Antistatic and antibacterial PE master batch and preparation method thereof

An antistatic and masterbatch technology, applied in the field of chemical modified material preparation, can solve the problems of insignificant antistatic and antibacterial effect, and achieve the effect of excellent antibacterial effect and good antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

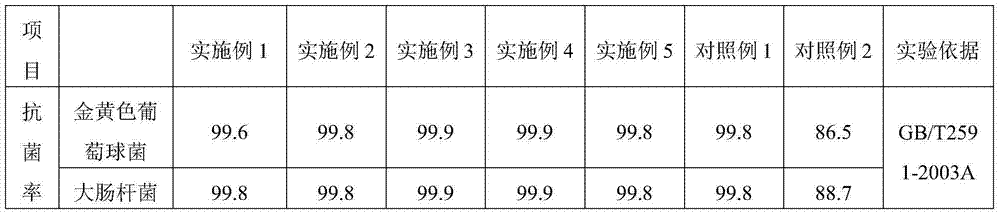

Examples

Embodiment 1

[0022] An antistatic and antibacterial PE masterbatch, comprising: 50 parts of PE, 1 part of barium stearate, 0.5 part of ethylene glycol lauramide, 1 part of paraffin, 5 parts of carbon black, 2-chloroethanesulfonic acid 0.2 parts of sodium, 10100.3 parts of antioxidant, 0.1 part of auxiliary antioxidant TNP, 3 parts of calcium carbonate, 1 part of propylene oxide, and 1 part of acrylamidopropyltrimethylammonium chloride.

[0023] The preparation method of above-mentioned antistatic antibacterial PE masterbatch, carry out according to the following steps:

[0024] Step 1: Add PE, diethanol lauramide, paraffin, carbon black, sodium 2-chloroethanesulfonate, propylene oxide and acrylamidopropyltrimethylammonium chloride into the reaction kettle and stir at 80°C 40 minutes, wherein stirring speed is 100 rev / min, obtains material one;

[0025] Step 2: Add mixture 1, barium stearate, antioxidant, auxiliary antioxidant and calcium carbonate to a high-speed kneader for kneading. The...

Embodiment 2

[0028] An antistatic and antibacterial PE masterbatch, comprising: 53 parts of PE, 2 parts of barium stearate, 0.6 part of ethylene glycol lauramide, 2 parts of paraffin, 7 parts of carbon black, 2-chloroethanesulfonic acid 0.6 parts of sodium, 1680.5 parts of antioxidant, 0.3 part of auxiliary antioxidant TNP, 5 parts of calcium carbonate, 2 parts of propylene oxide, 3 parts of acrylamidopropyltrimethylammonium chloride.

[0029] The preparation method of above-mentioned antistatic antibacterial PE masterbatch, carry out according to the following steps:

[0030] Step 1: Add PE, diethanol lauramide, paraffin, carbon black, sodium 2-chloroethanesulfonate, propylene oxide and acrylamidopropyltrimethylammonium chloride into the reaction kettle, and stir at 85°C 48 minutes, wherein stirring speed is 105 revs / min, obtains material one;

[0031] Step 2: Add mixture 1, barium stearate, antioxidant, auxiliary antioxidant and calcium carbonate to a high-speed kneader for kneading. Th...

Embodiment 3

[0034] An antistatic and antibacterial PE masterbatch, comprising: 55 parts of PE, 3 parts of barium stearate, 0.7 parts of ethylene glycol lauramide, 3 parts of paraffin, 8 parts of carbon black, 2-chloroethanesulfonic acid 0.7 parts of sodium, 10100.6 parts of antioxidant, 0.4 part of auxiliary antioxidant TNP, 6 parts of calcium carbonate, 3 parts of propylene oxide, 4 parts of acrylamidopropyltrimethylammonium chloride.

[0035] The preparation method of above-mentioned antistatic antibacterial PE masterbatch, carry out according to the following steps:

[0036] Step 1: Add PE, diethanol lauramide, paraffin, carbon black, sodium 2-chloroethanesulfonate, propylene oxide and acrylamidopropyltrimethylammonium chloride into the reaction kettle, and stir at 90°C 60 minutes, wherein the stirring speed is 110 rev / min, obtains material one;

[0037] Step 2: Add mixture 1, barium stearate, antioxidant, auxiliary antioxidant and calcium carbonate to a high-speed kneader for kneadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com