A kind of super-high-yield cultivation method of flat mushroom

A super high-yield, oyster mushroom technology, applied in mushroom cultivation, cultivation, plant cultivation and other directions, can solve problems such as low yield of oyster mushrooms, and achieve the effects of increasing vitamin content, stable yield, and speeding up the tide turning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] For the indoor cultivation of Pleurotus ostreatus in spring (April), the Gaoping 300 strain (parent species), a commonly used variety in summer, was selected and provided by Jiangsu Gaoyou Edible Fungi Research Institute.

[0031] (1) Culture medium preparation

[0032] The raw materials were weighed according to the following proportions: 400kg cotton husk, 380kg corncob, 155kg lotus seed husk, 30kg corn flour, 15kg lime, 10kg gypsum, 5kg soybean meal, 5kg compound fertilizer, total material 1000kg; Dr. 200g. Among them, the corn cob is crushed into the size of corn kernels or soybeans with a sieve with an aperture of about 2 cm; the compound fertilizer is a high-phosphorus and high-potassium type, and the ratio of various components is: nitrogen: phosphorus: potassium = 12:18:17; It is a product of Nanchang Keda Biotechnology Co., Ltd., and Dr. Gu is a product of Suiyuan Edible Fungi Disinfectant Factory in Zengdu District, Suizhou City.

[0033] Sprinkle the corn c...

Embodiment 2

[0050] For greenhouse cultivation of Pleurotus ostreatus in autumn (September), the commonly used species of Pleurotus ostreatus in autumn was selected for disease-resistant 265, which was provided by Jiangsu Gaoyou Edible Fungi Research Institute.

[0051] (1) Culture medium preparation

[0052] Weigh each raw material according to the following proportions: 400kg cotton husk, 377kg corn cob, 154kg lotus seed husk, 40kg corn flour, 10kg lime, 10kg gypsum, 5kg soybean meal, 8kg compound fertilizer, total material 1000kg; 200g. Among them, the corn cob is crushed into the size of corn kernels or soybeans with a sieve with an aperture of about 2 cm; the compound fertilizer is a high-phosphorus and high-potassium type, and the ratio of various components is: nitrogen: phosphorus: potassium = 12:18:17; It is a product of Nanchang Keda Biotechnology Co., Ltd., and Dr. Gu is a product of Suiyuan Edible Fungi Disinfectant Factory in Zengdu District, Suizhou City.

[0053] Sprinkle ...

Embodiment 3

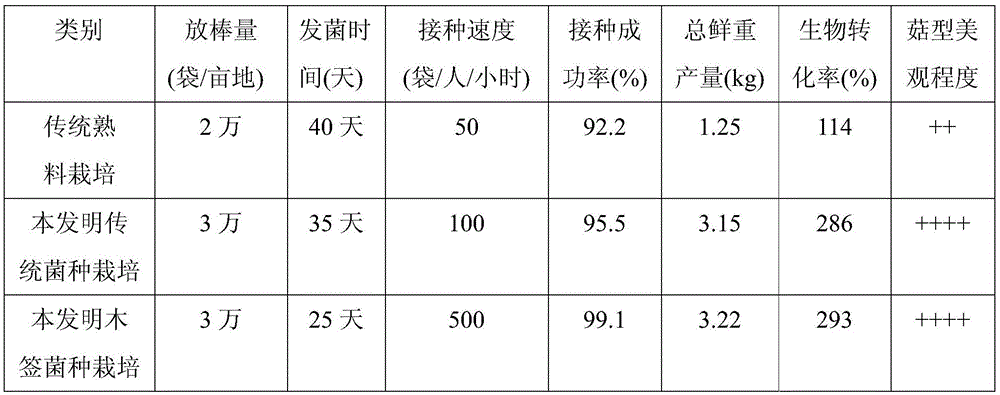

[0072] By adopting the invention to cultivate Pleurotus ostreatus, the production efficiency is increased by 50% compared with the traditional method, the utilization rate of the site is increased by 30%, the fruiting is about 15 days earlier, the success rate is increased by 5-10% compared with the traditional method (it can reach more than 99%), and the biotransformation The production rate will reach 260-300%. The product has thick meat, beautiful mushroom shape and high quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com