Method for preparing microporus, high-activity and low-density calcium silicate

A calcium silicate, high activity technology, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of poor quality, high filler impurity content, low calcium silicate activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

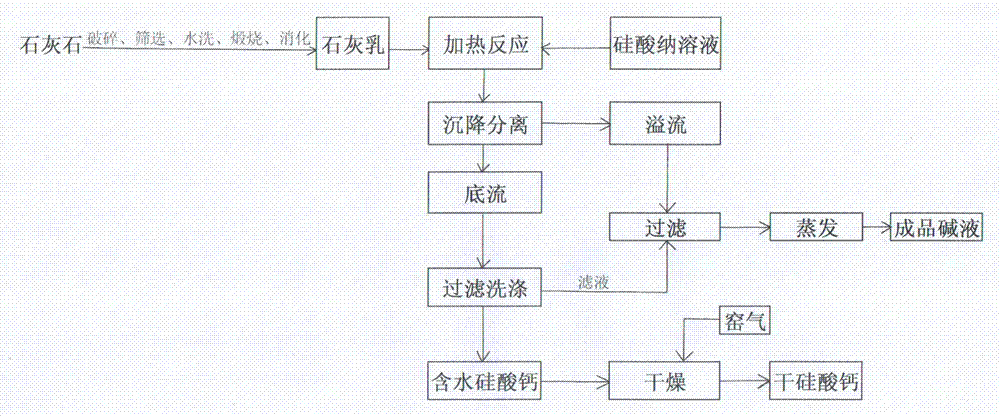

Image

Examples

Embodiment Construction

[0016] A method for preparing microporous high-activity low-density calcium silicate. The raw materials are milk of lime and sodium silicate solution, and the molar mass of the milk of lime (in terms of CaO concentration) and sodium silicate solution (in terms of SiO2 concentration) The ratio is CaO / SiO2: 0.95~1.05, and the preparation method steps are as follows:

[0017] (1) Crushing: Put the limestone raw material into the crusher for crushing;

[0018] (2) Screening and washing: place the crushed limestone in a sieve with a pore size of 5 cm for screening, and wash the screened limestone with water at the same time;

[0019] (3) Calcination: place the screened and washed limestone in a vertical kiln for calcination, the calcination temperature is 1200°C, and the calcination time is 5 hours to produce quicklime (CaO) and carbon dioxide (CO2);

[0020] (4) Digestion: add quicklime generated by calcining limestone into hot water, the ratio of quicklime to hot water is 1:6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com