Black garlic sauce and black garlic moon cake stuffing containing same

A black garlic paste, black garlic technology, applied in application, food preparation, food science and other directions, can solve the problems of unsuitable black garlic moon cake fillings, short fermentation time, etc., to improve immunity, unique flavor, less oil content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

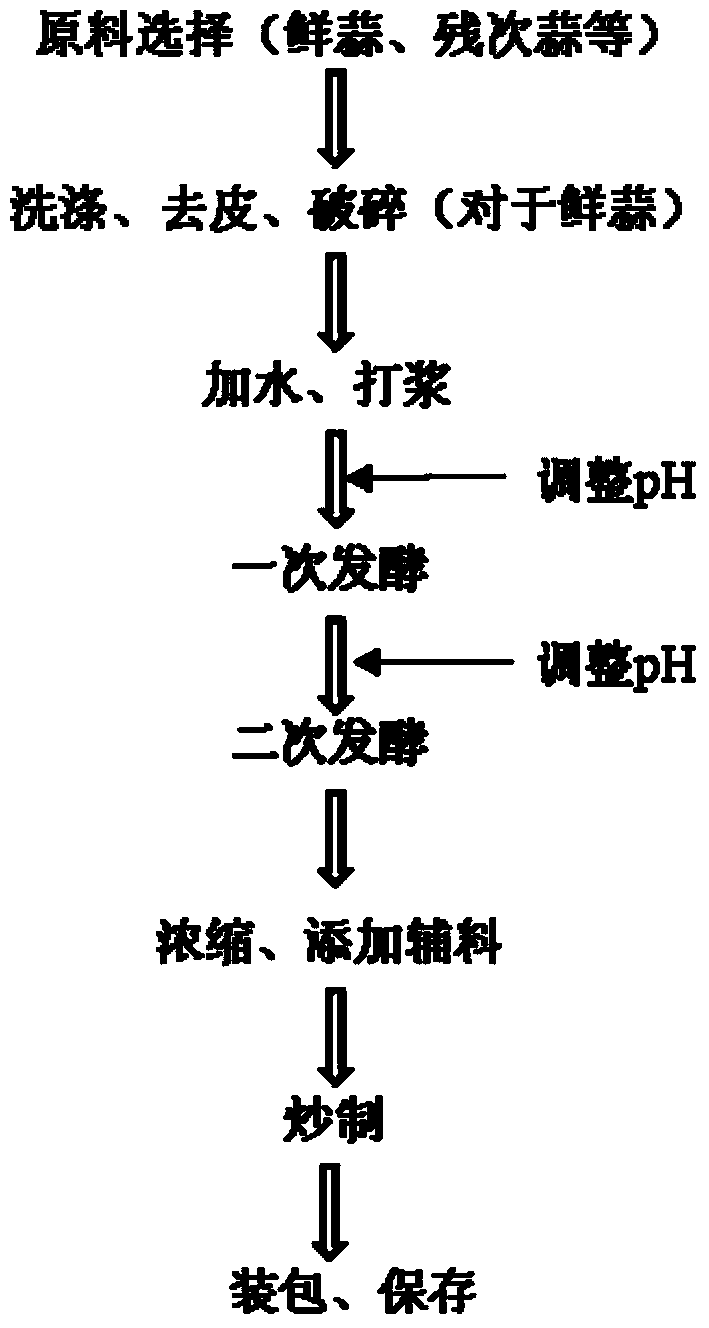

Method used

Image

Examples

Embodiment 1

[0040] (1) Garlic pulp preparation: after washing and peeling the garlic of 100 parts by mass, add 100 parts by mass of water and crush it in a beater to obtain fresh garlic pulp;

[0041] (2) Fermentation for the first time: After adjusting the pH value of the fresh garlic pulp after crushing with 1% (W / W) citric acid to be 5.5, adding the salt that the final mass percentage is 1% (W / W), at 40 Ferment at ℃ for 2h;

[0042] (3) Second fermentation: after the first fermentation, adjust the pH value of the fermented liquid to 6.5 with baking soda, raise the temperature to 100° C. and ferment for 1.1 h, and obtain black garlic sauce after the fermented liquid turns black;

