A kind of water-based colorful real stone imitation stone coating and its production process

A stone-like coating and colorful technology, applied in the direction of multi-color effect coatings, coatings, etc., can solve the problems of high requirements for production personnel, poor storage stability, and easy crushing of particles, and achieve complex construction and realistic simulation , the effect of reducing the waste of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

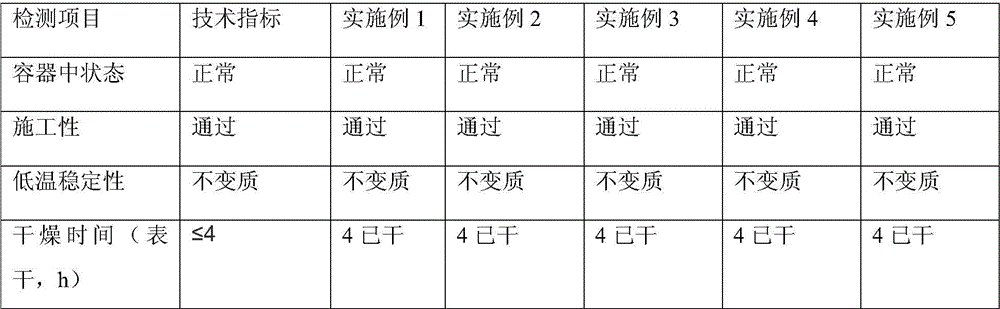

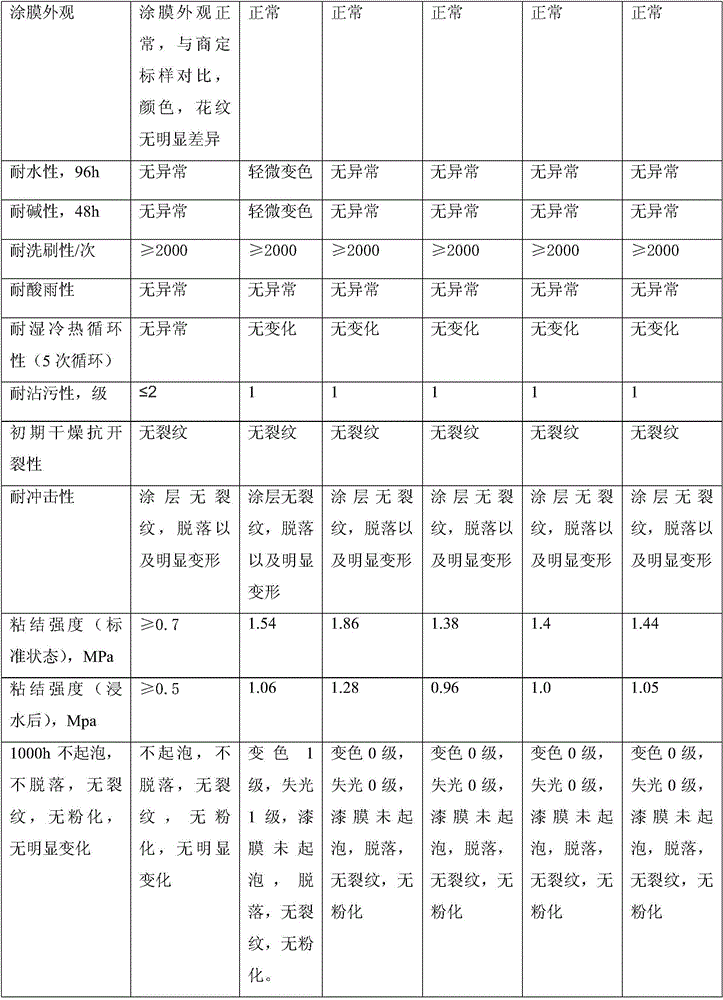

Examples

Embodiment 1

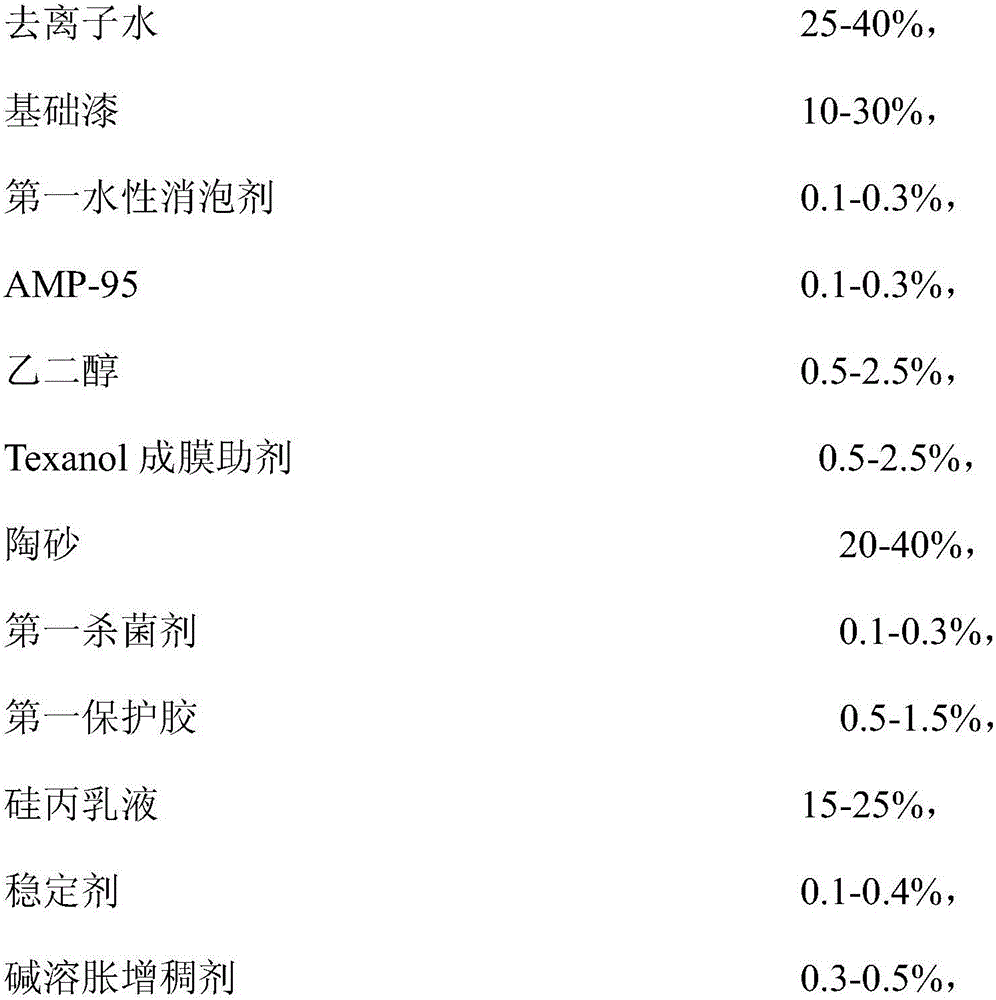

[0036] The formula of the water-based multicolor real stone type imitation stone paint of the present invention is:

[0037](1) Dispersed phase (white): 233g deionized water, 8g HBR250, 2g HE-10K, 3.0g dispersant 740W, 2.0g multifunctional additive AMP-95, 3.0g defoamer A10, 2.0g Casson sterilization Agent LXE, 3.0g water-based antifungal agent AM146, 9.0g rutile titanium dioxide R-902, 300g SLX1048-3 emulsion, 350g snowflake white, 80g 7% S482 aqueous solution, N-3002g, AS63g. Dispersed phase (black): 233g deionized water, 8g HBR250, 2g HE-10K, 3.0g dispersant 740W, 2.0g multifunctional additive AMP-95, 3.0g defoamer A10, 2.0g Casson fungicide LXE, 3.0g water-based antifungal agent AM146, 6.0g rutile titanium dioxide R-902, 300g SLX1048-3 emulsion, 350g snow white, 80g 7% S482 aqueous solution, N-3002g, 3g carbon black, AS63g. Dispersed phase (yellow): 232g deionized water, 8g HBR250, 2g HE-10K, 3.0g dispersant 740W, 2.0g multifunctional additive AMP-95, 3.0g defoamer A10, 2...

Embodiment 2

[0040] The formula of the water-based multicolor real stone type imitation stone paint of the present invention is:

