Preparation and quality control method of liquorice formula granules

A technology of formula granules and licorice, which is applied in the field of preparation and quality control of licorice formula granules, and can solve the problems of different content of chemical components, insignificant difference of first-level infrared fingerprints, interference and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

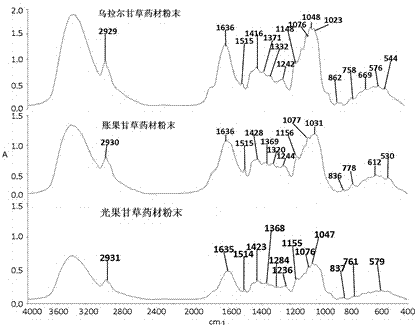

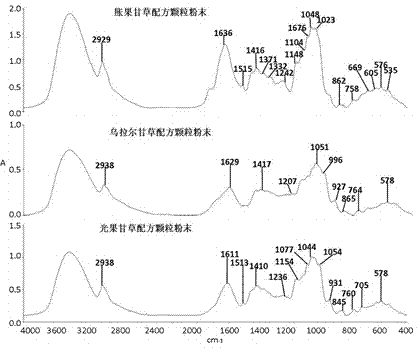

[0055] Example 1: Ural licorice was used as raw material, the following steps were used to prepare licorice formula granules, and its infrared fingerprint was determined.

[0056] Take 215 kg of licorice decoction pieces, chop them up, add water to decoct three times, add 1720 L of water each time, heat and decoct for 1.5 hours each time; combine the three decoctions, concentrate the filtrate to a clear paste with a relative density of 1.08 (80°C), and store it while Filter the heat with a 350-mesh sieve, put it in a batching tank; spray and dry it under the conditions of an inlet air temperature of 175°C, a material pump speed of 500 rpm, an outlet air temperature of 90°C, and an air supply temperature of 40°C to obtain licorice spray-dried powder 485.80kg; dry granulation under the conditions of punching plate aperture 1.50mm, roller motor frequency 40HZ, feeding motor frequency 45Hz, oil cylinder pressure 20bar, and finally licorice formula granules with a particle size of 1...

Embodiment 2

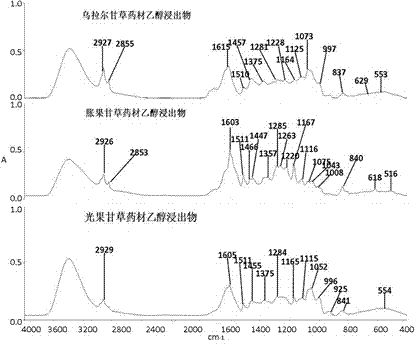

[0059] Example 2: Carry out quality control on the licorice (Ural) medicinal material in the implementation case 1 using infrared fingerprints, the steps are as follows: Weigh 0.5g of medicinal material powder, add 20ml of absolute ethanol, ultrasonically extract for 30min, filter, and take the subsequent filtrate to concentrate to 1ml to obtain a sample solution. Pipette 0.1ml of the sample solution, add it dropwise on 100mg of fully ground potassium bromide powder, place it in an electric furnace and dry it at a constant temperature of 80°C for 3 minutes, take it out, grind it fully and press it into tablets for sample preparation. Measured by Fourier transform infrared spectrometer, measuring conditions: the measuring range is 4000cm -1 -400cm -1 , DTGS detector, resolution 4cm -1 , The number of scans is 16 times, the interference of water and carbon dioxide is deducted in real time during the scanning process, and the relative humidity of the environment is lower than 6...

Embodiment 3

[0061] Example 3: The quality control of the intermediate product licorice spray-dried powder in the preparation process of the licorice formula granules in Example 1 is carried out using infrared fingerprints. The steps are as follows: Weigh 0.5 g of the medicinal material powder, add 20 ml of absolute ethanol, ultrasonically extract for 30 minutes, and filter , Concentrate the filtrate to 1ml to obtain a sample solution. Pipette 0.1ml of the sample solution, add it dropwise on 100mg of fully ground potassium bromide powder, place it in an electric furnace and dry it at a constant temperature of 80°C for 3 minutes, take it out, grind it fully and press it into tablets for sample preparation. Measured by Fourier transform infrared spectrometer, measuring conditions: the measuring range is 4000cm -1 -400cm -1 , DTGS detector, resolution 4cm -1 , The number of scans is 16 times, the interference of water and carbon dioxide is deducted in real time during the scanning process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com