A functional nanometer material/metal-organic framework composite and a preparing method thereof

A metal-organic framework and functional nanotechnology, which is applied in copper-organic compounds, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of low production efficiency, harsh reaction conditions, and long time consumption, and achieve high production efficiency, Good dispersing effect and anti-loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Ferritin / metal organic framework complex

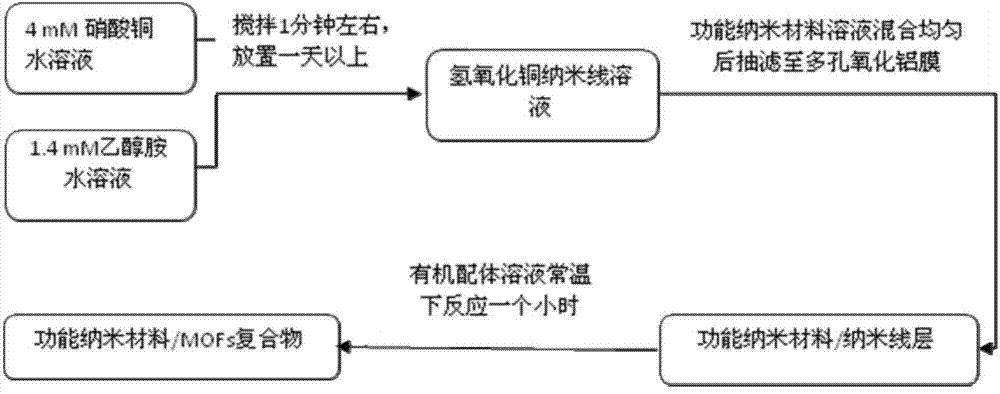

[0035] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate. After 1 minute, slow down the stirring speed, and seal the reaction vessel. After 24 hours, a copper hydroxide nanowire solution is obtained.

[0036] 2) Mix 30ml of copper hydroxide nanowire solution and 0.5ml of ferritin solution of 1mg / ml and filter to form a 300nm thick ferritin / copper hydroxide nanowire layer on the porous alumina membrane. The diameter of the membrane is 2.5cm, the pore diameter is 200nm, and the porosity is 25-50%;

[0037] 3) Add the ferritin / copper hydroxide nanowire layer to 10ml, the concentration is 5mM, the solvent is the trimesic acid solution of ethanol water, the volume ratio of ethanol and water in the ethanol water solution is 1:1, and react at room temperature 1 hour to obtain ferritin / metal organic framework complex.

