Continuous potassium nitrate production system combined with liquid ammonium nitrate production

A liquid ammonium nitrate production system technology, applied in the field of chemical production, can solve the problems of high energy consumption, low concentration of ammonium nitrate solution, and undisclosed production process of ammonium nitrate solution, and achieve high concentration, avoid explosion hazard, and low pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

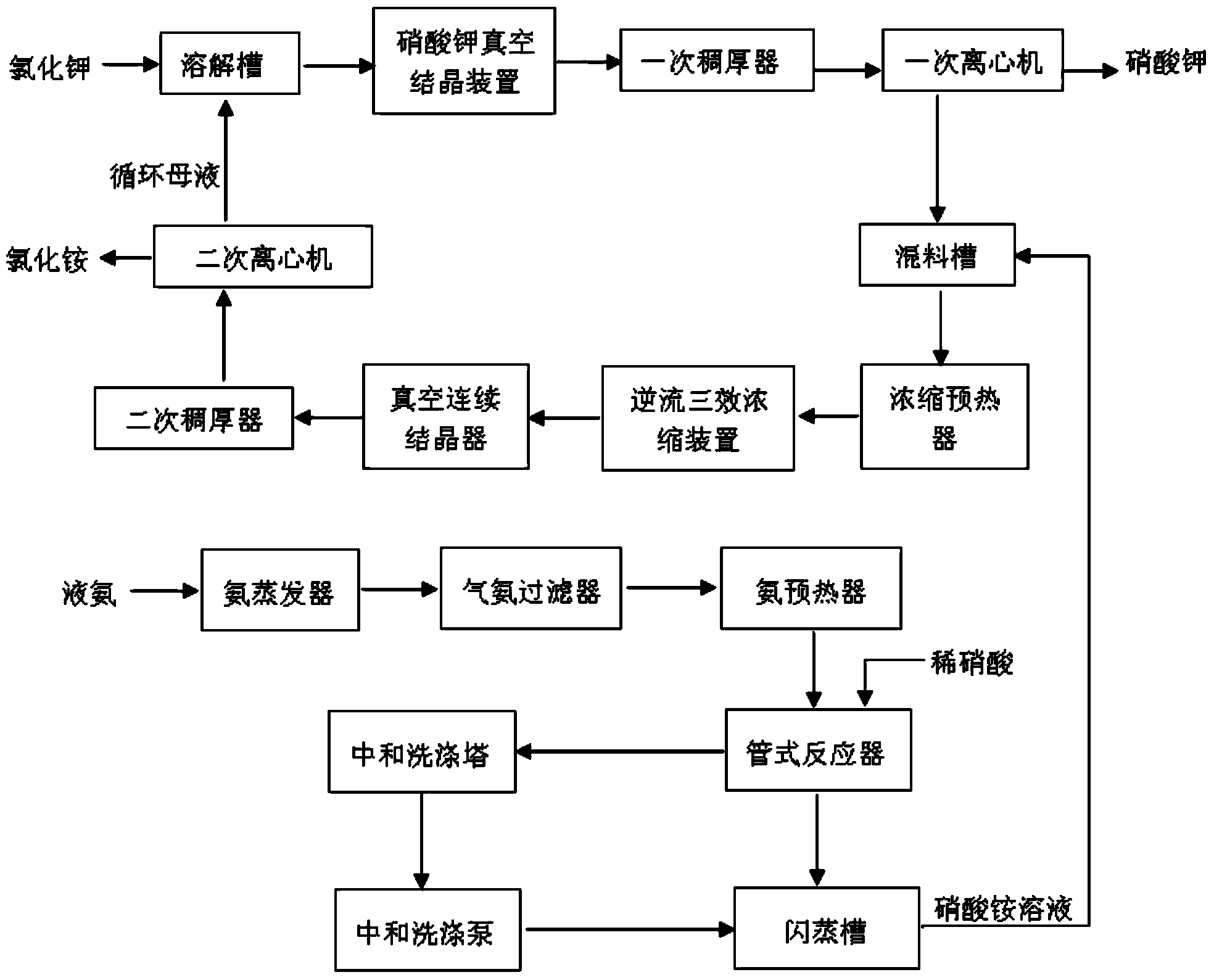

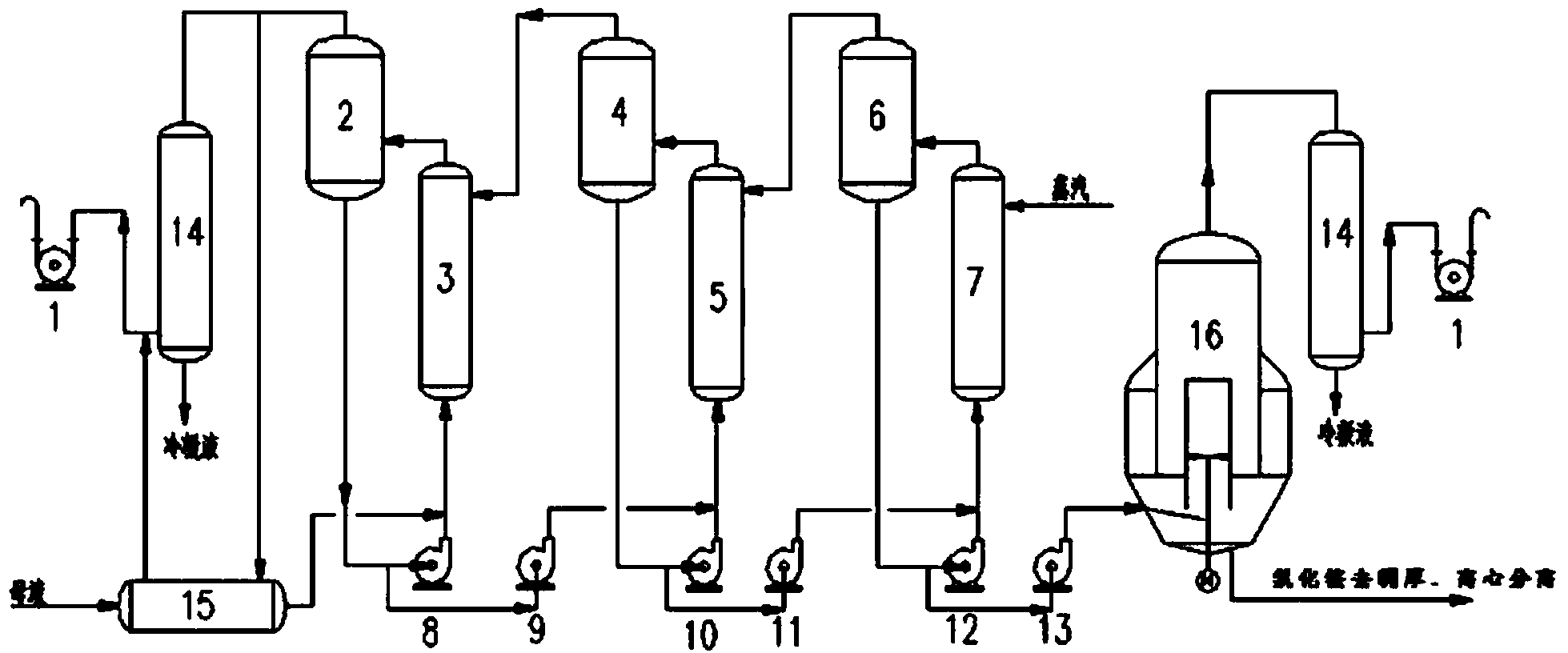

[0052] A continuous potassium nitrate production system combined with liquid ammonium nitrate production, comprising a potassium nitrate production system and a liquid ammonium nitrate production system, the potassium nitrate production system comprising a dissolution tank, a potassium nitrate vacuum crystallization device, and a primary thickener , a centrifuge, a mixing tank, a concentration preheater, a countercurrent three-effect concentration device, a vacuum continuous crystallizer, a secondary thickener and a secondary centrifuge; the outlet of the dissolution tank and the potassium nitrate vacuum crystallization device The feed port of the potassium nitrate vacuum crystallization device is connected with the feed port of the primary thickener, the discharge port of the primary thickener is connected with the feed port of the primary centrifuge, and the primary centrifuge The liquid discharge port of the liquid is connected with the feed port of the mixing tank, the disc...