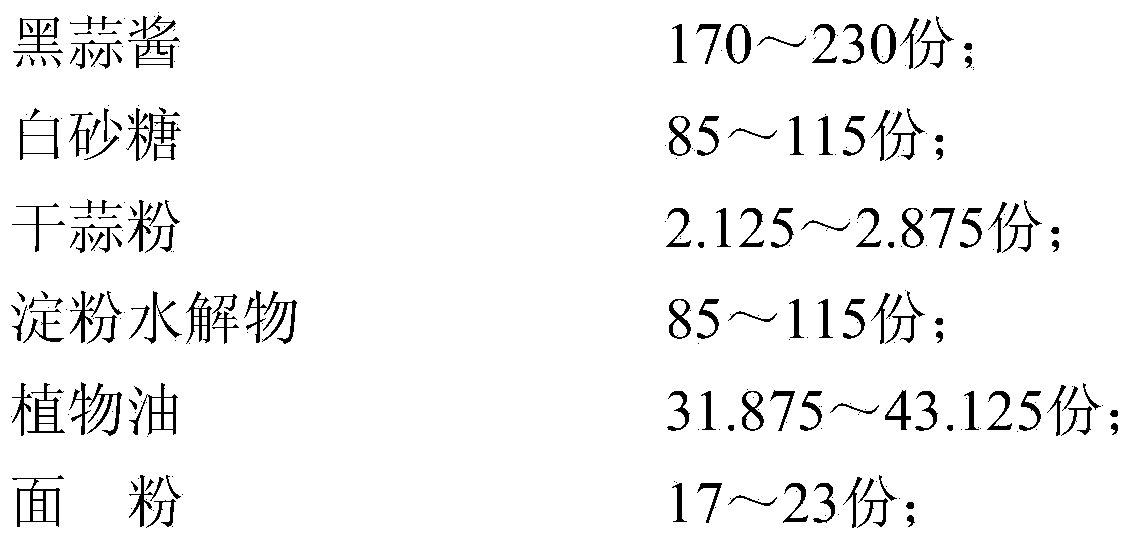

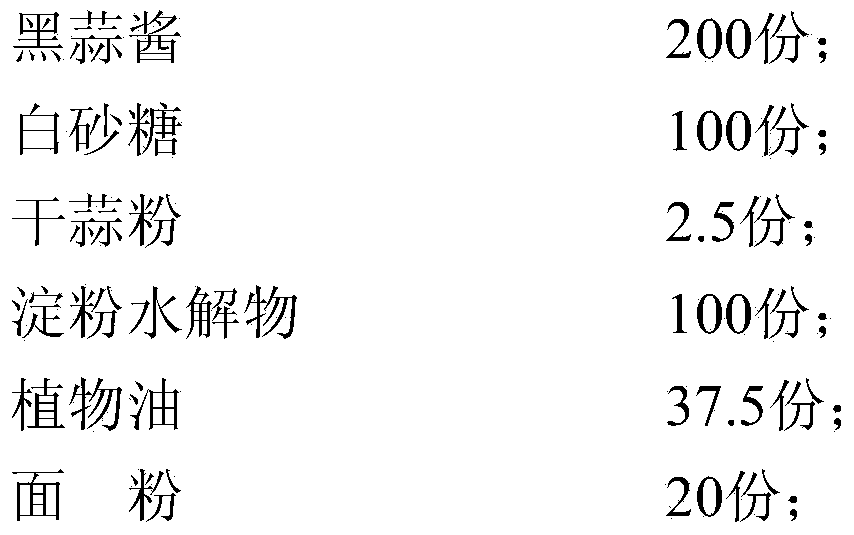

[0043] (4) Adding and mixing auxiliary materials: continue to heat the black garlic sauce (170 parts by mass), evaporate the water to thicken while stirring, add 85 parts by mass of white sugar, mix and dissolve; then add 85 parts by mass of maltose syrup (DE=72) and 2.125 parts by mass of dry garlic powder s...

Embodiment 2

[0046] (1) Garlic pulp preparation: first wet the dried garlic powder of 45 parts by mass with 315 parts by mass of water, soak it until there is no clear water, and crush it with a mixer to obtain garlic pulp;

[0047] (2) First fermentation: use 1% (W / W) malic acid to adjust the pH value of crushed garlic pulp to 5, add salt with a final mass percentage of 1% (W / W), and ferment at 50°C 1.3h;

[0048] (3) Second fermentation: after the first fermentation, adjust the pH value of the fermented liquid to 6 with sodium bicarbonate, raise the temperature to 60° C. and ferment for 3 hours. After the fermented liquid turns black, black garlic sauce is obtained;

[0049] (4) Adding and mixing auxiliary materials: continue to heat the black garlic sauce (take 200 parts by mass), evaporate the water to thicken while stirring, add 105 parts by mass of white granulated sugar to mix and dissolve; then add 105 parts by mass of glucose pulp (DE=72), 2.5 parts by mass of dry garlic powder s...

Embodiment 3

[0052] (1) Garlic pulp preparation: after washing and peeling the garlic of 100 mass parts, add 200 mass parts of water and crush in a beater to obtain fresh garlic pulp;

[0053] (2) Fermentation for the first time: use 1% (W / W) lactic acid to adjust the pH value of the crushed fresh garlic pulp to 6.0, add salt that is 1% (W / W) in the final mass percentage, at 55 ° C Ferment for 1h;

[0054] (3) Second fermentation: After the first fermentation, adjust the pH value of the fermented liquid to 7.0 with baking soda, raise the temperature to 80° C. and ferment for 2 hours. After the fermented liquid turns black, black garlic sauce is obtained;

[0055] (4) Adding and mixing auxiliary materials: take 230 parts by mass of black garlic sauce and continue heating, evaporate the water to thicken while stirring, add 115 parts by mass of white sugar, mix and dissolve; then add 115 parts by mass of starch dextrin (DE=72), 2.875 parts by mass of dry garlic powder soaked in maltose syrup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com