[0041] (1) Disperse phase (white): 227g deionized water, 6g HBR250, 4g HE-10K, 4.0g dispersant 1124, 2.0g multifunctional additive AMP-95, 1.5g defoamer A10, 1.5g defoamer NXZ, 2.0g Casson fungicide LXE, 4.0g water-based fungicide AM146, 5g rutile titanium dioxide R-706, 250g SLX1048-3 emulsion, 415g snow white, 70g 7% S482 aqueous solution, N-3003g, AS65g. Dispersed phase (dark yellow) 227g deionized water, 6g HBR250, 4g HE-10K, 4.0g dispersant 1124, 2.0g multifunctional additive AMP-95, 1.5g defoamer A10, 1.5g defoamer NXZ, 2.0 g Casson fungicide LXE, 4.0g water-based fungicide AM146, 5g rutile titanium dioxide R-706, 250g SLX1048-3 emulsion, 405g snow white, 70g 7% S482 aqueous solution, N-3003g, AS65g, iron yellow 10g. Dispersed phase (light yellow) 197g deionized water, 6g HBR250, 4g HE-10K, 4.0g dispersant 1124, 2.0g multifunctional additive AMP-95, 1.5g...

Embodiment 3

[0044] The formula of the water-based multicolor real stone type imitation stone paint of the present invention is:

[0045] (1) Dispersed phase (white): 160g deionized water, 5g HBR250, 5g HE-10K, 4.0g dispersant 5027, 2.0g multifunctional additive AMP-95, 3g defoamer AM1512, 2.0g Casson fungicide LXE, 4.0g water-based antifungal agent AM146, 12g rutile titanium dioxide R-706, 320g SLX1048-3 emulsion, 416g snow white, 60g 7% S482 aqueous solution, N-3003g, AS64g. Dispersed phase (yellow): 160g deionized water, 5g HBR250, 5g HE-10K, 4.0g dispersant 5027, 2.0g multifunctional additive AMP-95, 3g defoamer AM1512, 2.0g Casson fungicide LXE, 4.0 g water-based antifungal agent AM146, 8g rutile titanium dioxide R-706, 320g SLX1048-3 emulsion, 416g snowflake white, 60g 7% S482 aqueous solution, N-3003g, AS64g, iron yellow 4g. Dispersed phase (black): 160g deionized water, 5g HBR250, 5g HE-10K, 4.0g dispersant 5027, 2.0g multifunctional additive AMP-95, 3g defoamer AM1512, 2.0g Casso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com