Rubber composition and tire same

A rubber composition and diene rubber technology, applied in the field of tire rubber, can solve the problems such as failure to provide the volume resistivity of tire compound rubber, and achieve the effects of reducing volume resistivity, improving thermal conductivity, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0144] The following table 1-2 shows the composition of the rubber composition prepared according to the above mixing method, and the performance of the test, surface modified carbon nanotubes (modified group is cyclopentadiene and its polymer) Performance comparison with carbon black and non-surface-modified carbon nanotubes:

[0145] Table 1 (surface-modified carbon nanotubes have carried out performance comparison with the carbon black of same addition, wherein composition 1-1, 1-2, 1-3, 1-4 are as comparison)

[0146]

[0147] It can be seen from Table 1 above:

[0148] 1) Surface-modified carbon nanotubes can overcome the shortcomings of poor dispersion and difficult processing. It has the same Mooney viscosity as carbon black, and its tensile strength, tear strength, and wear resistance are all better than carbon with the same amount. Black is better.

[0149] 2) The hysteresis loss of surface-modified carbon nanotubes is the same as that of carbon black with the sa...

Embodiment 3-5

[0159] The following table 3-5 shows the composition of the rubber composition prepared according to the above-mentioned mixing method, and the performance of the test, by changing the surface modified carbon nanotube (modified group is cyclopentadiene and its multipolymer ) to compare with the reference formulation without adding carbon nanotubes.

[0160] Table 3 (wherein 3-1 is a reference formula, and all the other are experimental implementation formulas)

[0161]

[0162]

[0163] Table 4 (wherein 4-1 is a reference formula, and all the other are experimental implementation formulas)

[0164]

[0165] Table 5 (wherein 5-1 is a reference formula, and all the other are experimental implementation formulas)

[0166]

[0167] Can further find out from above table 3-5: for the situation of 30-110 parts by weight of white carbon black consumption and 3-40 parts by weight of carbon black consumption, add cyclopentadiene and polymer surface modification thereof The...

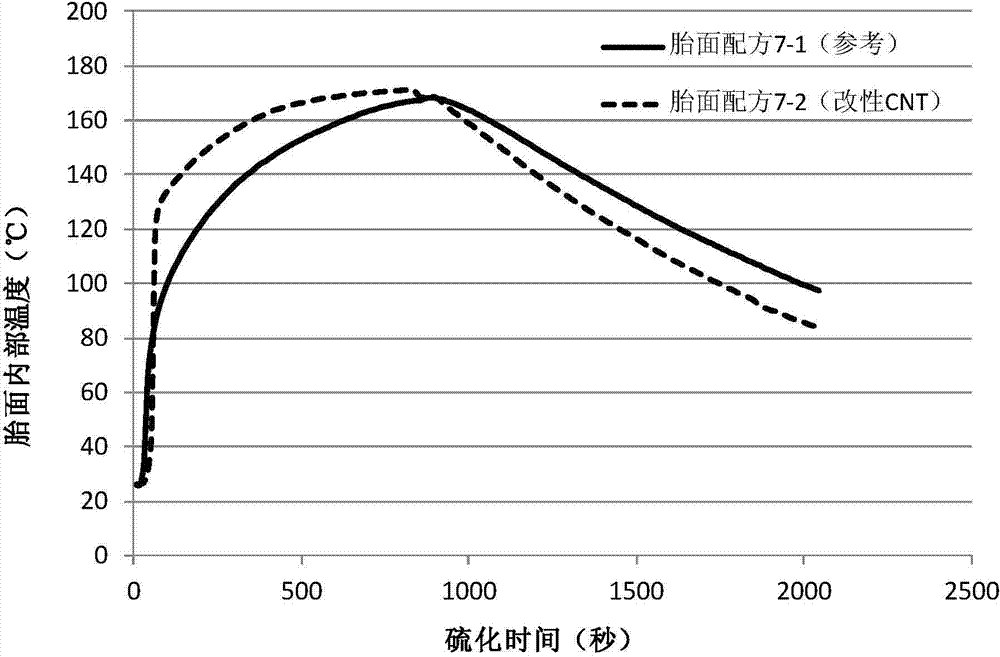

Embodiment 6

[0169] The following table 6 shows the composition of the rubber composition prepared according to the above mixing method, and the performance of the test. Table 6 is a comparison between carbon nanotubes modified by various modifying groups, wherein composition 6 -1, 6-2, 6-3, 6-4, 6-5 for comparison:

[0170] Table 6

[0171]

[0172] It can be seen from Table 6 above that:

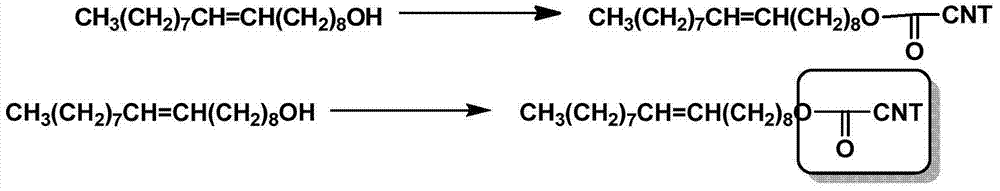

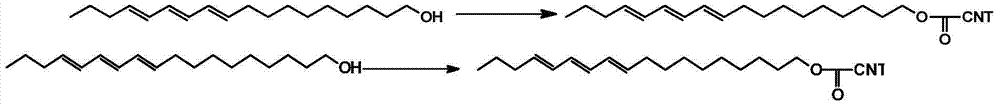

[0173] After adding cyclopentadiene and its polymers, surface modified carbon nanotubes with hydroxyl groups, the Mooney viscosity and hardness increased, while adding long-chain aliphatic hydrocarbon surface-modified carbon nanotubes, the Mooney viscosity and hardness decreased, and the long-chain Although aliphatic hydrocarbon modified carbon nanotubes can improve its compatibility with rubber and its dispersion in rubber, but the longer organic molecular chains hinder the contact bridging of carbon nanotubes, thereby reducing the conductivity of the rubber compound. performance. The dispersibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com