An electrochemical scale removal device

An electrochemical, scale technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve problems such as resistance rise, reduction of scale removal ability, and increase of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

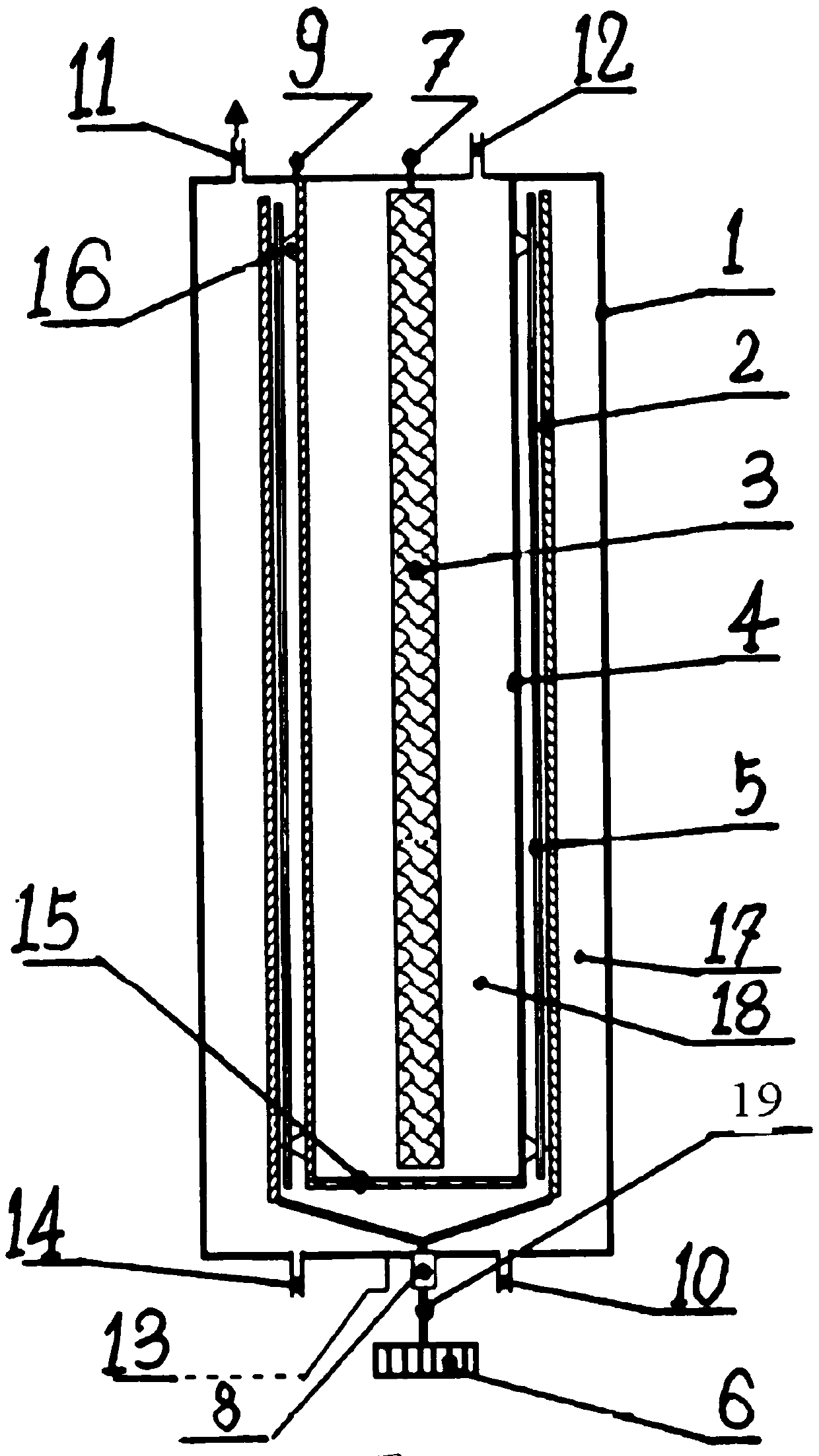

Embodiment 1

[0066] Install two electrochemical scale removal devices in the cooling circulating water system in the form of side flow, and the circulating water volume is 1200m 3 / h, using figure 1 There are two sets of electrochemical scale nucleation unit shown, the total processing capacity of this electrochemical scale nucleation unit is 40m 3 / h, the water to be treated at a temperature of 15-35°C enters the tank body from the water inlet of the tank body, the tank body is provided with a diaphragm, and the diaphragm divides the tank body into a cathode chamber and an anode chamber, and the rotating cathode is located at In the cathode chamber, the diameter of the rotating cathode is 500 mm, the length is 800 mm, and the rotational angular velocity of the rotating cathode is 10 rpm; the anode is in the anode chamber, and the rotating cathode, the anode, the aqueous solution in the tank and the electrolysis power supply form a closed current loop; start the electrolysis power supply ...

