Preparation method of S-aryl phosphorothioate

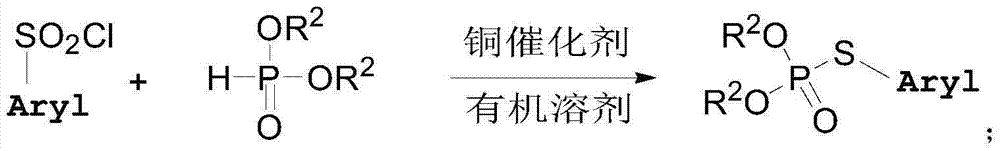

A technology of aryl phosphorothioate and phosphite, which is applied in the field of preparation of S-aryl phosphorothioate, can solve the problems that the synthetic method cannot meet the requirements of industrial production and the like, achieves convenient operation, wide substrate range, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] O, the preparation method of O-dimethyl-S-(4-methylphenyl) phosphorothioate comprises the following steps:

[0024] 1) Take 0.06mmol of anhydrous copper acetate, 0.4mmol of p-toluenesulfonyl chloride, and 2.8mmol of dimethyl phosphite, add 2ml of acetonitrile to make a mixture, put the mixture in a 5ml Schlenk tube, and heat it to 140°C After reacting for 24 hours in an oil bath, cool to room temperature to obtain a reaction solution;

[0025] 2) The reaction liquid obtained in step 1) was directly concentrated to obtain a concentrate, and the concentrate was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 3 (v / v) as a developing solvent to obtain 71 mg of the target product.

[0026] The target product yield of the present embodiment is 76%.

[0027] Carry out NMR characterization to target product, as follows: 1H NMR (CDCl 3 ,400MHz,ppm):δ7.43(dd,J=8.0Hz,1.6Hz,2H),7.16(d,J=7.9Hz,2H),3.82(s,3H),3.79(s,3H),2.34 (s,3H).

Embodiment 2

[0029] O, the preparation method of O-diethyl-S-(4-methylphenyl) phosphorothioate comprises the following steps:

[0030] 1) Take 0.06mmol of anhydrous copper acetate, 0.4mmol of p-toluenesulfonyl chloride, and 2.8mmol of diethyl phosphite, add 2ml of acetonitrile to make a mixture, put the mixture in a 5ml Schlenk tube, and heat it to 140°C After reacting for 24 hours in an oil bath, cool to room temperature to obtain a reaction solution;

[0031] 2) The reaction solution obtained in step 1) was directly concentrated to obtain a concentrate, and the concentrate was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 3 (v / v) as a developing solvent to obtain 76 mg of the target product.

[0032] The target product yield of the present embodiment is 73%.

[0033] Carry out NMR characterization to target product, as follows: 1H NMR (CDCl 3 ,400MHz,ppm):δ7.41(dd,J=8.0Hz,1.5Hz,2H),7.13(d,J=7.9Hz,2H),4.23-4.08(m,4H),2.32(s,3H) ,1.28(t,J=7.04Hz,6H).

Embodiment 3

[0035] O, the preparation method of O-dipropyl-S-(4-methylphenyl) phosphorothioate comprises the following steps:

[0036] 1) Take 0.06mmol of anhydrous copper acetate, 0.4mmol of p-toluenesulfonyl chloride, and 2.8mmol of dipropyl phosphite, add 2ml of acetonitrile to make a mixture, put the mixture in a 5ml Schlenk tube, and heat it to 140°C After reacting for 24 hours in an oil bath, cool to room temperature to obtain a reaction solution;

[0037] 2) The reaction solution obtained in step 1) was directly concentrated to obtain a concentrate, and the concentrate was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 3 (v / v) as a developing solvent to obtain 82 mg of the target product.

[0038] The target product yield of the present embodiment is 71%.

[0039] Carry out NMR characterization to target product, as follows: 1H NMR (CDCl 3 ,400MHz,ppm):δ7.42(dd,J=8.2Hz,1.6Hz,2H),7.12(d,J=8.0Hz,2H),4.11-3.98(m,4H),2.31(s,3H) ,1.70-1.61(m,4H),0.90(t,J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com