Water-soluble crude oil desulfurizing agent and preparation method thereof

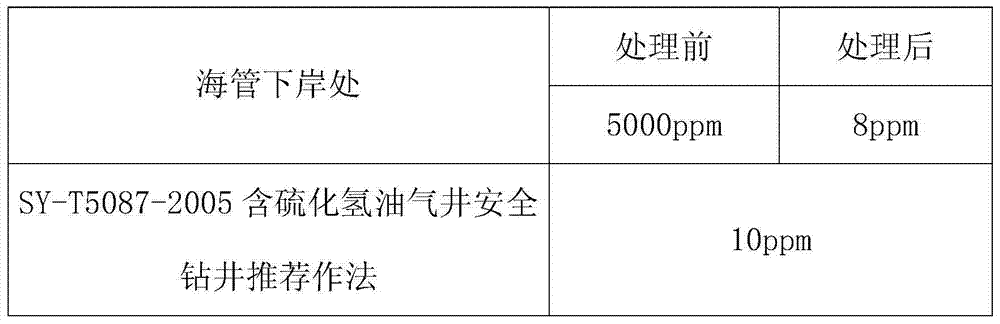

A desulfurizer, water-soluble technology, applied in the field of water-soluble crude oil desulfurizer and its preparation, can solve the problems of poor desulfurization effect and low sulfur capacity, and achieve the effect of excellent instantaneous desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A water-soluble crude oil desulfurizer, using water as solvent, solute: formaldehyde, mass fraction 10%; methyldiethanolamine (MDEA), mass concentration 7%; diethanolamine (DEA), mass concentration 32.8%; sodium nitrite , The mass concentration is 6%.

Embodiment 2

[0024] A water-soluble crude oil desulfurizer, using water as solvent, solute: formaldehyde, mass fraction 15%; methyldiethanolamine (MDEA), mass concentration 20%; diethanolamine (DEA), mass concentration 34%; sodium nitrite , The mass concentration is 7%.

Embodiment 3

[0026] A preparation method of a water-soluble crude oil desulfurizer, the preparation process includes the following steps:

[0027] Step 1: Take 60g of sodium nitrite and dissolve it in 1000ml of water to prepare a sodium nitrite solution;

[0028] Step 2: Drop 8ml of diethanolamine into 200ml of methyldiethanolamine, and place it in a refrigerator at 4°C for 48 hours after the titration;

[0029] Step 3: Prepare 30ml of 20% formaldehyde solution in the dark and save it for later use, and then add it to the cooled mixed solution;

[0030] Step 4: Place the methyldiethanolamine, formaldehyde solution and diethanolamine solution in a shaker, shake for 70min and take it out.

[0031] Add the corresponding amount of sodium nitrite solution prepared in step 1 according to the mass concentration of sodium nitrite in the final desulfurizer, and adjust the concentration with distilled water during the process;

[0032] Step 5: The mixed solution after standing for 24 hours is the prepared desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com