Technique and system for low-rank coal moisture resource utilization

A process method and low-rank coal technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high water recovery efficiency and failure to consider the recovery and utilization of dry flue gas heat, etc., to achieve heat recovery utilization High efficiency, alleviating water scarcity, and simple technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

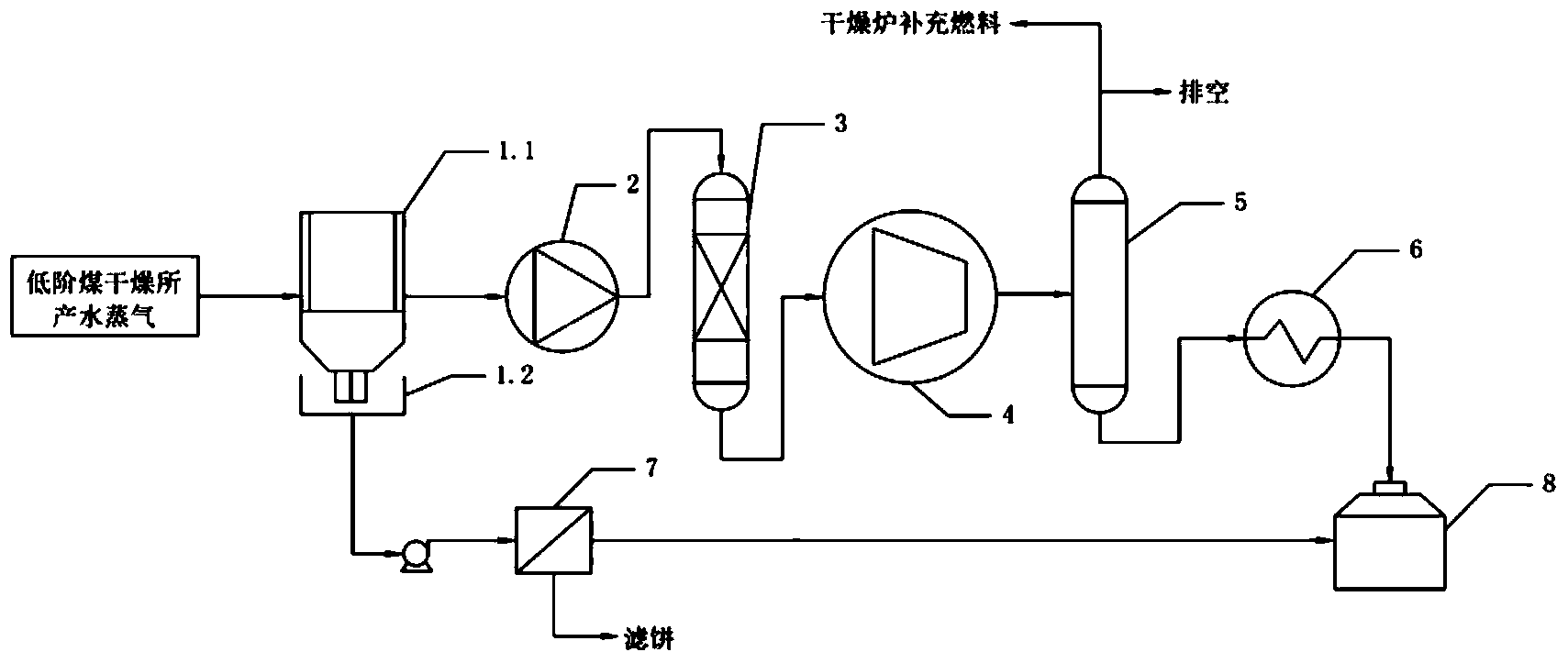

[0027] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

[0028] The cyclone separator 1.1 is sequentially connected with the pressurization system 2, the desulfurization system 3, the low-temperature heat energy utilization system 4, the gas-liquid separation tank 5, the cooling system 6 and the condensed water collection system 8, and a collection pool 1.2 is provided under the cyclone separator 1.1 , the collection tank 1.2 is connected to the condensed water collection system 8 through the filter 7. The low-temperature heat energy utilization system is at least one of a low-temperature power generation unit with an organic working fluid as a circulating medium, or a lithium bromide absorption refrigeration unit, or a low-temperature mechanical work unit. The specific implementation of each unit is an existing mature technology. This will not be described in detail.

[0029] working principle:

[0030]The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com