Garbage disposal system and method

A garbage treatment system and garbage treatment technology, applied in the field of garbage treatment systems, can solve the problems of substandard extruded fluid and leachate, unstable flow of submersible pumps, and low efficiency of garbage treatment, and achieve high drying efficiency and benefit The effect of aerobic fermentation and anaerobic reaction efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

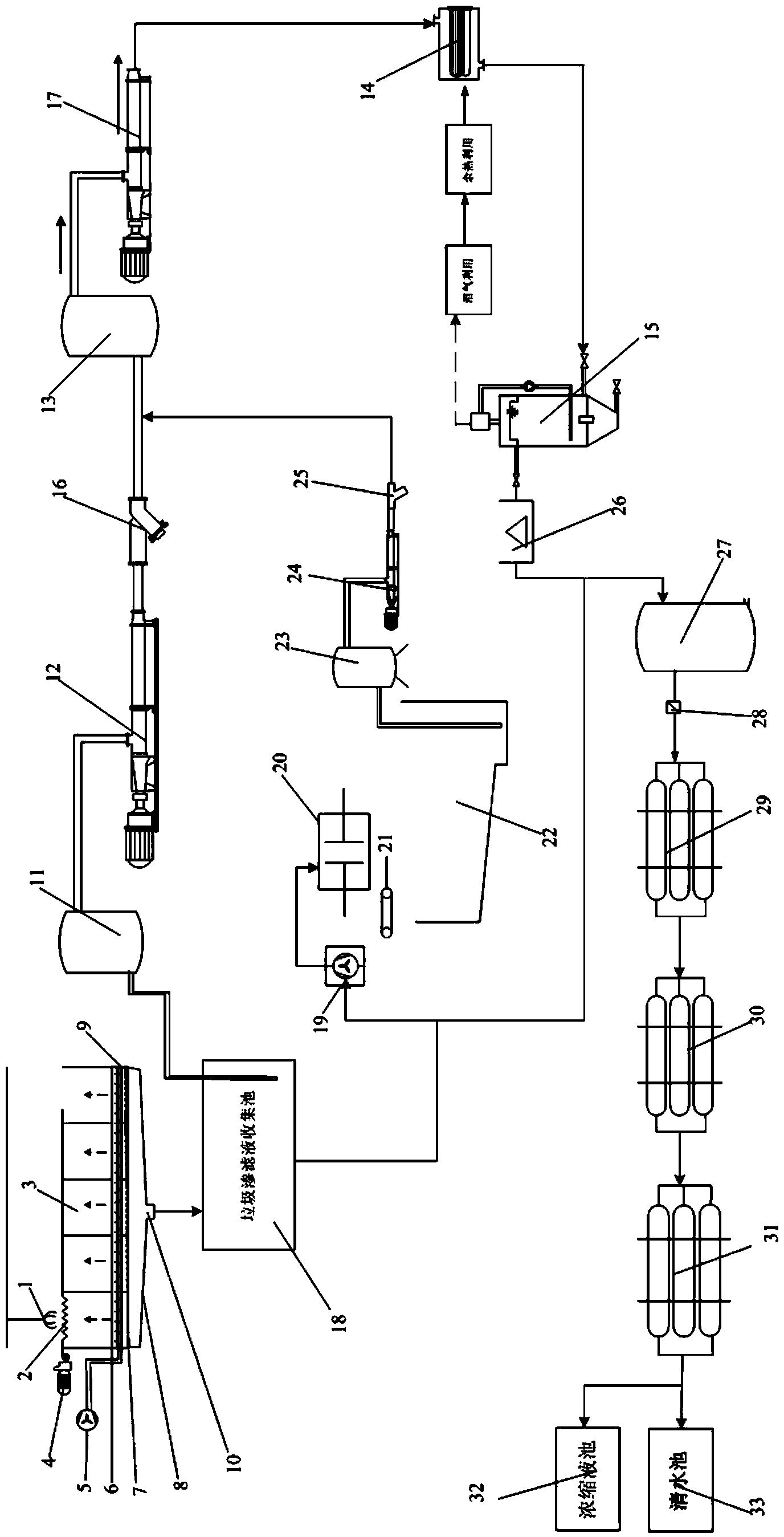

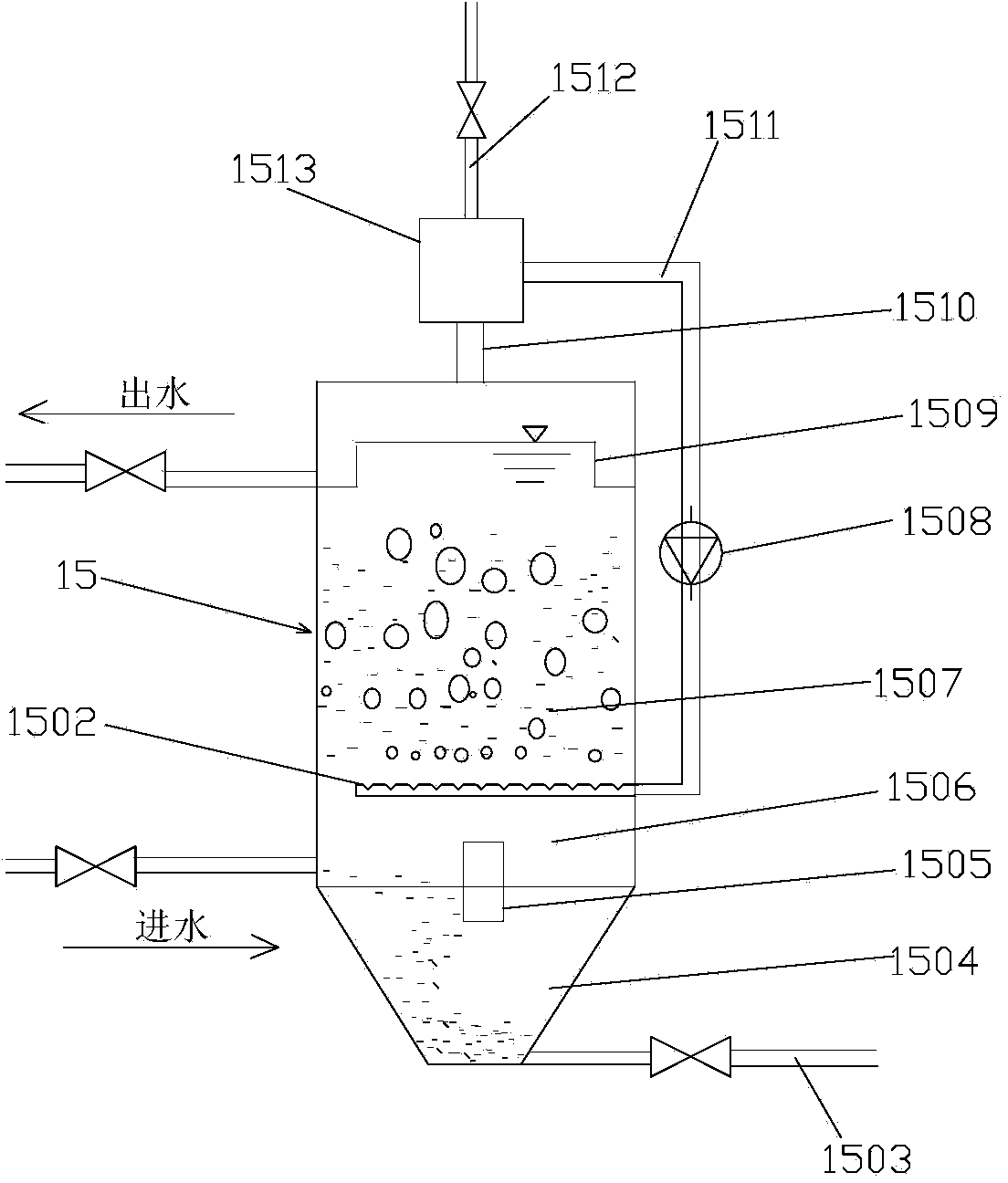

[0044] like figure 1 As shown, the garbage treatment system of the present invention includes a garbage crushing and squeezing device 20, a garbage drying device, a deodorizing device, a filtrate processing device and a garbage screening device. The moisture in the garbage is reduced through the garbage drying device, and leachate is generated during garbage storage and garbage drying. The garbage is crushed and squeezed through the garbage crushing and squeezing device 20 to generate garbage extrudate, and the leachate is treated by the filtrate treatment device. Anaerobic fermentation, nitrification / denitrification and membrane treatment are carried out with the extruded liquid. The deodorizing device treats the odor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com