Tubular casting and production process thereof

A preparation process and casting technology, which is applied in the field of tubular castings and its preparation process, can solve problems such as difficult to achieve target product consistency, unfixed casting cavity, and inferior product quality, so as to optimize processing performance and use characteristics, The effect of light weight and reduced product scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

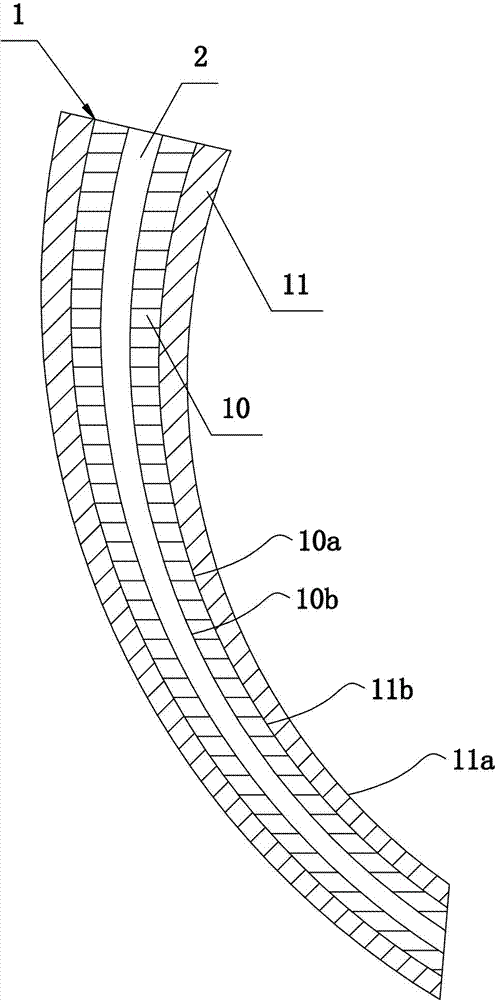

[0025] Embodiment 1: the casting pipe 10 is an aluminum alloy casting pipe 10 , and the die-casting pipe 11 is a magnesium alloy die-casting pipe 11 . The manufacturing process of the tubular casting of this structure comprises the following steps:

[0026] In the first step, according to the specific shape and size of the target casting, the casting simulation model is designed through computer simulation software, and then the die-casting mold is made according to the casting simulation model.

[0027] In the second step, the following raw materials are made into a liquid melt: by mass percentage, silicon 5%, zinc 3%, magnesium 0.3%, copper 2%, iron 0.1%, manganese 1%, titanium 0.1%, aluminum 88.5%; after being released from the furnace, the molten solution is cast into a casting mold with a sand core, the resulting casting is demolded, and a casting tube 10 is formed after the casting is cooled, and then the casting tube 10 is placed in the first The corresponding position...

Embodiment 2

[0032]Embodiment 2: The casting pipe 10 is an aluminum alloy casting pipe 10 , and the die-casting pipe 11 is an aluminum alloy die-casting pipe 11 . The manufacturing process of the tubular casting of this structure comprises the following steps:

[0033] In the first step, according to the specific shape and size of the target casting, the casting simulation model is designed through computer simulation software, and then the die-casting mold is made according to the casting simulation model.

[0034] In the second step, the following raw materials are made into a liquid melt: by mass percentage, silicon 5%, zinc 3%, magnesium 0.3%, copper 2%, iron 0.1%, manganese 1%, titanium 0.1%, aluminum 88.5%; after being released from the furnace, the molten solution is cast into a casting mold with a sand core, the resulting casting is demolded, and a casting tube 10 is formed after the casting is cooled, and then the casting tube 10 is placed in the first The corresponding position ...

Embodiment 3

[0037] Embodiment 3: The casting pipe 10 is a magnesium alloy casting pipe 10 , and the die-casting pipe 11 is an aluminum alloy die-casting pipe 11 . The manufacturing process of the tubular casting of this structure comprises the following steps:

[0038] In the first step, according to the specific shape and size of the target casting, the casting simulation model is designed through computer simulation software, and then the die-casting mold is made according to the casting simulation model.

[0039] In the second step, the following raw materials are made into a liquid melt: by mass percentage, aluminum 3%, zinc 2%, titanium 0.1%, manganese 0.9%, magnesium 94%; Place the casting mold with the sand core, demold the obtained casting, and form a casting tube 10 after the casting is cooled, and then put the casting tube 10 in the corresponding position of the die-casting mold made in the first step, The die-casting mold is then installed on the die-casting machine.

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com