Flame-retardant block copolymer containing nitrogen and phosphorus and preparation method thereof

A technology of block copolymers and polymer chains, which is applied in the field of polymer halogen-free flame retardants, can solve the problems of restricting the widespread use of halogen-containing flame retardants, achieve improved compatibility and flame retardancy, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

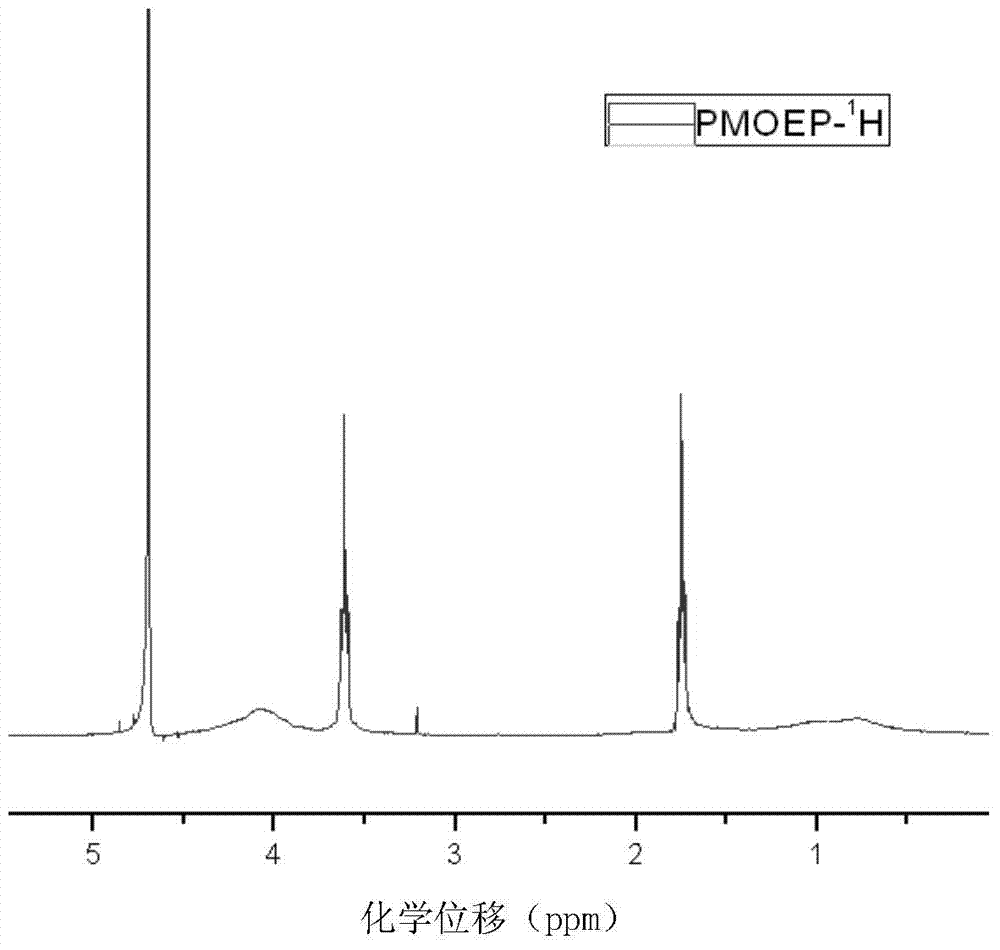

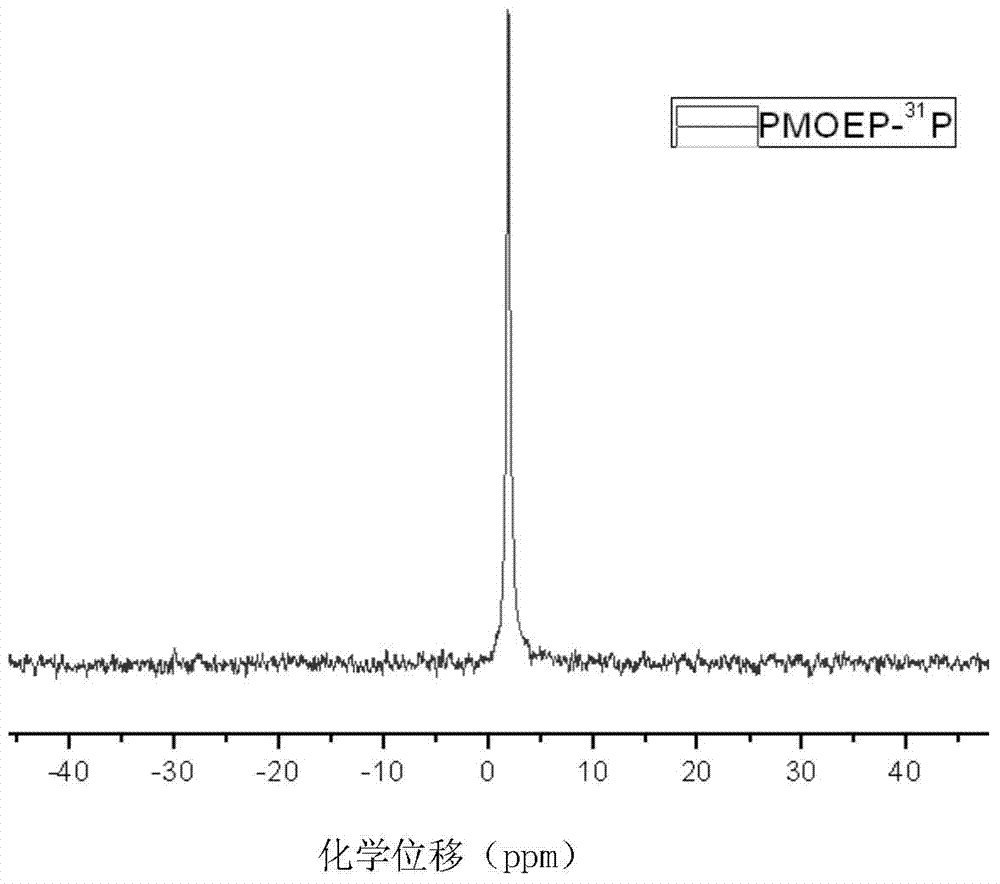

[0028] (1) PMOEP 80 Synthesis of Macromolecular Chain Transfer Agents

[0029] Dissolve MOEP (0.9125g, 4mmol), CDB (13.62mg, 0.05mmol) and AIBN (1.64mg, 0.01mmol) in 5ml of anhydrous methanol, after continuous freeze-thaw degassing for 3 to 5 times, under the protection of argon Polymerize at 65°C. After 24 hours of reaction, stop the reaction by quenching with liquid nitrogen. Use 15 times the volume, that is, 90ml of ethanol as the precipitant, and repeat the precipitation twice to obtain the product PMOEP. 80 .

