agent seed dressing shortens 2.8d respectively than simple seed coating agent seed dressing, and emergence rate improves 5.0 percentage points, and the dry matter weight of peanut seedling stage seedling Increased by 22.5% respectively compared with the control, and the pod yield in the mature stage increased by 13.1%; on loam soil, the emergence time of the peanut seeds of the present invention+seeding agent was shortened by 3.2d, and the emergence rate increased by 6.0 percentage points compared with that of the simple seed dressing , the dry matter weight of the seedlings in the peanut seedling stage increased by 18.6% respectively compared with the contrast, and the pod yield in the mature stage increased by 16.1%; Shorten 3.8 days, the emergence rate increased by 5.4 percentage points, the dry matter weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com