Preparing and compensating method for temperature drift self-compensating SOI pressure sensor

A pressure sensor and self-compensation technology, applied in the field of MEMS sensors, can solve the problems of limiting the development of the sensor industry, affecting the accuracy of the sensor, poor consistency, etc., to achieve the effect of improving stability and operating temperature range, good product consistency, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

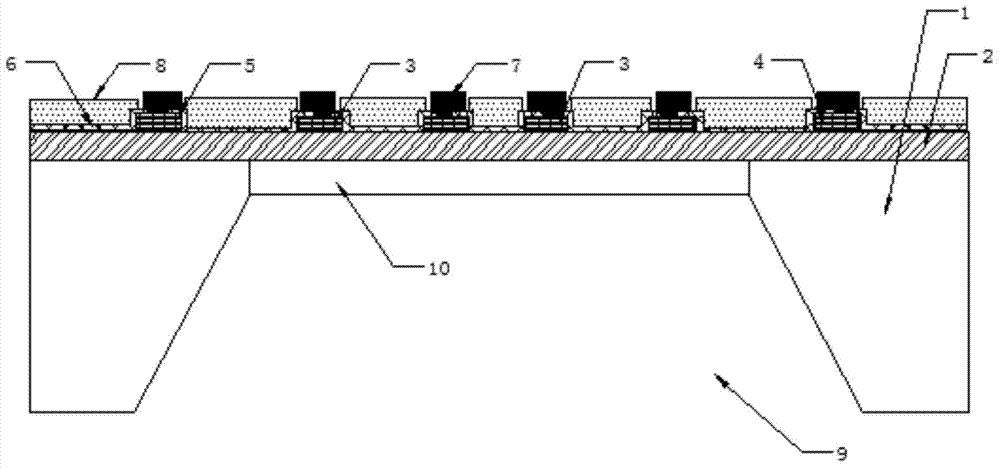

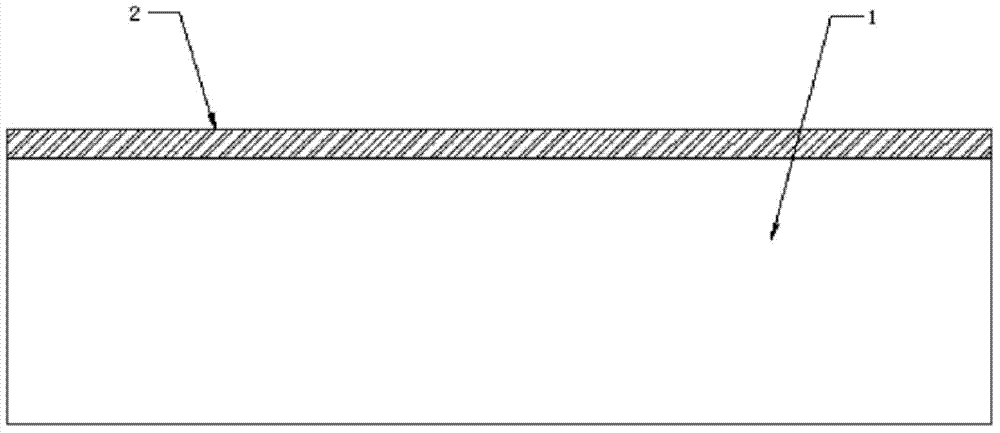

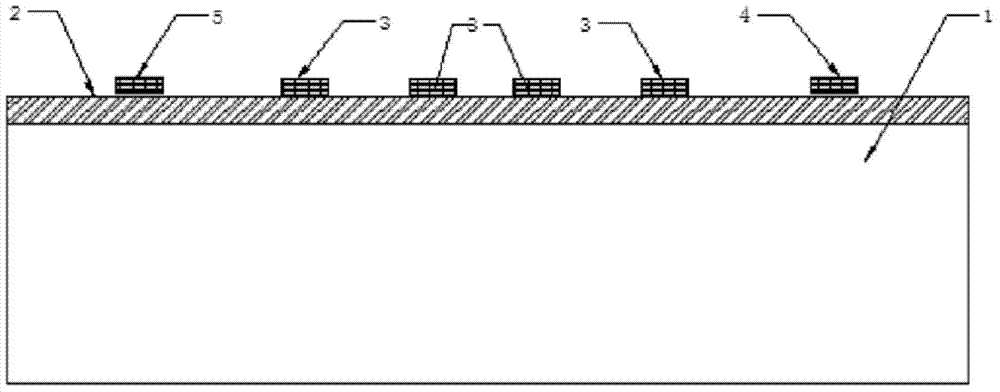

[0027] like figure 1 Shown: In order to improve the measurement accuracy and temperature adaptation range of the pressure sensor, the pressure sensor includes an SOI substrate, on which a conductive material is deposited and a bridge resistance 3 for configuring a Wheatstone bridge is obtained, And in order to reduce the influence of temperature drift, a compensation resistor is provided on the SOI substrate, and the compensation resistor includes a constant voltage power supply compensation resistor 4 or a constant current power supply compensation resistor 5, and a constant voltage power supply compensation resistor 4 is set on the SOI substrate at the same time and the constant current power supply compensation resistor 5, the constant voltage power supply compensation resistor 4 or the constant current power supply compensation resistor 5 can be selected ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com