Preparation method of (R)-propylene carbonate

A technology of propylene carbonate and acetic acid, which is applied in the direction of organic chemistry, can solve the problems of high production risk, high equipment requirements, and low yield, and achieve the effects of reduced production cost, high product yield, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

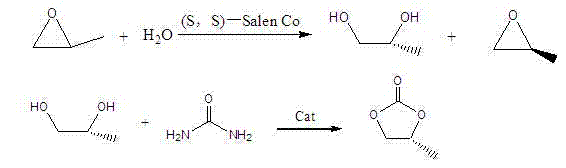

[0019] 1. Preparation of (R)-1,2-propanediol:

[0020] Weigh 0.002 mol (0.833g) of (S, S)-Salen Co catalyst into a 100 mL flask, add 18.4ml of toluene, then add 14.5mmol (0.87g) of AcOH, and then open to air and stir for 0.5h Activation of the catalyst. It can be seen that the reaction system gradually changes from brick red to dark brown, that is, the catalyst is activated. The toluene was then removed with a vacuum pump, leaving a dark brown solid, the activated catalyst.

[0021] Mix 40g of propylene oxide and 0.002mol of the activated catalyst in a flask, place the mixed system in an ice bath to 0-5°C, and slowly add 5.6g of water dropwise at the same time, then remove the ice bath, and then stir the reaction at room temperature 14 h. After the reaction, (S)-propylene oxide was distilled out under normal pressure, and then vacuum distillation was carried out with an oil pump to obtain 25.6 g of (R)-1,2 propanediol with a yield of 98%.

[0022] 2. Preparation of (R)-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com