Recycled concrete L-shaped steel tube special-shaped column

A technology of recycled concrete and special-shaped columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of low uniaxial compressive strength, easy occurrence of micro-cracks, affecting popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

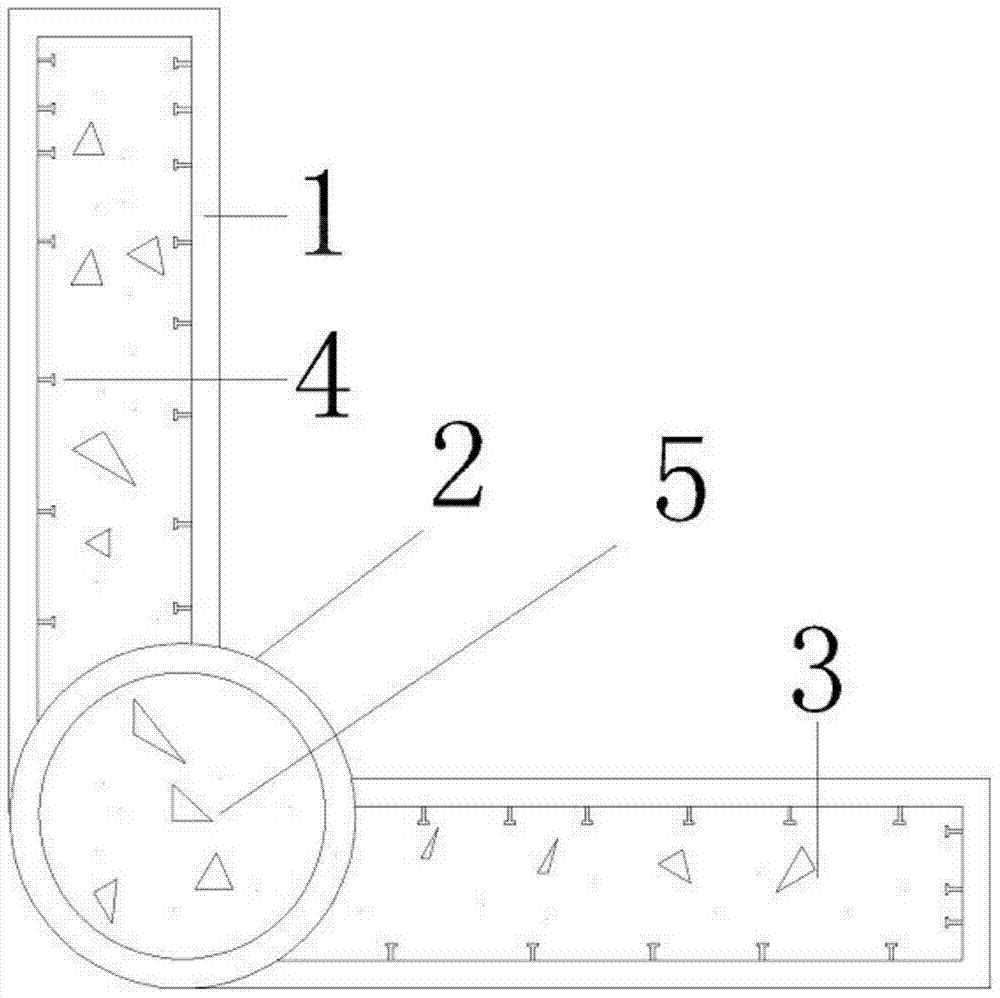

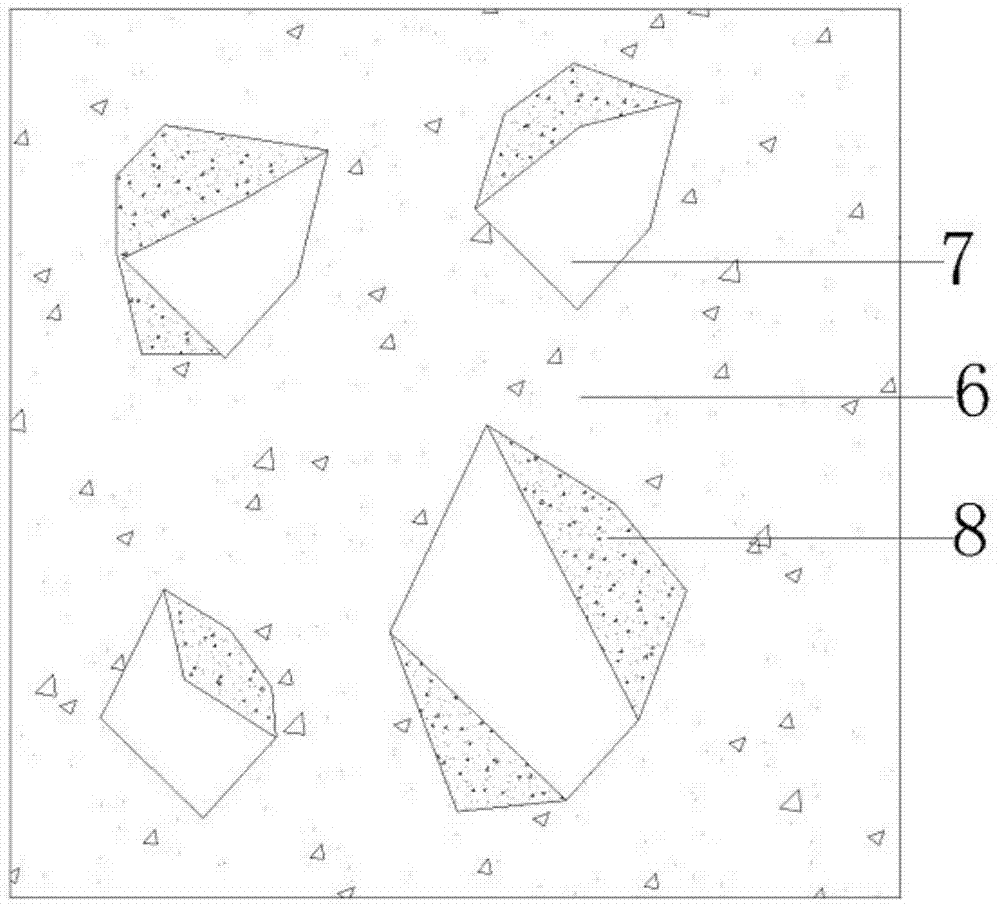

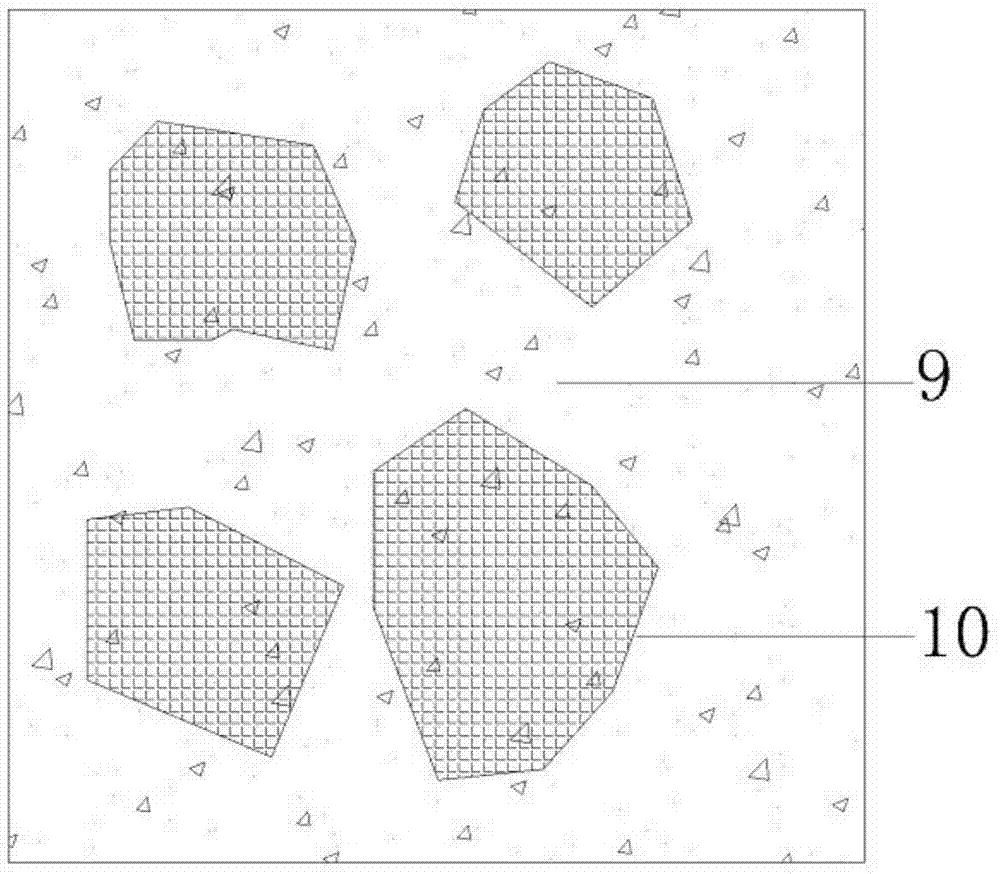

[0017] Such as Figures 1 to 3 As shown, the recycled concrete L-shaped steel pipe special-shaped column of the present invention includes an L-shaped special-shaped column, and the L-shaped special-shaped column is formed by welding a circular steel pipe 2 and two U-shaped steel channels 1, and the circular steel pipe is used as the corner of the L-shaped special-shaped column The two U-shaped steel channels are used as the two limbs of the L-shaped special-shaped column; ordinary aggregate concrete 3 is poured inside the U-shaped steel channel, and recycled aggregate concrete 5 is poured inside the circular steel pipe; the U-shaped steel channel is welded with shear Bolt 4, the diameter of the circular steel pipe is not less than 1.2 times the width of the U-shaped steel channel.

[0018] Production process

[0019] The U-shaped steel channel is welded by outsourcing steel plates. First, several rows of shear bolt connectors are welded on the steel plate, and then the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com