Embodiment 2

[0059] Utilize the method for the continuous production of potassium nitrate of the continuous potassium nitrate production system combined with the production of liquid ammonium nitrate described in embodiment 1, the steps are as follows:

[0060] (1) Add circulating mother liquor, water and Potassium Chloride in dissolving tank, mix evenly, steam is heated to 75 ℃ and dissolves, and makes mixed solution, and described circulating mother liquor is ammonium chloride mother liquor, and ammonium ion and chlorine in mixed solution The molar ratio of ions is 1:1,

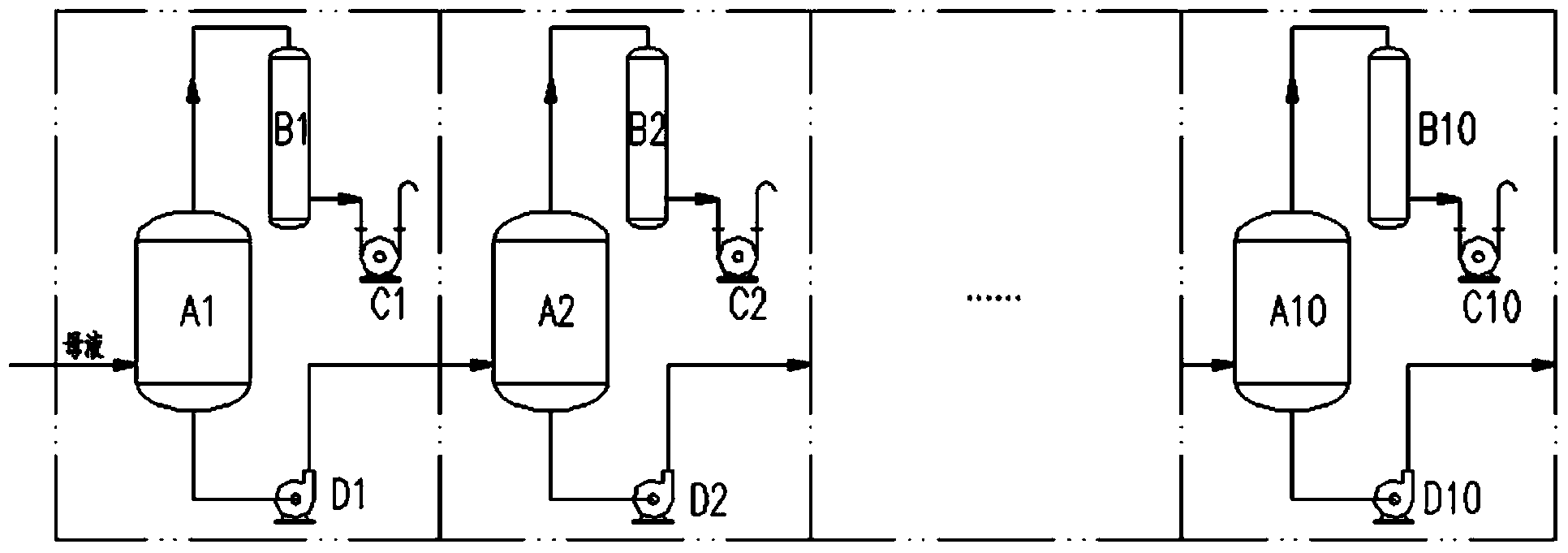

[0061] (2) mixed solution enters potassium nitrate vacuum crystallization device successively, and potassium nitrate vacuum crystallization device is the device of 6 grades of series structure; 55°C, vacuum degree is 0.018MPa, the temperature of the third stage vacuum crystallizer is 42°C, the vacuum degree is 0.010MPa, the temperature of the fourth stage vacuum crystallizer is 35°C, the vacuum degree is 0.003MPa, the t...

Embodiment 3

[0066] Utilize the method for the continuous production of potassium nitrate of the continuous potassium nitrate production system combined with the production of liquid ammonium nitrate described in embodiment 1, the steps are as follows:

[0067] (1) Add circulating mother liquor, water and Potassium Chloride in dissolving tank, mix evenly, steam is heated to 80 ℃ and dissolves, and makes mixed solution, and described circulating mother liquor is ammonium chloride mother liquor, and ammonium ion and chlorine in mixed solution The molar ratio of ions is 1:1.1,

[0068] (2) mixed solution enters potassium nitrate vacuum crystallization device successively, and potassium nitrate vacuum crystallization device is the device of 6 grades of series structure; 60°C, vacuum degree is 0.015MPa, the temperature of the third stage vacuum crystallizer is 45°C, the vacuum degree is 0.008MPa, the temperature of the fourth stage vacuum crystallizer is 38°C, the vacuum degree is 0.004MPa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com