A method for manufacturing a hollow insulation riser with a partition

A technology for thermal insulation risers and production methods, which is applied in the field of special steel casting, can solve problems such as difficulty in production and production, and achieve the effects of reducing heat conduction efficiency, improving thermal insulation performance, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

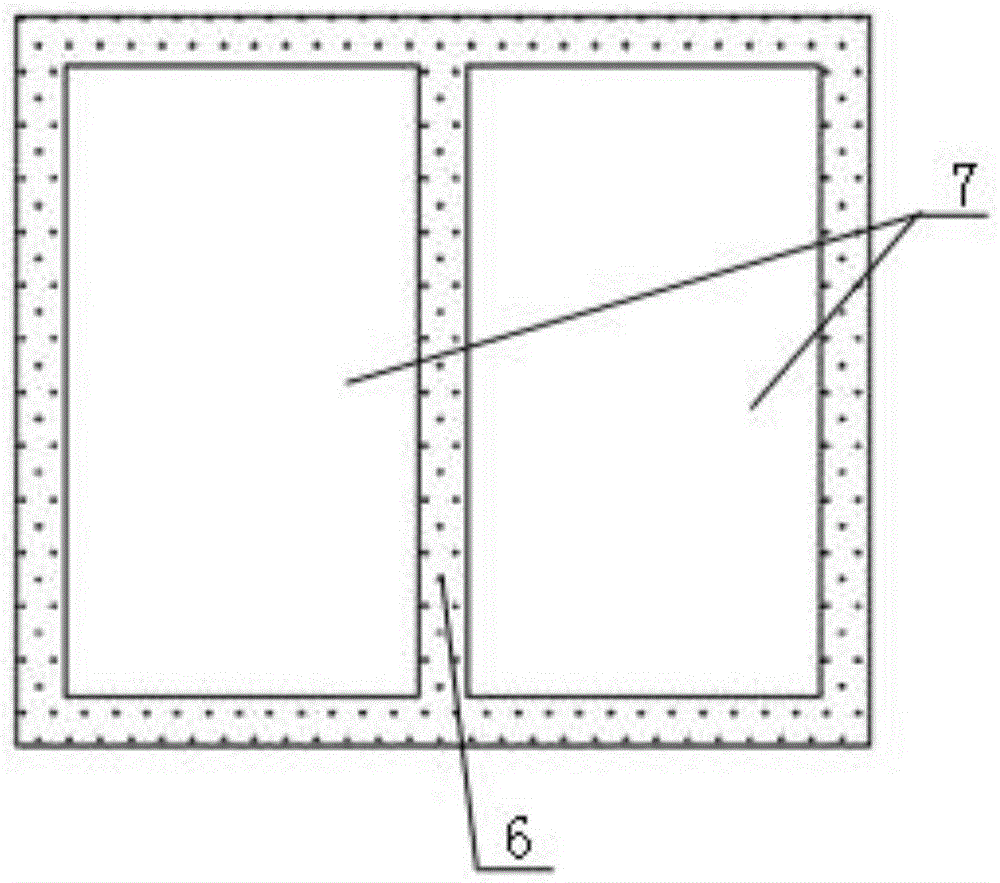

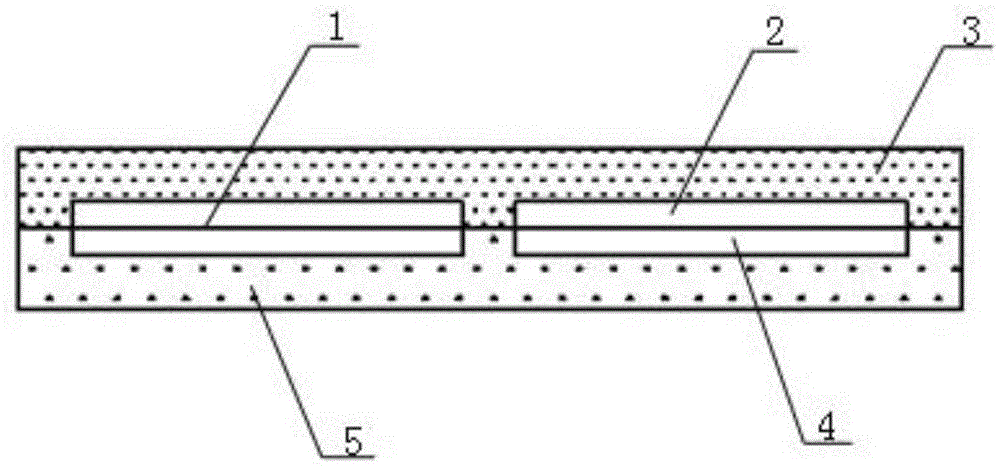

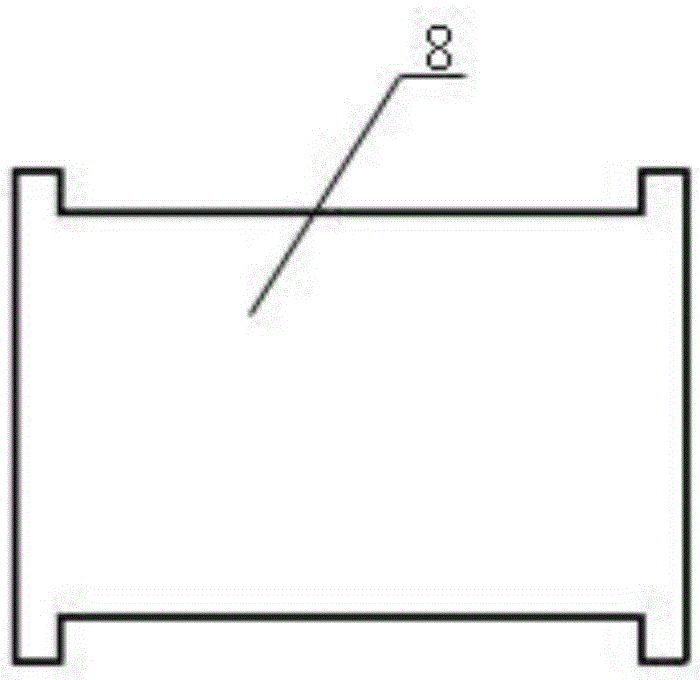

[0044] [Example 1] The manufacturing process of a hollow insulation riser with a partition is as follows:

[0045] Make working layer 5 material; Composite binder, organic fiber, Al 2 o 3 Sintering agent and mullite are added to the sand mill in the following parts by weight, 5 parts of composite binder; 6 parts of organic fiber; Al 2 o 3 5 parts of sintering agent; 84 parts of mullite; the order of addition is: first add sintering agent, composite binder and mullite, pre-mix for 10 minutes, then add organic fiber and stir for 15 minutes;

[0046] Make the insulation layer 3 material: add composite binder, organic fiber, clay clinker and floating beads to the sand mill in the following parts by weight, 8 parts of composite binder; 12 parts of organic fiber; 77 parts of clay clinker; 3 parts of floating beads parts; the order of addition is: first add composite binder, clay clinker and floating beads, pre-mix for 10 minutes, then add organic fiber and stir for 15 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com