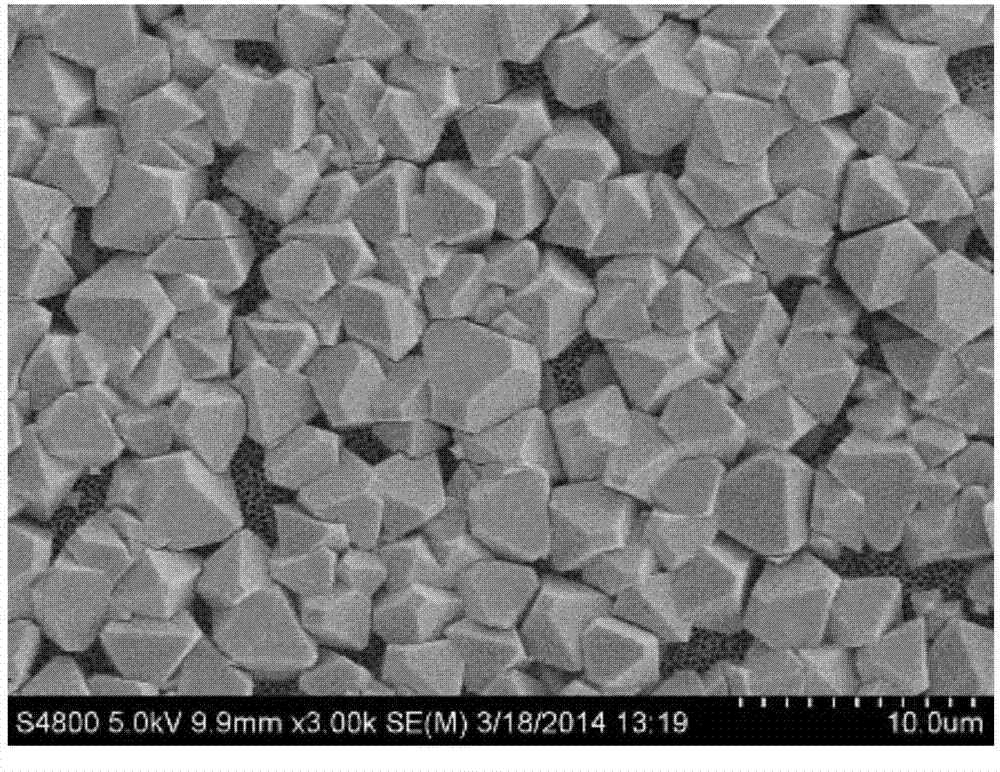

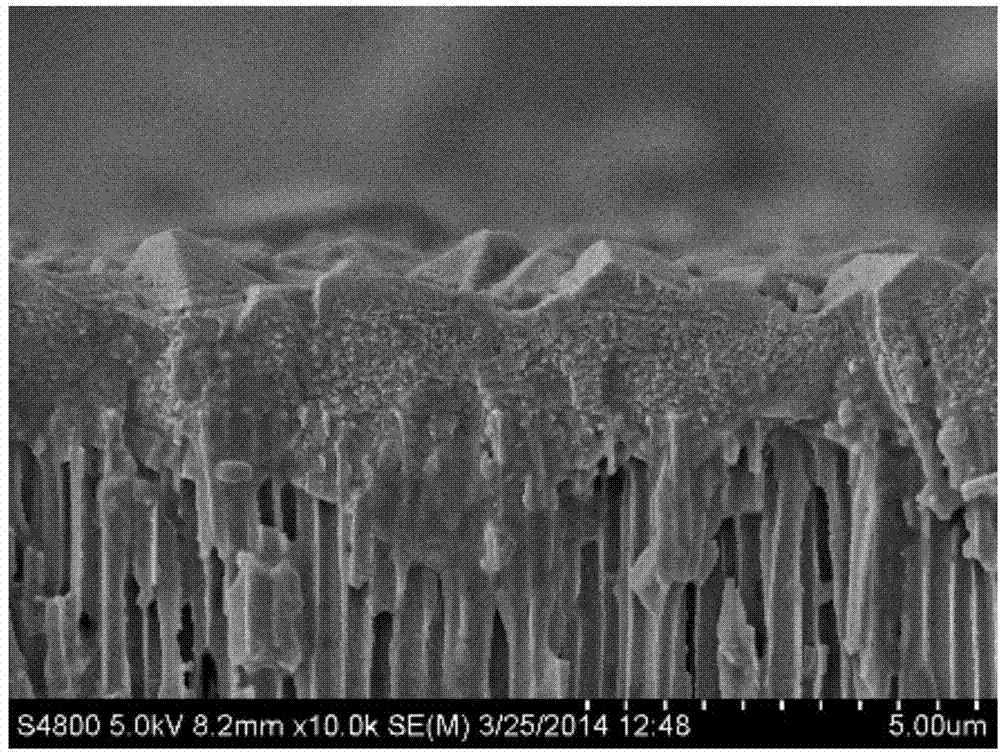

[0038] figure 2 and 3 The SEM images of the...

Embodiment 2

[0039] Example 2 Glucose oxidase / metal organic framework complex

[0040] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate, after 1 minute, slow down the stirring speed, and seal the reaction vessel, and obtain a copper hydroxide nanowire solution after 24 hours.

[0041] 2) Mix 30ml of copper hydroxide nanowire solution and 0.5ml of glucose oxidase at 1mg / ml and filter to form a 300nm thick glucose oxidase / copper hydroxide nanowire layer on the porous aluminum oxide membrane. The diameter of the aluminum film is 2.5cm, the pore diameter is 200nm, and the porosity is 25-50%;

[0042] 3) Add the glucose oxidase / copper hydroxide nanowire layer to 10ml, the concentration is 5mM, and the solvent is the trimesic acid solution of ethanol water. The volume ratio of ethanol to water in the ethanol water solution is 1:1. React for 1 hour to obtain the glucose oxidase / metal organic framework complex.

[0043] Figure 5 and ...

Embodiment 3

[0044] Example 3 Single-walled carbon nanotube / metal organic framework composite

[0045] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate, after 1 minute, slow down the stirring speed, and seal the reaction vessel, and obtain a copper hydroxide nanowire solution after 24 hours.

[0046] 2) Mix 0.5ml of the single-walled carbon tube solution containing copper hydroxide nanowire solution 30ml and 1mg / ml evenly and filter to form a 300nm thick single-wall carbon tube / copper hydroxide nanowire layer on the porous alumina membrane , the diameter of the porous alumina membrane is 2.5cm, the pore diameter is 200nm, and the porosity is 25-50%;

[0047]3) Add the single-wall carbon tube / copper hydroxide nanowire layer to 10ml, the concentration is 5mM, and the solvent is ethanol water in the trimesic acid solution. The volume ratio of ethanol to water in the ethanol water solution is 1:1. The single-walled carbon nanotube / me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com