Processing method of concentrated sugarcane juice

A processing method and technology for concentrated juice, applied in the processing field of sugarcane juice concentrate, can solve the problems of clogging of membrane pores, browning during processing and storage, loss of flavor substances and nutrients, etc. Clear and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

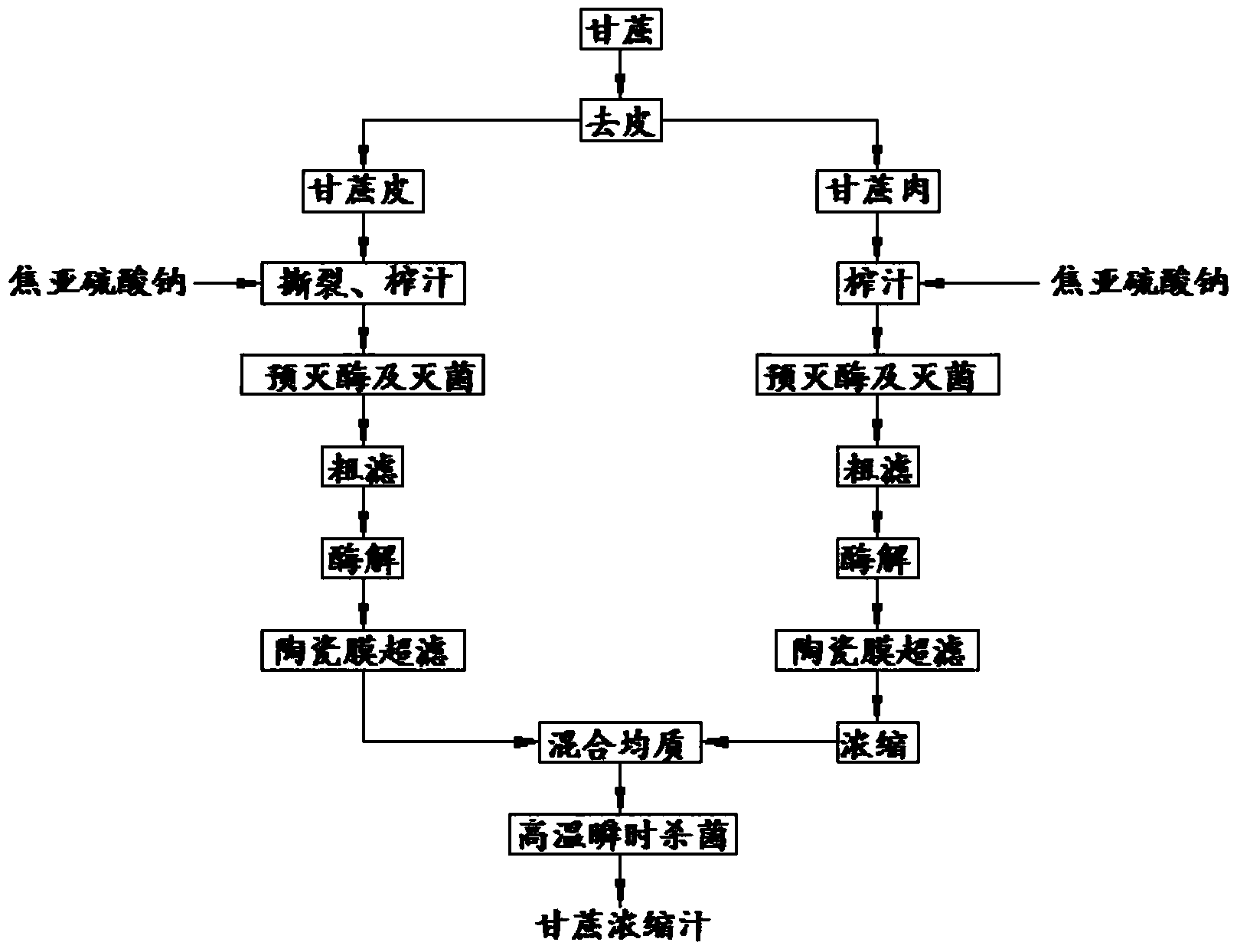

Image

Examples

Embodiment 1

[0034] A kind of processing method of sugarcane concentrated juice of the present invention, operation steps are:

[0035] (1) sugarcane peeling: select fresh and mature sugarcane, remove rotten, disease and pest raw materials, clean the surface of sugarcane and peel the skin to obtain sugarcane meat and sugarcane skin;

[0036] (2) Preparation of sugarcane meat concentrated juice

[0037] ① Juicing: Put the peeled sugarcane meat into the press to obtain a juice, spray water on the obtained bagasse, squeeze the juice again to obtain a second juice, mix the first juice with the second juice, and Add 85ppm of sodium metabisulfite (Na 2 S 2 o 5 ) to protect the color, to obtain the mixed juice of cane meat;

[0038] ② Pre-sterilization and enzyme deactivation: heat the mixed sugarcane meat juice to 95°C, keep it for 5 minutes, perform pre-sterilization and de-enzyme, so that part of the protein and colloid in the cane juice can be flocculated and precipitated to obtain heated...

Embodiment 2

[0051] (1) sugarcane peeling: select fresh and mature sugarcane, remove rotten, disease and pest raw materials, clean the surface of sugarcane and peel the skin to obtain sugarcane meat and sugarcane skin;

[0052] (2) Preparation of sugarcane meat concentrated juice

[0053] ① Juicing: put the peeled sugarcane meat into the press to extract a juice, spray water on the obtained bagasse, squeeze the juice again to obtain a second juice, mix the first juice with the second juice, and Add 95ppm of sodium metabisulfite (Na 2 S 2 o 5 ) to protect the color, to obtain the mixed juice of cane meat;

[0054] ② Pre-sterilization and enzyme deactivation: heat the mixed sugarcane meat juice to 98°C, keep it for 3 minutes, carry out pre-sterilization and de-enzyme, so that part of the protein and colloid in the sugarcane juice can be flocculated and precipitated to obtain heated cane meat juice;

[0055] ③Coarse filtration: the heated cane meat juice is first filtered through a scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com