Electrostatic spraying method of anti-ultraviolet fabrics

An anti-ultraviolet and electrostatic spraying technology, which is applied in the field of textile materials, can solve the problems of poor anti-ultraviolet durability and poor hand feeling of anti-ultraviolet textiles, and achieve the effects of good anti-ultraviolet performance, increased drape coefficient, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Pretreat the fabric to be sprayed with low-temperature plasma, with a treatment power of 150W and a treatment time of 20 minutes. The humidity of the fabric measured by the YG(B)216-II fabric moisture permeability meter is 90%.

[0027] Step 2: Preparation of TiO 2 EFI solution, TiO 2 The sol is 0.5wt%. If the sol is still clear and transparent after standing for 24 hours, and there is no layering or precipitation, it can be considered that the sol is uniformly dispersed and the system is stable. TiO 2 The sol is used as the electrospray solution because the TiO 2 The dispersion uniformity of the powder in the solution is not high, and it is easy to coalesce and settle for a long time, while TiO 2 The sol itself is nano TiO 2 Uniform dispersion of particles with other forms of TiO 2 Material incomparable affinity.

[0028] Step 3: Place the fabric facing the injection needle spray port of the high-voltage electrostatic spraying equipment. The distance betw...

Embodiment 2

[0032] Step 1: Pretreat the fabric to be sprayed with low-temperature plasma, the treatment power is 250W, the treatment time is 10min, and the humidity of the fabric is 80% as measured by the YG(B)216-II fabric moisture permeability meter.

[0033] Step 2: Preparation of TiO 2 EFI solution, TiO 2 The concentration of the sol is 0.8wt%;

[0034] Step 3: Put the fabric facing the injection needle spray port of the high-voltage electrostatic spraying equipment. The distance between the fabric and the injection needle spray port is 10cm. The electrospray solution is atomized into micron or nanometer particles and evenly loaded on the surface of the fabric. The flow rate of the high-voltage electrostatic spray solution is 0.5mL / h, the voltage is 20kV, and the receiving time is 15min;

[0035] Step 4: drying the textile obtained in step 3 for 20 minutes, and finally obtaining an anti-ultraviolet textile.

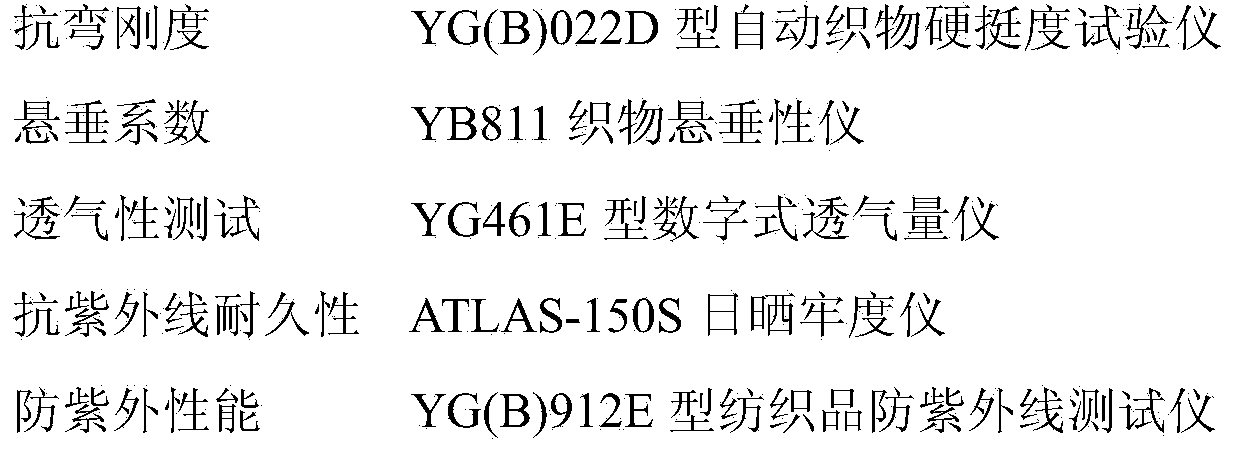

[0036] The hand feel of the fabric is mainly evaluated through the stiffn...

Embodiment 3

[0038]Step 1: Pretreat the fabric to be sprayed with low-temperature plasma, the treatment power is 450W, the treatment time is 30min, and the humidity of the fabric is 70% as measured by the YG(B)216-II fabric moisture permeability meter.

[0039] Step 2: Preparation of TiO 2 EFI solution, TiO 2 The concentration of the sol is 1.5wt%;

[0040] Step 3: Put the fabric facing the injection needle spray port of the high-voltage electrostatic spraying equipment. The distance between the fabric and the injection needle spray port is 20cm. The electrospray solution is atomized into micron or nanometer particles and evenly loaded on the surface of the fabric. The flow rate of the high-voltage electrostatic spray solution is 0.3mL / h, the voltage is 20kV, and the receiving time is 20min;

[0041] Step 4: Drying the textile obtained in step 3 for 30 minutes to obtain an anti-ultraviolet textile.

[0042] The hand feel of the fabric is mainly evaluated through the stiffness test and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com