Embodiment 2

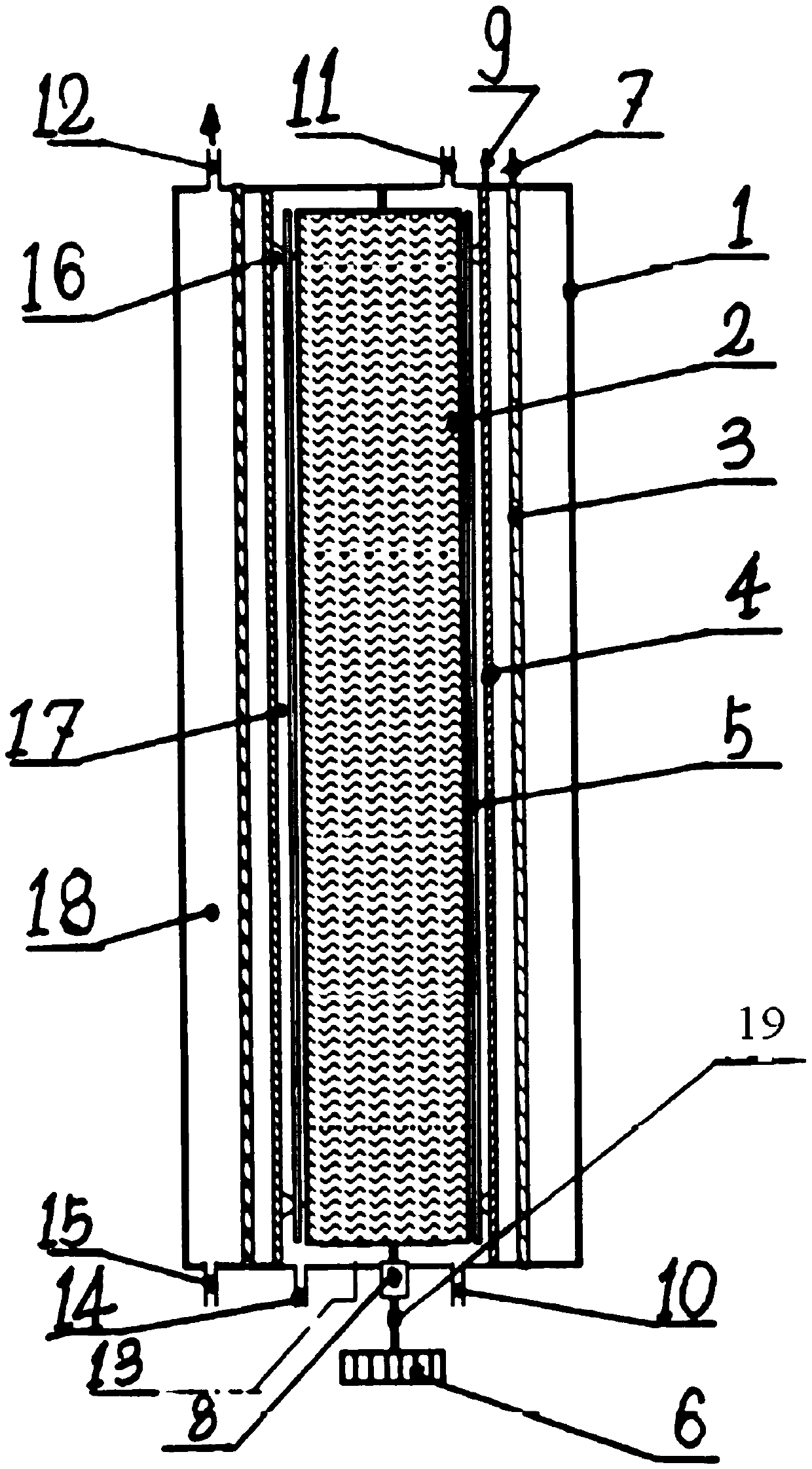

[0073] Install two electrochemical scale removal devices in the cooling circulating water system in the form of side flow, and the circulating water volume is 1150m 3 / h, using figure 2 There are two sets of electrochemical scale nucleation unit shown, the total processing capacity of this electrochemical scale nucleation unit is 40m 3 / h, the water to be treated at a temperature of 20-40°C enters the tank body from the water inlet of the tank body, and the rotating cathode, anode, aqueous solution in the tank body and electrolysis power supply form a closed current loop, and the diameter of the rotating cathode is 500mm, the length of the rotating cathode is 800mm, and the rotational angular velocity of the rotating cathode is 30rpm; start the electrolysis power supply, the current is 40A, and the electrochemical reaction begins to occur near the anode and the rotating cathode; near the anode, water electrolysis produces oxygen and oxygen free radicals, Hydrogen peroxide an...

Embodiment 3

[0080] Four electrochemical scale removal devices are installed in the cooling circulating water system in the form of side flow, and the circulating water volume is 3000m 3 / h, using figure 1 There are four sets of electrochemical scale nucleation unit devices shown, and the total processing capacity of this electrochemical scale nucleation unit is 100m 3 / h, the water to be treated at a temperature of 25°C enters the tank body from the water inlet of the tank body, and the tank body is provided with a diaphragm, which divides the tank body into a cathode chamber and an anode chamber, and the rotating cathode is located in the cathode chamber Among them, the diameter of the rotating cathode is 500mm, the length is 800mm, and the rotational angular velocity of the rotating cathode is 15rpm; the anode is in the anode chamber, and the rotating cathode, the anode, the aqueous solution in the tank and the electrolysis power supply form a closed current loop; start the electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com