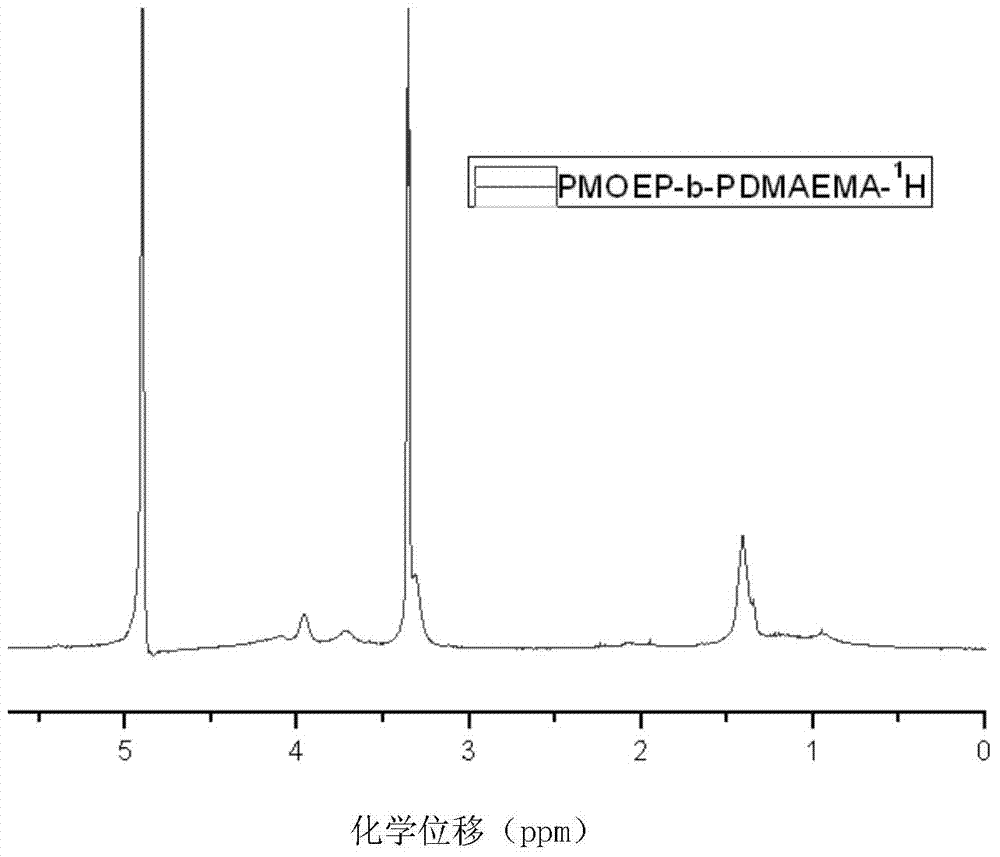

[0030] (2) PMOEP 80 -b-PDMAEMA 100 Synthesis of diblocks

[0031] will PMOEP 80 (0.3g, 0.03mmol), DMAEMA (0.6027ml, 3mmol), AIBN (1mg, 0.006mmol) were dissolved in 3ml of anhydrous methanol, after continuous freeze-thaw degassing for 3 to 5 times, under the protection of argon at 65°C Polymerization, after 24 hours of reaction, it was quenched with liquid nitrogen to stop the reaction, and ethanol was used as the precipitating agent for repeated precipitation...

Embodiment 2

[0033] (1) PMOEP 60 Synthesis of Macromolecular Chain Transfer Agents

[0034] Dissolve MOEP (0.6844g, 3mmol), CDB (13.62mg, 0.05mmol) and AIBN (1.64mg, 0.01mmol) in 4.5ml of anhydrous methanol. Polymerization at 65°C, after 24 hours of reaction, quenched with liquid nitrogen to stop the reaction, 15 times the volume, that is, 80ml of ethanol as the precipitant, and repeated precipitation twice to obtain the product PMOEP 60 .

[0035] (2) PMOEP 60 -b-PDMAEMA 100 Synthesis of diblocks

[0036] will PMOEP 60 (0.225g, 0.0225mmol), DMAEMA (0.6027ml, 3mmol), AIBN (1mg, 0.006mmol) were dissolved in 3ml of anhydrous methanol, after continuous freeze-thaw degassing for 3 to 5 times, under argon protection at 65°C Polymerization, after 24 hours of reaction, it was quenched with liquid nitrogen to stop the reaction, and ethanol was used as the precipitating agent for repeated precipitation twice to obtain the product PMOEP 60 -b-PDMAEMA100 .

Embodiment 3

[0038] (1) PMOEP 80 Synthesis of Macromolecular Chain Transfer Agents

[0039] Dissolve MOEP (0.9125g, 4mmol), CDB (13.62mg, 0.05mmol) and AIBN (1.64mg, 0.01mmol) in 4.5ml of anhydrous methanol. Polymerization at 65°C, after 24 hours of reaction, quenched with liquid nitrogen to stop the reaction, 15 times the volume, that is, 80ml of ethanol as the precipitant, and repeated precipitation twice to obtain the product PMOEP 80 .

[0040] (2) PMOEP 80 -b-PDMAEMA 80 Synthesis of diblocks

[0041] will PMOEP 80 (0.3g, 0.03mmol), DMAEMA (0.4822ml, 2.4mmol), AIBN (1mg, 0.006mmol) were dissolved in 3ml of anhydrous methanol, after continuous freeze-thaw degassing for 3 to 5 times, under the protection of argon at 65 Polymerization at ℃, after 24 hours of reaction, it was quenched with liquid nitrogen to stop the reaction, and ethanol was used as the precipitating agent for repeated precipitation twice to obtain the product PMOEP 80 -b-PDMAEMA 80 .

[0042] Obtained target pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com