A kind of preparation method of organic/inorganic composite diaphragm of coating type lithium battery

An inorganic composite and lithium battery technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as difficult to degrade, residue discharge, and residual material stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

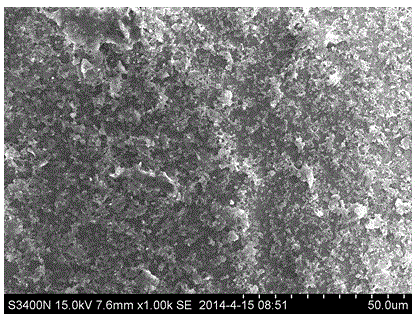

Image

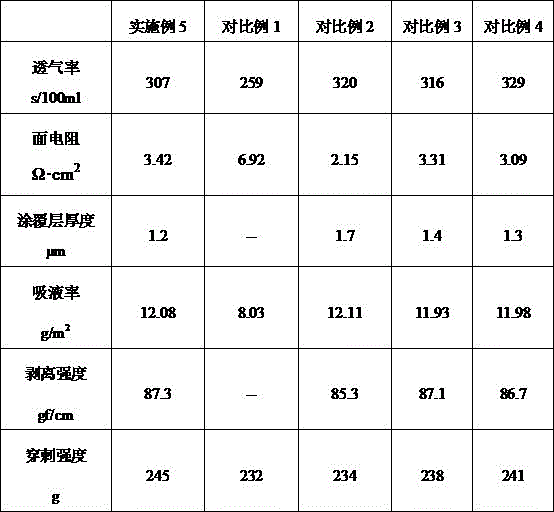

Examples

preparation example Construction

[0032] An embodiment of the present invention provides a method for preparing a coated lithium battery organic / inorganic composite separator, comprising the following steps:

[0033] S01. Configuration of polymer powder pre-dispersion:

[0034] The polymer powder is dispersed in water, and ground in a grinder for a certain period of time to form a polymer powder pre-dispersion.

[0035] S02. Configuration of coating slurry:

[0036] Mixing the polymer powder pre-dispersion with the binder solution to prepare a coating slurry; wherein the mass ratio of the polymer powder to the binder is 5-40:1;

[0037] S03. Preparation of organic / inorganic composite separator:

[0038] The coating slurry is coated on the surface of the polyolefin microporous membrane and dried to obtain the lithium battery organic / inorganic composite membrane.

[0039] In this way, the preparation method of the above-mentioned multi-layer composite diaphragm disperses the polymer powder in the water-solubl...

Embodiment 1

[0049] A preparation method of a lithium-ion battery diaphragm, comprising the steps of:

[0050] S11 Grind nano-sized polyvinylidene fluoride and water with a grinder for 13 hours at a mass ratio of 1:20, and the average particle size of the polymer powder after grinding is 800 nanometers;

[0051] S12 Stir gelatin and deionized water at a mass ratio of 1:9 at 70°C for 3 hours to form a binder. The mass ratio of the pretreated polymer powder to the binder is 14:1 and is configured into a coating slurry by stirring.

[0052] S13: Soak a 20um thick dry-process PP microporous membrane in the slurry for 5 minutes, take it out and dry it in a vacuum oven at 90°C for 30 minutes to prepare an organic-inorganic composite separator.

[0053] The surface of the coated diaphragm is smooth and the improvement is obvious.

Embodiment 2

[0055] A preparation method of a lithium-ion battery diaphragm, comprising the steps of:

[0056] S21 Grind the micron-sized polyvinylidene fluoride-hexafluoropropylene copolymer and water in a grinder for 7 hours at a mass ratio of 1:1, and the average particle size of the polymer powder after grinding is 1200 nanometers;

[0057] S22 Take bone glue and deionized water at a mass ratio of 1:9 and stir at 70°C for 6 hours to form a binder. The mass ratio of the pretreated polymer powder to the binder is 39:1 and is configured into a coating slurry by stirring.

[0058] S23: Soak a 25um thick dry-process PE microporous membrane in the slurry for 5 minutes, take it out and dry it in a vacuum oven at 90°C for 30 minutes to prepare an organic-inorganic composite separator.

[0059] The surface of the coated diaphragm is smooth and the improvement is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com