Coating compositions having chelant functionality

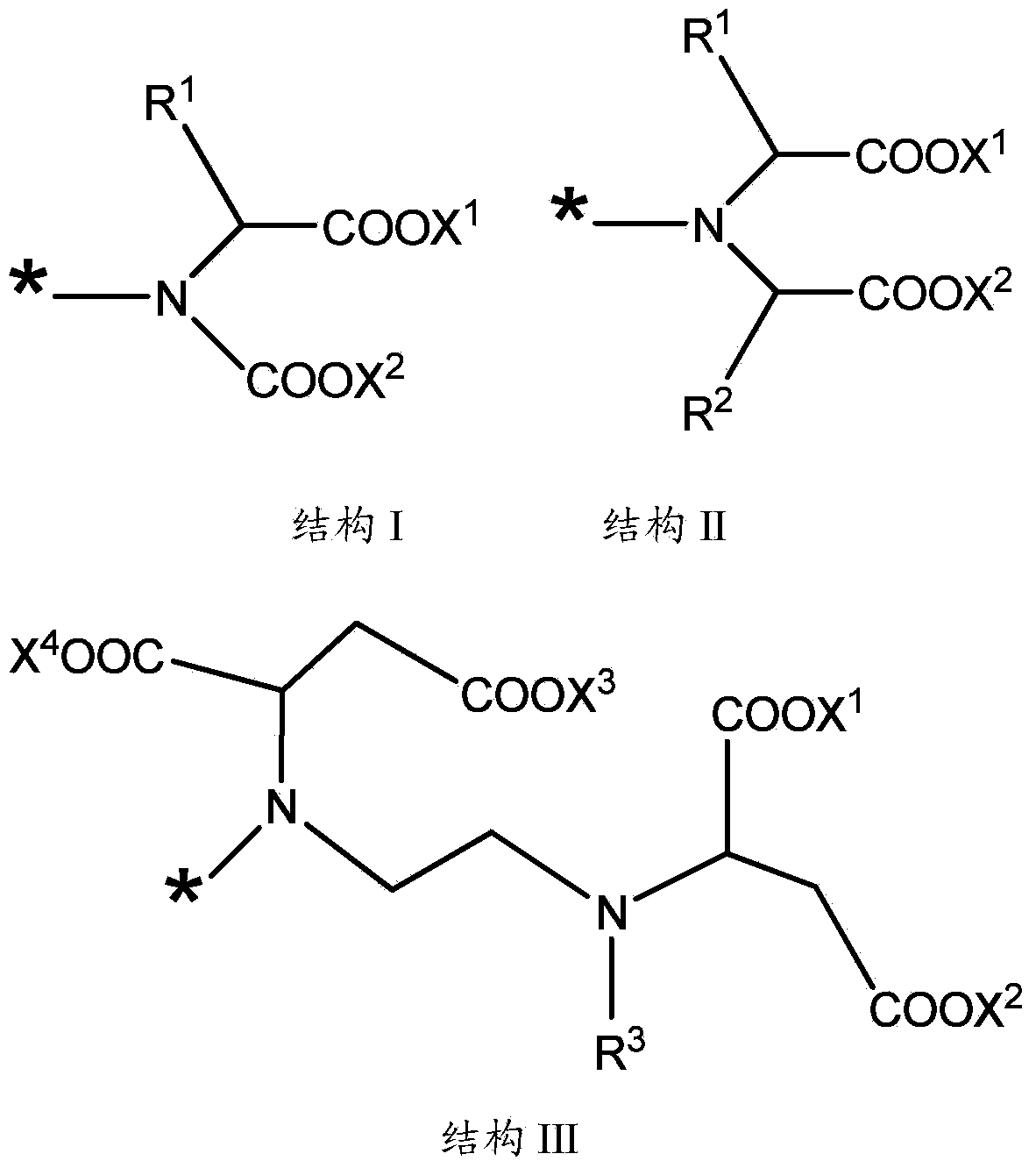

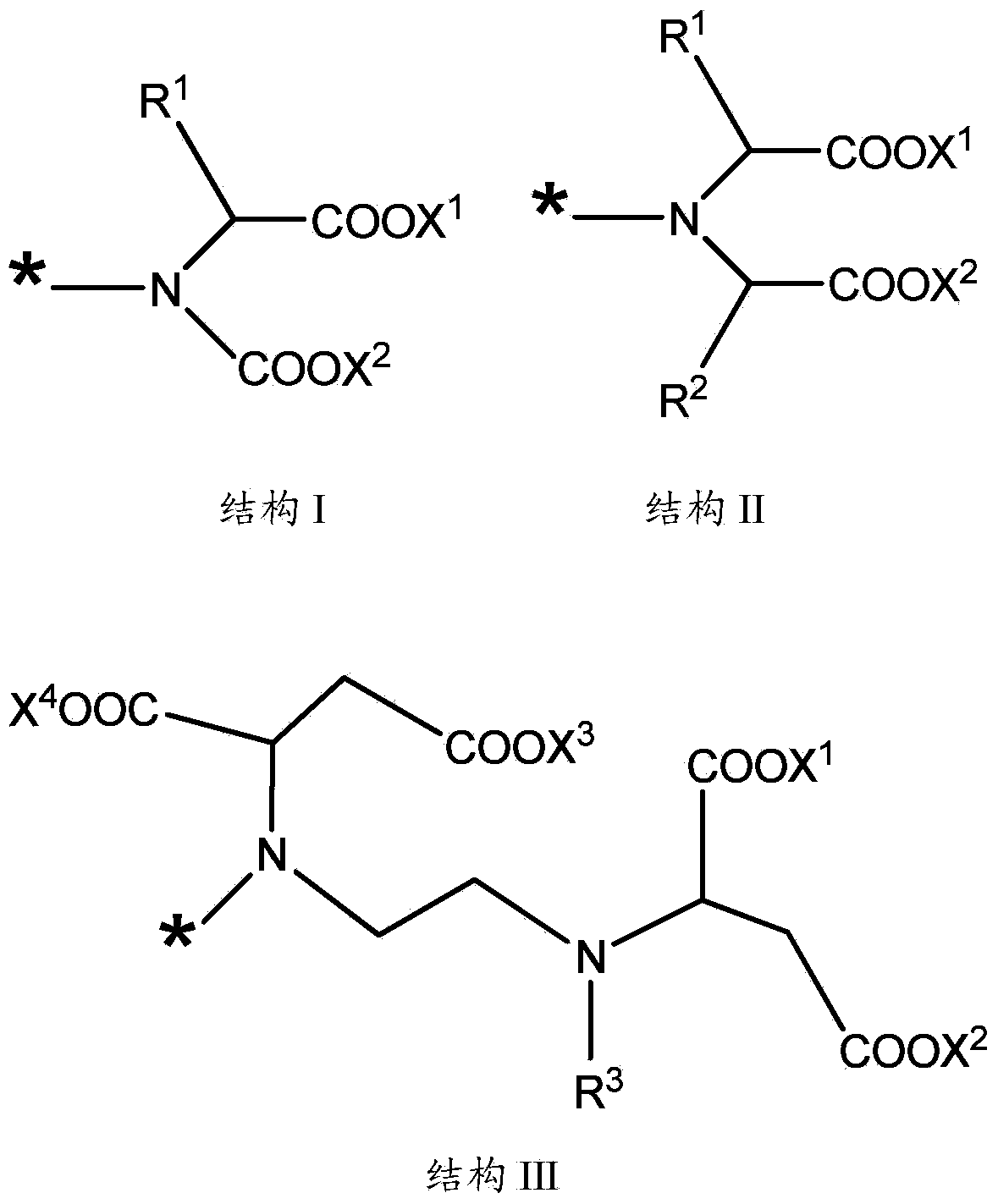

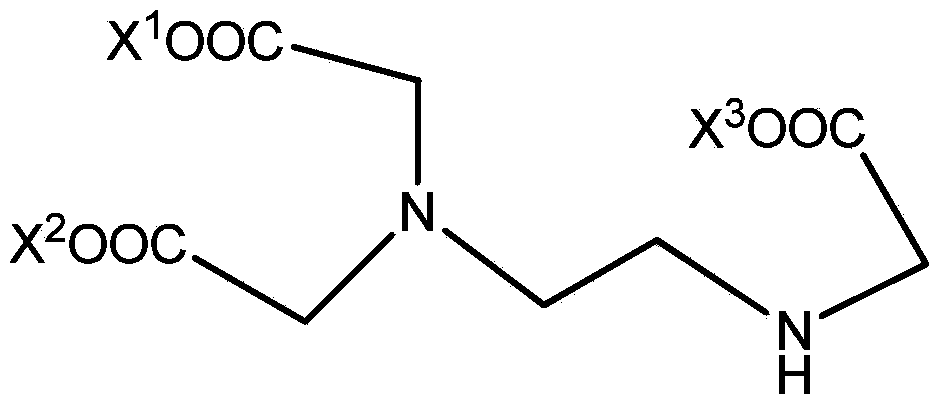

一种螯合聚合物、化合物的技术,应用在涂层、颜料浆料、其他化学过程等方向,能够解决聚合过程复杂性、不理想粘度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] In a suitable reaction vessel equipped with a thermometer, condenser and stirrer, the initial reactor charge was heated to 85-86° C. under a nitrogen blanket while the charges A to M described in Table 2 were prepared. At 85°C, Charge C was added to the reaction vessel together with the rinse and the temperature was adjusted to 80-85°C, then Charge D was charged to the kettle. Within 2 minutes, the onset of polymerization was signaled by a temperature rise of 3° to 5°C and a change in the appearance (color and opacity) of the reaction mixture. When the exotherm ceased, the remainder of the monomer mixture, Feed A, and co-fed catalyst solution Feed F were gradually added to the reaction vessel at about 85°C over 125 minutes. Simultaneously, Feed B was simultaneously added to the reaction vessel at about 85°C over 60 minutes. After 60 minutes, after the end of Feed B, the vessel containing Feed B was rinsed and the rinse was added to the reactor. After the purge, Feed E...

Embodiment 2

[0118] The acrylic dispersion of Example 2 was prepared in the same manner as in Example 1 except that 4.0 wt % of GMA-IDA monomer was added. The polymers were prepared using monomer emulsions containing the monomer ratios described in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com