All-fiber temperature sensor based on fiber core mismatch attenuators

A temperature sensor and fiber core mismatch technology, which is applied in the field of optical fiber sensor manufacturing, can solve the problems of complex production of all-fiber temperature sensors, and achieve the effects of avoiding the influence of cross-sensitivity, good repeatability, high accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation plan is as follows:

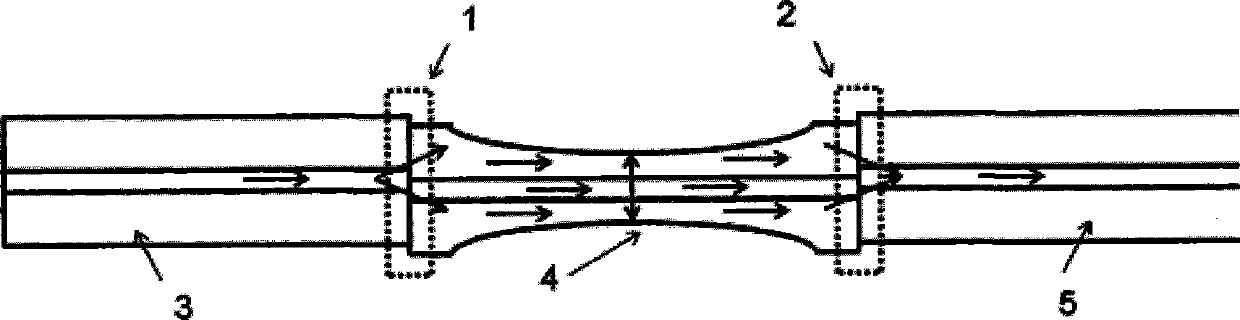

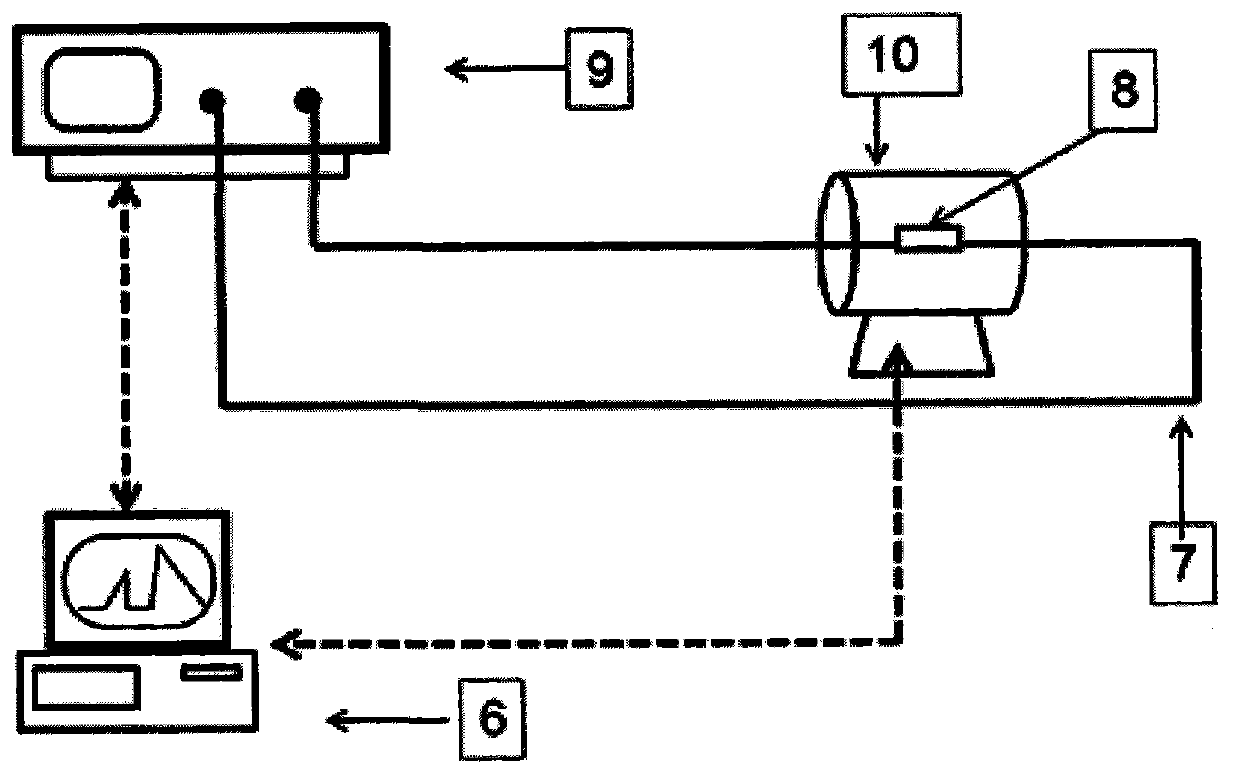

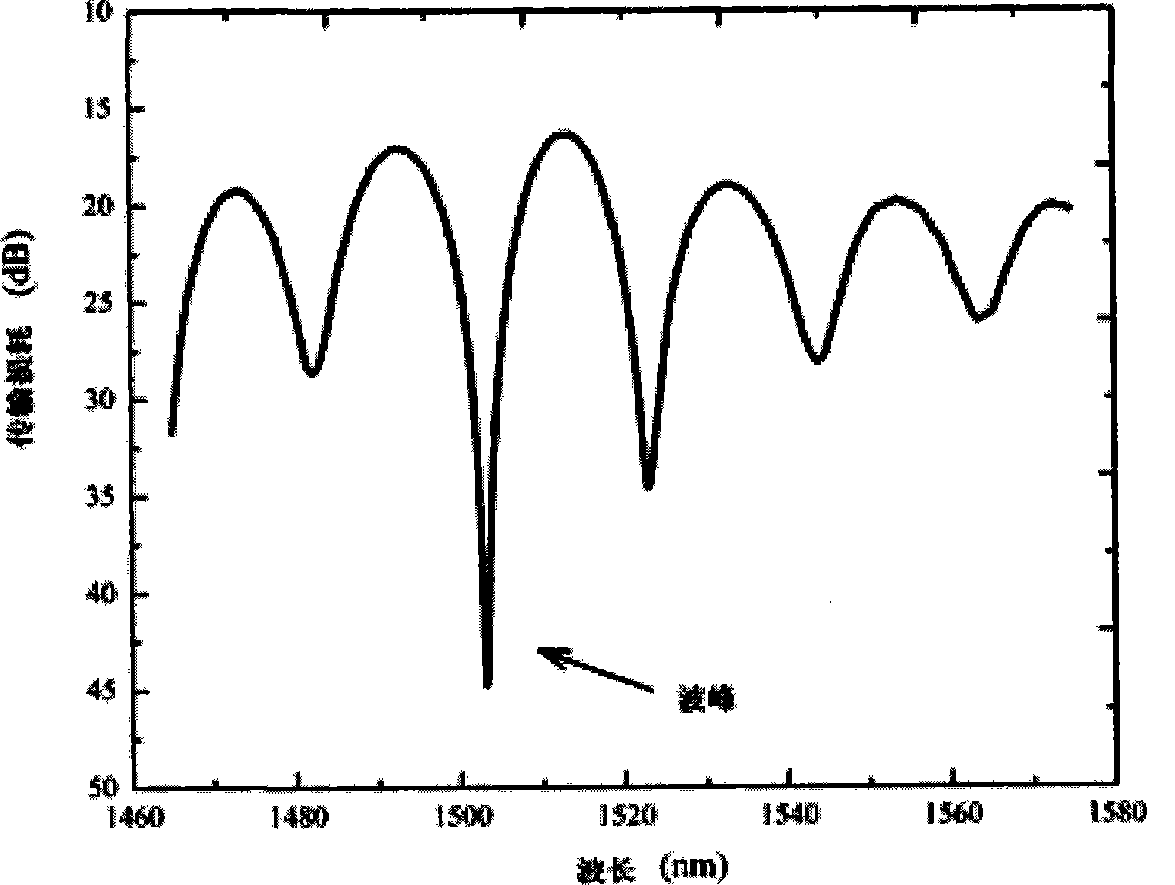

[0019] A new all-fiber high-sensitivity temperature sensor based on the principle of Mach-Zehnder interferometer realized by optical fiber fusion splicer and optical fiber taper machine. The specific implementation method mainly includes the preparation of the new sensing structure and the temperature test of the sensor. The optical fiber used in the manufacture and testing of the present invention is figure 1 Medium SM-28 fiber optic.

[0020] 1. Preparation of new sensing structures

[0021] The preparation process of the new sensing structure:

[0022] Step 1, take two single-mode optical fibers, remove the coating layer with stripping pliers, use a cleaver to cut the end faces flat, and then fix the two flattened fiber ends on the fiber fusion splicer, and set the splicing mode of the fiber fusion splicer to manual mode (set clean The discharge time is 100ms, the pre-melting discharge time is 110ms, the welding di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com